i guess this has been discussed before, but can't find any threads...

Very hard, so hard to work, heavy and not as easy to weld.

Andy

Very abrasive (to cut) and dense - it's also very expensive! That discounts it from the locost theme!

At least one person on here is making / has made a stainless chassis. CAn't remember who though!

Also stainless is prone to stress fractures.

quote:

Originally posted by Hellfire

it's very expensive! That discounts it from the locost theme!

Previous thread for information...

Here

907 (but he's a pro welder)!

quote:

Originally posted by andyps

At least one person on here is making / has made a stainless chassis. CAn't remember who though!

I've also started making my chasis in stainless 316 grade . I'm not following the book design because i wanted to make it bigger so most of

the strenghthening will be re-thought out anyway so i'm not all that worried about stress points yet. and i don't think it'll be

heavier that mild steel because of the extra strength of stainless you can afford to go a tad lighter with the sections and you don't have any

weight of the paint(or rust!) .

Mike.

Rescued attachment P1230021u.JPG

Is'nt their a problem with electrochemical reactions of stainless steel and ali? This could cause the stainless to corrode, where pannels are pop rivited on. With steel it's the other way round, the pop rivites rust rather better situation I would suggest??

How structurally sound is it when MIGing Stainless?

I've migged up some small stainless items to good effect...using stainless wire (of course)

Anyone thought of a stainless monocoque as Robin Hood use.

I think there would be less of a problem with fatigue than with a spaceframe.

"Is'nt their a problem with electrochemical reactions of stainless steel and ali? "

Stainless and ally together is a bad idea, but it is the ally which corrodes, and at quite a rate too.

I think as long as they are not in direct contact with each other it would be ok. I'm thinking of using gasket sealer or somthing to that

effect.

Mike

[Edited on 30/6/05 by quattromike]

Bit tricky with Ali riviets? I guess you have to rely on keeping the water out rather than electrical insulation, e.g PU glue aound rivet holes before putting pannel on...

simple solution with a stainless chassis would be to use stainless panels and stainless rivets surely?

Ned.

As formerly seen on the Isonblade - very striking to look at, too.

DJ

[Edited on 1/7/05 by David Jenkins]

quote:

Is'nt their a problem with electrochemical reactions of stainless steel and ali? "

quote:

Originally posted by kreb

Perhaps there's something in the UK air?

I work with achitectural and structural steel as well as foodstuff conveyors and stainless. We have always isolated stainless from both ferrous and

non ferrous metals, including galvanised steelwork using polyeurethane washers and top hats in bolt holes and landing pads for mountings.

Galvanic reaction between stainless and alluminium/steel is very well documented in print as well as the web. Kreb, I hope I never have to walk under

any of your work on a windy day.

I think it's more of a problem between ali and mild steel than ali and stainless i've never heard of it being a major issue.

Is electrochemical only happen when surrounded by flowing water or somthing to that effect ? Thats why we fit alloy anodes to all steel frames for sub

sea use, it eats the alloy first to prolong the life of the steel.

Mike

Hi All.

As I see it, the main problems with building in stainless are twofold.

Firstly the welding. It really has to be Tig, and welds really need to be backed with argon.

All the tee joints on my chassis have a 3 mm hole which allowed the argon to flow through while

it was being welded.

Tig welders, and a plentiful suply of gas doesn't come cheap.

Secondly, a chassis is not just 8 (ish) lengths of box section.

It's all the other bits that for most people would be a problem.

Small quanties of all sorts of round bar and plate are needed, seat belt mounts,

suspension brackets, rack mounts, fuel tank, steering column, the list is endless,

all need to be stainless as well.

I'm lucky, I work with this sort of stuff all the time. I can wander up to the gilly in

my lunch break and just chop a bit off.

Hand making every bit does mean it's a long build, four years so far,

but it will be finished one day, I hope.

Nice to see there's three of us now, or is there more?

ATB

Paul G

Not 316!!!!! stress cracks!!!!

Stainless is 1.5 times heavier you you need to use 22 gauge!

Rgds

Roger

quote:

Originally posted by quattromike

I've also started making my chasis in stainless 316 grade . I'm not following the book design because i wanted to make it bigger so most of the strenghthening will be re-thought out anyway so i'm not all that worried about stress points yet. and i don't think it'll be heavier that mild steel because of the extra strength of stainless you can afford to go a tad lighter with the sections and you don't have any weight of the paint(or rust!) .

