Rescued attachment freestyle shift.gif

Guys,

My plan is to use a Mini engine and tranny in a middy layout. Anybody ever built anything similar? Ifso how was the gear shift operated?

I know it's been done a lot - Terrapin, Landar, Cox GTM, Freestyle, NCF Blitz, etc. So it can't be too hard.

Cheers,

Gareth

Gareth, have you studied the Terrapin gear change? It's quite complex, although it must work I guess.

I'd think I'd look at cables personally. I've done rod changes and play and inertia are big isssues.

why dont you try to find a newer engine with current emmission standards and unleaded fuel. definately try morse cables not pushrods unless you aim to fit the engine without rubber mounts.

quote:

Originally posted by gholman

why dont you try to find a newer engine with current emmission standards and unleaded fuel. definately try morse cables not pushrods unless you aim to fit the engine without rubber mounts.

I'd like to have a look at the freestyle gearchange, any chance of you posting a piccy?

John

quote:

Originally posted by interestedparty

I'd like to have a look at the freestyle gearchange, any chance of you posting a piccy?

John

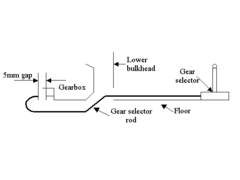

Yes, it's about what I thought it would be, in essence the gear selector output rod and the gearbox input are in line,trouble is the gearbox is in the

way, so the selector rod is cranked down under the gearbox. I'll have a look at doint that on mine, even though the gearbox input is over to the left

of the car, might still work

Thanks

John

I havent worked on a BMC for ages (thankyou Lord!) but...didnt the Austin Kimberley and Tasman have a morse cable linkage from the gearstick, maybe

you could match them up with a longer cable if the linkages dont work. My Kimberelywas bored out the fit Australian Holden pistons (pommy stuff too

expensive!) but with all the engine mods and additional torsion bar it would beat the 6cyl x-flow cortina's. Triple Su's helped and a straight through

exhaust with headers, double clutch plates and landrover master and slave clutch cylinders.

Cheers from Bunbury, West Australia.

My car will use a Corolla FWD box mounted in the back and I intend to use as much of the Corolla gearshift mechanism as possible. Toyota uses a pair

of cables, one of which rotates the selector shaft through a simple crank-arm. The other moves the shaft in-and-out with a bell-crank type of deal.

If it would help anyone, I can probably post some pics of the gearbox with cables attached as well as some scans from the relevant workshop manual

pages showing the relationship of all the bits. So it may be possible to pull the gearshift from a Corolla and modify it for the Mini box.

Hope this helps,

Dominic

quote:

Originally posted by TheGecko

If it would help anyone, I can probably post some pics of the gearbox with cables attached as well as some scans from the relevant workshop manual pages showing the relationship of all the bits. So it may be possible to pull the gearshift from a Corolla and modify it for the Mini box.

quote:

Originally posted by interestedparty

It would help me, yes please

Excellent pics, thanks, Dominic. I think I've got it. If I understand the motions correctly then the upper cable in the first picture is the nearest

cable in the second picture, in that it transfers side to side motion of the gearleer into rotary motion at the selector shaft

I now need to consider the reverse detent mechanism (built into the Ford rod remote on my donor.) I might try machining a Ferarri style gate for the

gearlever, and build a reverse-guard into that

Thanks

John

Dominic,

Thanks for that. I can see how that might be adapted to a Mini shift quite easilly. I should be able to put something togerther based on the mini

remote housing. The only trick would be finding suitable cables, anybody know of a rear engined car with a cable linkage gearchange. Or maybe I could

use clutch cables from a rear engined car.

The other alternative is something an AA man once used on my old Renault 5. The clutch cable went (as they do) and he used a temporary cable.

Basically, IIRC this was a cable that he cut to length and then attached clamp on nipple ends to suit. It all came in a kit. Anybody know where I

could get such a kit and how much it would cost? Sounds ideal for the job if it doesn't cost too much.

Gareth

quote:

Originally posted by interestedparty

If I understand the motions correctly then the upper cable in the first picture is the nearest cable in the second picture, in that it transfers side to side motion of the gearleer into rotary motion at the selector shaft

I now need to consider the reverse detent mechanism (built into the Ford rod remote on my donor.) I might try machining a Ferarri style gate for the gearlever, and build a reverse-guard into that

quote:

Originally posted by garethpowys

The only trick would be finding suitable cables, anybody know of a rear engined car with a cable linkage gearchange. Or maybe I could use clutch cables from a rear engined car.

You may also want to see the MR2 version of the shift bracket.

click here for MR2 gearchange

quote:

Originally posted by Alan B

You may also want to see the MR2 version of the shift bracket.

Cable links:

http://www.controlcables.com/cables.htm

http://www.hersinc.net/Push-Pull%20cables.htm

http://www.uflexusa.com/

Ok, all US, but Dominic is right they are readily available...I think Morse and Teleflex are the most wel known.

After that it isn't much more difficult than than a regular gearchange extension.

Alan, what is all that brownish/red stuff on your gearchange? Did somone spill something on it?

Thanks for the pic BTW, I guess the other end is similar to Dominic's?

John

Just plain old rust John!

No plating on the part....maybe someone spilled a drink sometime?

Yes the other end is very similar to Domincs pic. I'll post something when I can find a good pic.

Ok this is it.

re clutch cables i know peeps who "work" for aa and rac,mail me with what you want and i can post you some.

Hi all,

Further to the discussion on this topic back in November - I've just come across a nicely detailed set of photos and drawings for a scratch built

shift linkage - Link. In this case, it's for an Audi 5000

'box in a Lambo replica but the principle is the same: two cables and a linkage that gives both rotary and in-out motion to the selector shaft on the

box.

For what it's worth.

Dominic