dyno

|

| posted on 2/11/20 at 10:11 AM |

|

|

Tube thickness Haynes chassis

Hallo to all.

I'm new on this site and have plans to build a Haynes Roadster using their book and plans.

Unfortunately one thing is not fully clear to me. The main tubes are 25x25mm 16swg. We use metric sizes in Belgium, we have 25x25x1,5mm (wall

thickness 1,5mm) or 25x25x2mm.

As far as I can find out, 16swg is 1,626mm. We don't have 1,625mm wall thickness. It's 1,5mm or 2mm

To cut it short, what's the wall thickness of tubes most builders are using?? 1,5mm or 2mm ??

thanks in advance

Dirk

|

|

|

|

|

40inches

|

| posted on 2/11/20 at 10:23 AM |

|

|

1.5mm is the normal gauge

|

|

|

dyno

|

| posted on 2/11/20 at 10:30 AM |

|

|

Thanks a lot

That's quite thin wall stuff. I really thought it would be 2mm.

Are these chassis strong enough to handle high power outputs in standard form?

|

|

|

40inches

|

| posted on 2/11/20 at 10:56 AM |

|

|

2mm would be overkill and very heavy.

The Jag V6 in mine has 270 ish BHP and the chassis is still in one piece

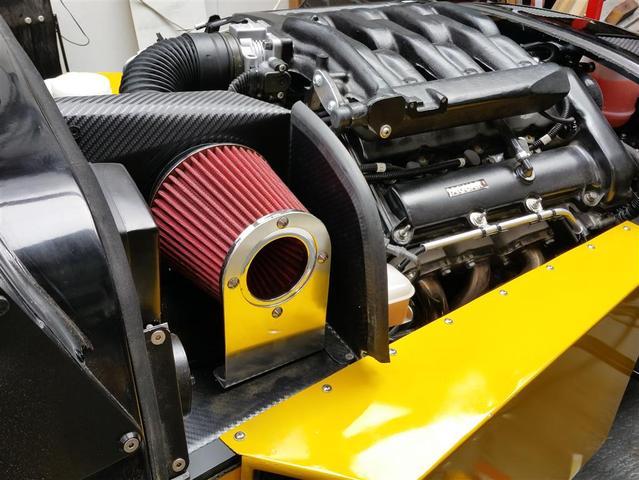

Description

|

|

|

dyno

|

| posted on 2/11/20 at 11:00 AM |

|

|

Nice build car

I like the air outlet's. Was it home build or can you order them ?

|

|

|

40inches

|

| posted on 2/11/20 at 11:07 AM |

|

|

1.2mm ally sheet, easy to fabricate and they really work well. They also let air in at the front

Description

https://www.locostbuilders.co.uk/photos.php?action=gal&user=40inches&folder=AJ30

|

|

|

dyno

|

| posted on 2/11/20 at 11:13 AM |

|

|

Nice done

|

|

|

nick205

|

| posted on 2/11/20 at 01:00 PM |

|

|

1.5mm wall thickness is the standard wall thickness. Strong enough chasis and easy enough to weld. 2.0mm wall thickness will make for a heavy chasis

and more effort to weld as well.

|

|

|

big_wasa

|

| posted on 2/11/20 at 01:10 PM |

|

|

Ive seen some daft power and torque figures put through a book chassis.

If you are going really daft there are some bits you could beef up with extra triangulation.

|

|

|

MikeR

|

| posted on 2/11/20 at 01:34 PM |

|

|

As i understand it (and backed by the link here) 16 gague tolerance is between 1.4 and 1.6mm steel. 1.5 being average.

(linky - https://www.engineersedge.com/materials/sheet_metal_gauge_tolerances_chart_13178.htm)

1.5mm steel is therefore what you want

|

|

|

procomp

|

| posted on 2/11/20 at 03:54 PM |

|

|

As above.

Check with your supplier EXACTLY what he is supplying and measure it to make 100%.

The tolerance on tubing is not good these days as they roll material to the EXACT min tolerance.

16g usually comes as 17.5G thees days and if you order 2mm you may find it is actually the equivalent of 16.5G which is what most are now using as

GENUINE 16G from quality suppliers is now very expensive.

For RACE chassis i order 1.5mm BUT that can end up being as thin as 1.35mm. No problem on a race chassis with all the extra bracing and full rollcage

Etc but for a std type road chassis it will lead to issues.

|

|

|

dyno

|

| posted on 2/11/20 at 05:48 PM |

|

|

quote:

Originally posted by procomp

As above.

Check with your supplier EXACTLY what he is supplying and measure it to make 100%.

The tolerance on tubing is not good these days as they roll material to the EXACT min tolerance.

16g usually comes as 17.5G thees days and if you order 2mm you may find it is actually the equivalent of 16.5G which is what most are now using as

GENUINE 16G from quality suppliers is now very expensive.

For RACE chassis i order 1.5mm BUT that can end up being as thin as 1.35mm. No problem on a race chassis with all the extra bracing and full rollcage

Etc but for a std type road chassis it will lead to issues.

That's indeed what I see here, 25x25x2mm is in reality 25x25x1,8mm. Reason why I thought it was 2mm I had to order.

PS: do you build you road chassis out of 2mm and the race chassis only in 1,5mm ??

|

|

|

dyno

|

| posted on 3/11/20 at 01:24 PM |

|

|

BTW, does anyone has the correct weight of a full Haynes Roadster chassis, build with 1,5mm (16SWG) tubes. Less wishbones etc.. bare chassis ?

thanks

Dirk

|

|

|