Mike.

It doesn't need backing up with argon unless you are planning to use it in a food factory or having a weld test. but make sure you clean all

the welds after or it will rust. Stainless MIG no good on thin sheet TIG weld best.

but make sure you clean all

the welds after or it will rust. Stainless MIG no good on thin sheet TIG weld best.

Rgds

Roger

quote:

Originally posted by 907

Hi All.

As I see it, the main problems with building in stainless are twofold.

Firstly the welding. It really has to be Tig, and welds really need to be backed with argon.

All the tee joints on my chassis have a 3 mm hole which allowed the argon to flow through while

it was being welded.

Tig welders, and a plentiful suply of gas doesn't come cheap.

Secondly, a chassis is not just 8 (ish) lengths of box section.

It's all the other bits that for most people would be a problem.

Small quanties of all sorts of round bar and plate are needed, seat belt mounts,

suspension brackets, rack mounts, fuel tank, steering column, the list is endless,

all need to be stainless as well.

I'm lucky, I work with this sort of stuff all the time. I can wander up to the gilly in

my lunch break and just chop a bit off.

Hand making every bit does mean it's a long build, four years so far,

but it will be finished one day, I hope.

Nice to see there's three of us now, or is there more?

ATB

Paul G

quote:

Originally posted by 907

Hi All.

As I see it, the main problems with building in stainless are twofold.

Firstly the welding. It really has to be Tig, and welds really need to be backed with argon.

All the tee joints on my chassis have a 3 mm hole which allowed the argon to flow through while

it was being welded.

Tig welders, and a plentiful suply of gas doesn't come cheap.

Secondly, a chassis is not just 8 (ish) lengths of box section.

It's all the other bits that for most people would be a problem.

Small quanties of all sorts of round bar and plate are needed, seat belt mounts,

suspension brackets, rack mounts, fuel tank, steering column, the list is endless,

all need to be stainless as well.

I'm lucky, I work with this sort of stuff all the time. I can wander up to the gilly in

my lunch break and just chop a bit off.

Hand making every bit does mean it's a long build, four years so far,

but it will be finished one day, I hope.

Nice to see there's three of us now, or is there more?

ATB

Paul G

erw has to be a certain standard if you buy from a quality supplier as lengths of each batch are tested.

Thin wall st/st is made in exactly the same matter!

If anyone should have such worries use seamless tube for the entire chassis. But it will almost double the price.

Having said that all st/st seamless tubing is annealed so would be better for stress.

Rgds

Roger

While I was teaching myself to MIG weld I would join some bits of erw mild steel tube, as well as I was able, then try to wreck them with a 2lb

hammer.

Although some of my early welds gave up the ghost, and sometimes the metal itself would tear, I never, ever, managed to get a tube seam to split.

The quality of those erw seam welds is extremely high.

David

[Edited on 6/7/05 by David Jenkins]

heh heh!!!!

that's what you think!!!

I happen to be in a unique position regarding the quality of NDT testing of tube. (As well as working for a leading tube manufacturer myself!!!) I

cannot say more on here but Mike R has met the person who has given me this knowledge!!

They say "NDT tested" meaning it has been through an NDT machine. In some cases with one manufacturer, the machine was not switched

on!!!!!!!!!!!!!!!!

In another case, there was an error with operation (which I really cannot go into on here) which had been such for a year and would have caused zero

rejects whatever the quality of incoming tube!!!!

I have already said too much so I will shut up now but believe me, this is through personal experience in recent months!

All being said i'd still rather run around on top of a tig welded stainless frame than a mig welded mildsteel frame , because everyone knows mig

welding is far from an perfect .Or if thay don't they should! Even if it looks ok you don't know it's a sound weld , with cold lap or

lack of fusion common. But with tig if it looks right it most likely is

Mike.

