Lack of Fuel

matt_gsxr - 21/7/09 at 10:31 PM

Hi there folks,

I think I have a problem.

I think I know what the problem is.

I have a few thoughts on what to check, but would appreciate your thoughts/sanity check.

I am running carbs, but have a megasquirt that I am using for datalogging. This is connected to a LC-1 which can measure the Air-Fuel-Ratio.

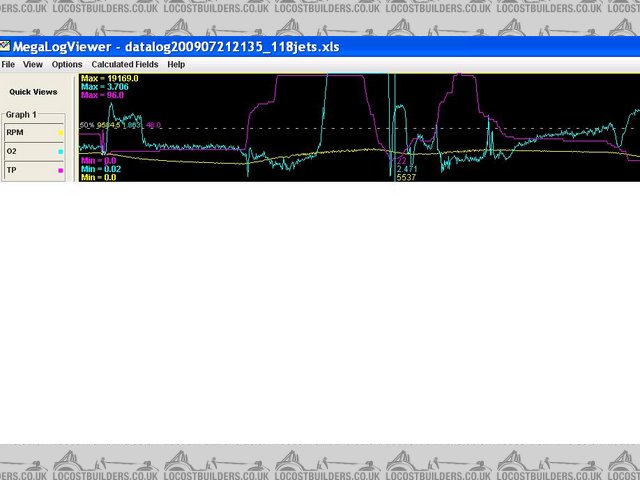

Here is a bit of output. Throttle position is purple (the closed throttle presently reports as 25%, sorry, it is a bodge on the pedal), RPM is

yellow, and AFR is pale blue (this is actually O2, but top of plot is AFR>17, super lean, bottom of plot is AFR around 10).

mega-log-dump

From this I deduce that when I go to WOT everything works fine (for a while) then suddenly it goes lean. From this I deduce that I have a fuel flow

problem. You can see later that for short bursts of acceleration that this isn't a problem.

So. I believe that I have a fuel flow problem.

Let me describe my set-up.

I have a tank with a filter and then the fuel pump (zx9 pump for bike carbs), then I have a run of 8mm B&Q gas pipe to the engine bay, where I

have a second fuel filter before the carbs.

The tank is vented using a Think-Automotive 1-way valve (with one of those clever balls in it and a bit of hosing, because I wanted to vent away from

the tank, not sure why now).

At startup the pump ticks away nicely.

So, assuming you are with me on it being fuel flow problem (if not then sing out), then I have the following list of possible candidates:

Problem with tank vent (easily checked by removing it or leaving the cap loose temporarily).

Problem with pump (dodgy pump)

Problem with power-supply to pump (heard of this before)

One or more fuel filters blocked

Filter after fuel pump shouldn't be in system.

Some "funny" LC-1 problem

So my present plan of action is:

1) datalog with the fuel cap partially removed.

2) Do a flow test, I have the Dave Walker book that gives suggested required flow rates (don't flow test for too long, as the pump can overheat,

I know). I can then have a look at removing/replacing filters.

Any other thoughts?

Matt

Steve G - 21/7/09 at 10:38 PM

You may also want to check the carbs themselves if it isnt any of what you have mentioned. Check the floats and needle valves all operating correctly.

You could also add swarf partially blocking the lines at some point i guess.

luke - 21/7/09 at 10:47 PM

im no expert but im sure i remember reading a thread a few weeks ago where someone was having flow problems and it was mentioned he needed a 2 way

breather valve, to allow air in and gases out.

dont quote me on it! just rings a bell!

matt_gsxr - 21/7/09 at 11:00 PM

Steve,

Good thought. I think that I can eliminate the carbs.

I have had them apart a few times and they are nice and clean. Further I have 4 carbs, and reading the plugs suggests that they are all behaving the

same.

So either I have some weird multiple failure or they are alright.

Luke,

I thought mine was a 2 way breather. Gas in or out, but not fuel out. I may have installed it wrongly, the breather valve is definitely on my hit

list of things to investigate. I will hunt down that thread.

thread-found

FYI I have a TRV45

[img]http://www.thinkauto.com/tbvcolour.htm[/img]

http://www.thinkauto.com/tbvcolour.htm

jambojeef - 22/7/09 at 04:05 PM

It may not be fuel flow.

If say in a high gear roll on you floor the throttle and the carbs are at WOT.

The slides stay down to increase the speed of air flow across the venturi to "artificially" richen the mixture and rise according the rate

at which the demand and supply are equalising.

In that case all is normal according to your trace apart from that once the engine demands the full amount of air that carb can supply you are a

little lean.

I would lift the needles a notch and try again.

If the AFR comes down then you know theres no supply issue. If it looks the same then it could be supply or you need to lift another notch and try

again.

Its easy to assume something when we fault-find in our cars but from bitter experience, try the free stuff first!

