AndyW

|

| posted on 17/7/11 at 12:23 PM |

|

|

swirl pot plumbing

Just waiting for the swirl pot to arrive. Can anyone tell me please, what connects to the 4 connections n it. Which is feed in, feed out, return etc

etc.

Swirl pot with 4 in/out tubes. Which pipes go to which, and if anyone has pic/diagrams then all the better.

Thanks

A

|

|

|

|

|

Dan.

|

| posted on 17/7/11 at 12:47 PM |

|

|

Link

[Edited on 17/7/11 by Dan.]

|

|

|

bonzoronnie

|

| posted on 17/7/11 at 12:57 PM |

|

|

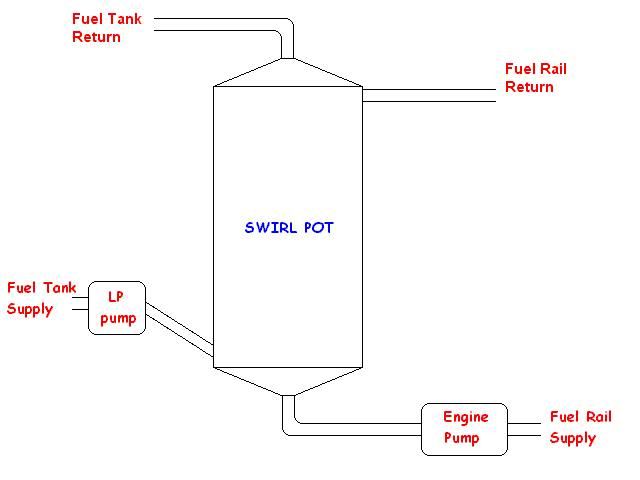

Here's a little diagram for you

Dan beat me to it :but thought I would post it anyway

|

|

|

AndyW

|

| posted on 17/7/11 at 01:16 PM |

|

|

Thanks for the above, so as I understand it I need 2 fuel pumps? I have a fuel pump shown here at the rear of the car:

and then nothing yet in the engine bay. Do I actually need anything else??

Im getting myself very confused with this!!

|

|

|

fimi7

|

| posted on 17/7/11 at 02:01 PM |

|

|

Not sure if that was drawn to scale, my low pressure pump is putting in fuel at the top, was trying to avoid any possibility of the high pressure pump

pushing back on it.

To kind of head off the remarks, this is a mock up of mine, the wood will be replaced with Ali in a couple days

[Edited on 7/17/2011 by fimi7]

--- Ali

|

|

|

SteveWallace

|

| posted on 17/7/11 at 02:54 PM |

|

|

Here's mine in the car, pipe layout as described earlier in the thread. The second picture is shows the low and high pressure pumps. The low

pressure pump is needed to get fuel from the tank to the swirl pot. The high pressure one is between the swirl pot and the injector rail. Sorry that

its not a good pic, the flash decided to stop working...

[img] [/img] [/img]

[img] [/img] [/img]

|

|

|

scudderfish

|

| posted on 17/7/11 at 03:19 PM |

|

|

Think of it that you have two fuel circuits which meet at the swirl pot. One is fed by the low pressure pump and goes to and from the fuel tank. The

other is fed by the high pressure pump and goes to and from the fuel rail. Both circuits have an in and out connection on the swirl pot.

|

|

|

franky

|

| posted on 17/7/11 at 03:53 PM |

|

|

quote:

Originally posted by fimi7

Not sure if that was drawn to scale, my low pressure pump is putting in fuel at the top, was trying to avoid any possibility of the high pressure pump

pushing back on it.

To kind of head off the remarks, this is a mock up of mine, the wood will be replaced with Ali in a couple days

[Edited on 7/17/2011 by fimi7]

Looks very

However from the research i've done the swirl pots should be round and ideally with the 'ports' set at an angle to encourage fuel

swirl and help remove air bubbles.

What effect do square pots have as they effectively become a tank.... don't they?

|

|

|

lsdweb

|

| posted on 17/7/11 at 04:04 PM |

|

|

And here's my old setup - the two lines disappearing through the white glands are the hp feed to the hp filter/fuel rail and the return from the

rail.

Swift Fuel

Wyn

|

|

|

cliftyhanger

|

| posted on 17/7/11 at 05:57 PM |

|

|

the return to the tank definitely needs to be at the highest possible point. And the high pressure pump feed at the lowest.

Have heard it suggested that fitting a restrictor in the tank return can be beneficial, stops the low pressure pump working flat out all the time.

And yes, round with offset pipes best, but I suspect a square one will be nearly as good.

|

|

|

AndyW

|

| posted on 17/7/11 at 07:45 PM |

|

|

So I need a low pressure pump aa well? Better start saving up a few more beer tokens

|

|

|

rusty nuts

|

| posted on 17/7/11 at 07:49 PM |

|

|

quote:

Originally posted by AndyW

So I need a low pressure pump aa well? Better start saving up a few more beer tokens

From your photo it looks to me like you already have a low pressure pump and not a high pressure ??

|

|

|

AndyW

|

| posted on 17/7/11 at 08:07 PM |

|

|

Totally confuddled now. When i was at the factory the other week they used just the pump I've got, and a swirl pot with 4 in/outs.

Will call them tomorrow to find out exactly whats what!!

AAAARRRGGGGHHHHH

|

|

|

rusty nuts

|

| posted on 17/7/11 at 08:53 PM |

|

|

Any markings on your pump? Does it tick? if it does then it's a low pressure pump. Yours looks like a Facet low pressure pump for carbs

|

|

|

AndyW

|

| posted on 17/7/11 at 09:51 PM |

|

|

Here are the markings I can find on the pump, not brill pic but it is late!!

|

|

|

rusty nuts

|

| posted on 18/7/11 at 06:45 PM |

|

|

A high pressure should put out around 3 to 4 bar whereas a low pressure would be around 0.3 bar , about 4 or 5 PSI

|

|

|

AndyW

|

| posted on 18/7/11 at 09:25 PM |

|

|

Got it sorted. I was being daft and totally missing the point. The pump I have is "obviously" my low pressure pump which feeds the swirl

pot. I then (about to buy) add my high pressure pump to feed the injector rail from the swirl pot.

Sounds like I know what Im doing

Thanks for all the reply's, and yes Mel your are right!!!

|

|

|

rusty nuts

|

| posted on 19/7/11 at 06:25 PM |

|

|

Glad it's sorted.

|

|

|