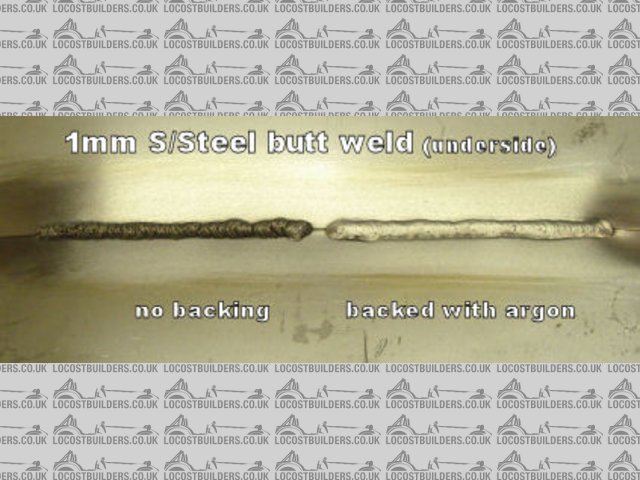

Hi Chaps,

Below, (I hope) is a pic of the underside of a couple of full penetration tig welds,

one with argon backing & one without.

I know which one I'd rather have on my chassis.

Paul G

Rescued attachment chassis welding 001s.jpg

like I said no need to back you have full pen. on both!

do you want to drive it or eat your dinner off it?

Rgds

Roger

quote:

Originally posted by NS Dev

heh heh!!!!

that's what you think!!!

I happen to be in a unique position regarding the quality of NDT testing of tube. (As well as working for a leading tube manufacturer myself!!!) I cannot say more on here but Mike R has met the person who has given me this knowledge!!

They say "NDT tested" meaning it has been through an NDT machine. In some cases with one manufacturer, the machine was not switched on!!!!!!!!!!!!!!!!

In another case, there was an error with operation (which I really cannot go into on here) which had been such for a year and would have caused zero rejects whatever the quality of incoming tube!!!!

I have already said too much so I will shut up now but believe me, this is through personal experience in recent months!

shut up Rorty and stop talking crap as usual.

I can substantiate the claims and I have samples of faulty welded tube in my drawer now!!!!!!!

I can't elaborate on the previous details as to do so would call into question quality at manufacturers who claim to work to international

quality standards (QS 9000, ISO 9000 etc)

If you take the precious moment to look at the point that I was originally making, you'll see what I was driving at

quote:

Originally posted by NS Dev

shut up Rorty and stop talking crap as usual.

I can substantiate the claims and I have samples of faulty welded tube in my drawer now!!!!!!!

I can't elaborate on the previous details as to do so would call into question quality at manufacturers who claim to work to international quality standards (QS 9000, ISO 9000 etc)

If you take the precious moment to look at the point that I was originally making, you'll see what I was driving at

Lies??????????????

I take some offence at that.

They are not lies, unlike some others on here (like you) I don't feed people with bull5hit.

Obviously you have seen a tube welding mill and know the process, and therefore obviously you realise that the welded seams on welded tube are eddy

current tested for flaws. (or sometimes ultrasonically inspected) I have a large degree of involvement with this testing process.

Now turn off the testing machine for a year and see how many rejects you get. For obvious reasons I am not going to name names!!!!!!

Don't be afraid to use welded tubes, of course I use them as everybody else does, just don't assume that they are flawless because they most

certainly are not!

OK Then, so back to the Stainless with Aly topic! I'm not an expert on either but I work in an engineering workshop where we make, with other

things, parts for the sorts of cars we can only dream about and every day I'm shoving aly things into steel things, and vice versa. The aly is

anodised half the time but we often tear into the aly with the steel so it will be 'fresh' aly under the anodised surface.

I saw comments about this a while back so asked someone at work who said it's not a problem with stainless and aly and it's the likes of

Lotus and Mclaren who design these things so I have to hope that they know what they are doing?

I'd use stainless if I could cadge enough from work but it's just to expensive so I'm using the same stuff we all do!

Have a look here.

And this is taken from the Aluminium Federations web site.

"A simple way of avoiding bimetallic corrosion is to isolate the two metals from one another. This can be achieved by good design and where

necessary by inserting an insulating material such as neoprene between the metal/metal contact. This would be important in an application where an

aluminium component is fixed in place with a steel article."

I'll admit that corrosion is slow when the materials are absolutely dry, but as soon as any moisture is added, then corrosion will occur.

quote:

Originally posted by NS Dev

Lies??????????????

I take some offence at that.