I hope that makes sense, I dont think ive explained it very well but it makes sense somewhere between my ears!

Geoff

[Edited on 22/7/09 by jambojeef]

matt_gsxr - 22/7/09 at 04:40 PM

Geoff,

Very interesting thought.

I understand what you are suggesting. So in this case it would be RPM related.

I will try running with the filler cap a bit open, as that is even easier than moving the needles (free stuff first!). And then connect the MAP

sensor on the Megasquirt to the carbs to see what MAP pressures (and hence needle heights) I am running.

I love a bit of datalogging, you can do great stuff with the Megasquirt. You can use the MAP sensor to look at air pressure in the airbox to look for

restrictions.

You can connect the temperature sensor feeds to oil pressure sensors to look for RPM related oil surge, there is no end to the fun. One day I might

even connect it to fuel injection!

Matt

jambojeef - 22/7/09 at 06:24 PM

Datalogging like that is great - I nearly scored a Squireel datalogger from Uni when i was a researcher whcih are fantastic bits of kit if a little

clumsy looking these days.

Just one word of caution - before you draw too many conclusions from the AFR make absoultely sure there are no air leaks on either inlet or exhaust

side.

Widebands are accurate but only as accurate as where their are placed / what they are fed!

Best of luck and let us know how you get on,

Geoff

matt_gsxr - 23/7/09 at 10:51 PM

Hey there,

I wrote a lengthy reply yesterday but for some reason (maybe I wasn't logged on) it hasn't appeared.

Anyway. The long and short of it.

Pump was flowing fine, but not flowing fine into the engine bay area. Deduced that it was 8mm copper pipe related, which turned out to have been

squished. I fixed that. Then I tested the flow with a milk carton and stop-watch (originally 1pint/min, after the fix 1.6litre/min). The earlier

number is a bit low for a 140bhp engine (pints/bhp/hour = 0.5 according to D. Walker, although his book is confusing on this owing to typos and

such).

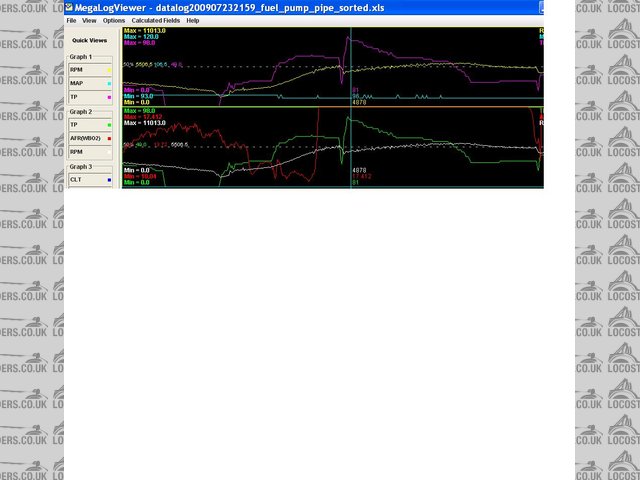

So, I was confident that I had fixed the problem. Took the car for a drive today, and initially all the numbers were nice. AFR about 12 (a bit rich,

but safe). Then later in my little jaunt I got the same phenomenon as before. High AFR peaks

megalog after fuel pump fix

I should have opened the tank when I go t out and listened, but I didn't (what a dolt).

Maybe I am suffering from venting problem (as well). I wasn't running with the fuel cap off, as I thought I had fixed the problem.

Interestingly when the AFR goes high, then the RPM trace goes a bit noisy. I assume this is related to some kind of miss-fire, and hence does this

mean it is one cylinder only. Perhaps I need to do a "plug-chop" when the AFR is high to determine if a single cylinder is the culprit.

All this is a bit hazardous on the queens highway! This does indicate (to me) that this is in some way "real" (i.e. not extra air in the

exhaust).

I am wondering whether one of the throttle slides is sticking. Perhaps I can put a digital camera into the air-box and investigate (how cool would

that be for datalogging).

I guess I need to check the venting of the tank again as once I saw the fuel flowing badly I jumped to a conclusion. It could easily be both fuel

pipe and venting. Looks like a nice weekend job.

Actually, I logged the air pressure in the airbox and it didn't drop below 93 (ambient is 96), I think I can improve on that by moving the inlet

(although I am not anticipating postive pressure from the ram effect). I can use the same sensor (MAP sensor) to detect pressure in the fuel tank

(how cool would that be!). I am a scientist by day, which is why I like this stuff!

Matt

SPYDER - 25/7/09 at 08:32 PM

Hi Matt, just a thought.

We had a vaguely similar problem on our TR7 V8 race car many moons ago.

We eventually found that air was being drawn IN to the fuel line where the fuel filter was ie. upstream of the fuel pump.