They are not lies, unlike some others on here (like you) I don't feed people with bull5hit.

Obviously you have seen a tube welding mill and know the process, and therefore obviously you realise that the welded seams on welded tube are eddy current tested for flaws. (or sometimes ultrasonically inspected) I have a large degree of involvement with this testing process.

Now turn off the testing machine for a year and see how many rejects you get. For obvious reasons I am not going to name names!!!!!!

Don't be afraid to use welded tubes, of course I use them as everybody else does, just don't assume that they are flawless because they most certainly are not!

I'm with NS Dev on this one  i've seen high grade steel box section comeing into my work and having to re-call the manufacturer because of

masive flaws along the seem.

i've seen high grade steel box section comeing into my work and having to re-call the manufacturer because of

masive flaws along the seem.

But back on track, like i was saying i'm thinking of useing instant gasket to seperate the steel from the aluminium would this work? or will it

need to be a thicker material. At the moment i'm doing my rear uprights which are aluminium 6082 T and sierra rear bearing housing made from cast

or even cast from steel i'm not to sure but i will need to keep them seperate some how?

Mike.

quote:

Originally posted by quattromike

I'm with NS Dev on this onei've seen high grade steel box section comeing into my work and having to re-call the manufacturer because of masive flaws along the seem.

quote:

Originally posted by rocket

like I said no need to back you have full pen. on both!

do you want to drive it or eat your dinner off it?

Rgds

Roger

quote:

Originally posted by Rorty

quote:

Originally posted by quattromike

I'm with NS Dev on this onei've seen high grade steel box section comeing into my work and having to re-call the manufacturer because of masive flaws along the seem.

Thank you! All it takes to transform scaremongering, scurrilous lies into believable data, is corroborative evidence!

quote:

Originally posted by NS Dev

How can I put this plainly..........I DO NOT FCUKING WELL TELL LIES YOU SAD TWAT!!!!!!!!!!

quote:

Originally posted by David Jenkins

As formerly seen on the Isonblade - very striking to look at, too.

DJ

[Edited on 1/7/05 by David Jenkins]

nowt wrong with either of them!!

so u waste your gas!

Rgds

Roger.

quote:

Originally posted by 907

quote:

Originally posted by rocket

like I said no need to back you have full pen. on both!

do you want to drive it or eat your dinner off it?

Rgds

Roger

Thought I'd try the old "workshop test for sheet metal butt welds"

As for, "drive it or eat your dinner off it"....

It's nice to have the option

I could become very popular at club bar-b-q's.

atb Paul G

quote:

Originally posted by rocket

nowt wrong with either of them!!

so u waste your gas!

Rgds

Roger.quote:

Absolutely Roger.

Another 10 quid up the chute.

Paul G

NS Dev - 11/7/05 at 07:35 AMquote:

Originally posted by Rorty

quote:

Originally posted by NS Dev

How can I put this plainly..........I DO NOT FCUKING WELL TELL LIES YOU SAD TWAT!!!!!!!!!!

I wasn't aware I had told any lies. Can you refresh my memory please?

You're making a real ass of yourself with your tantrums, and your indignation only falls on deaf ears when you counter accuse myself and others of lying. Not very bright is it?

Oh BTW, I'm not a melancholy vagina and I won't shut up - it's a free forum!

Evidently you cannot read!

I did not say that you told lies, I merely said that I did not appreciate you accusing ME of lying, which is something that I absolutely refute. There are a number of people on this forum that know me personally and know that anything that I claim can be backed up. (otherwise there is little point in claiming it is there!!)

I now suggest that this topic is left, and that in future you do not bother to answer my posts if you merely wish to start a ridiculous argument based on one of your whims.

kreb - 13/7/05 at 01:55 PMI know you folks are deadly serious about it, but I have to say from a yank perspective your exchange is funny as hell just in the choice of language. I haven't laughed so much since I heard Lotus owners called " a bunch of frilly-knickered toss pots".

Keep it light fellas. Life's too short for this silliness.

NS Dev - 14/7/05 at 09:01 PMSorry!

I do normally, just don't like being accused of lying!

DEAN C. - 14/7/05 at 11:01 PMHandbags at dawn ? Ladies!!

Time to cool down perhaps?

Carry on if you like it is quite funny