At no time did fuel leak out.

The car ran fine at low throttle openings but less so as more throttle was used.

At WOT it would bog down terribly.

Can you bypass the filter, ie. connect the pump direct to the tank, just as an experiment?

( a different) Geoff.

mad-butcher - 25/7/09 at 10:10 PM

Not too dificult to do a plug chop safely on your local motorway, just chop coming up for a junction and freewheel onto hard shoulder of slip road.

that way your not checking the plugs on the motorway itself. Junc 1 on mines reasonably quiet at 8pm

tony

matt_gsxr - 25/7/09 at 11:13 PM

I have investigated running with the fuel cap wedged open and it makes no difference. So it isn't vacuum in the tank.

They say a picture tells a thousand words. Here is a picture, I don't understand the words!

front = left fueling probs

Plugs are in the order that they are in the engine. The one on the left is the front one, the one on the right the rear.

I think that I am seeing a progression of fueling from the front one, which is getting too little fuel, to the rear one which is getting a bit too

much.

[Update] Actually I had assembled carb 1 wrongly. The spring on its jet needle was binding and so that slider wasn't going up and down. Not

enough air and mega rich.

[End of update]

I had the fuel lines set up so that the flow went into a T-piece that fed the no. 1 and no. 2 carbs (back ones, far right in the photo above). Then

off this T a second leg fed the front carbs. I have seen the error of my way here (both the acceleration forces, and the pressure gradient in the

pipe are both favouring flow to the back cylinder), this is a bad thing to do as a better design is to have "all cylinders fail equally" as

it will be more obvious and easier to diagnose.

I have re-piped it with a T-piece between the two pairs of carbs. This doesn't solve the whole problem (which is insufficient fuel) but it is a

good thing to sort out.

So, I remeasured the flow-rate from the fuel pump after the last filter and it was low again. I replaced that filter with a new one (the biggest that

I could find) and the flow was still low, I took the filter out completely and it is now 900ml / min. although this can only drop when it supplies

fuel past the float valves and such. My calcs (based on 0.54 pint/bhp/hour, which is a figure I am not confident of) suggest I would need 760 ml/min

for 150bhp.

I don't understand why it is so much less than it was yesterday. I am also surprised how the flow rate depends so strongly on the back pressure,

it isn't like a small filter should have much effect. I think that my flow-rate may be high enough now, but it is at best boarderline, which is

annoying/scary.

I will get a replacement pump. Not zx9 this time. To be fair if you WANTED to buy a dodgy fuel pump then e-bay would be the best place to look, so I

may have a slightly weak one.

[Update]

I got a replacement pump zzr1100-D1. The old pump seems to be fine. The connectors on the back are a bit carbonized, but it works fine when I pump

cold water around. Interestingly you can connect the power backwards and it still works nearly as well! Flow rate is now 2pints in 55seconds (no

filter, but at a place where the carbs would be, adding a filter drops this to 70secs). 2pints/min mean > 200bhp so plenty of fuel.

[End of update]

Strange days indeed (nice weather for a drive though).

Matt

p.s. Spyder, thanks for that idea I will look into it. Both my filters are transparent and at idle I haven't seen bubbles, but who knows what

happens at full chat.

p.p.s. Tony, good thought. The A34 near me sounds ideal for this, although it is never quiet. I need to sort out the rear suspension as at the

moment above 90mph requires more than one lane (of the private road) as it is a bit twitchy.

[Edited on 27/7/09 by matt_gsxr]

matt_gsxr - 27/7/09 at 10:44 PM

Looks like it is probably my choice of main jets and needle positions (as Geoff pointed out very early in this chain of postings, sorry Geoff).

I will pretend that it might have been the fuel flow aswell, but looking at the logs the evidence is weak.

Matt

matt_gsxr - 11/9/09 at 10:34 PM

Just as a follow-up. Don't you hate it when you do a search, the thread gets interesting, and then it dies.

Anyway.

It turned out that the O2 sensor was buggered, so the high O2 peaks were erroneous. I got a new sensor (£47 and that was from the USA) and it all

reads properly.

Also after I changed to the later pump, which was providing more volume this seemed to overpower the float valve on cylinder 1. I had already bebuilt

these and the parts were a pain to find, so I was bored of carbs. Especially as the ones that I had were non-standard (ex-sidecar racer).

So, I accelerated "plan B", which was to fuel inject the car. To cut a long story short, it is great. No fuel smell, good starting, and I

can mess around with it without having to buy £100 jetting kits that don't work. Infinite twiddling but using a keyboard instead of burning my

fingers trying to adjust the idle adjusters (especially on cylinder 3). 15 year old carbs are not much fun.

Fuel injection is the future (I know this isn't new information) but I am a slow learner.

Matt