HELP! Is my engine knackered?

Gremlin - 25/11/03 at 01:34 AM

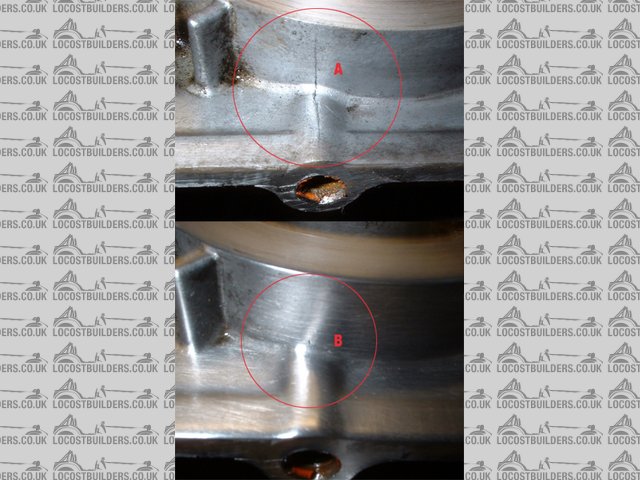

I have a R1 engine and was taking the sump of to add an oil baffle and noticed what looked like a crack (Pic A) when I took out one of the sump bolts.

After closer inspection I was unsure as the alloy case seems to have a few marks over it so I attacked it with a bit of wire wool (Pic B).

Looking at (Pic B) it would appear there is no crack but just a surface mark. Having said that, if the crack went all the way through and I attacked

it with wire wool would I have hidden the crack or would it still be visible?

Is it something to still worry about or in your opinions do you think it looks fine and was only a mark?

Thanks in advance a worried builder!

Rescued attachment help.jpg

Metal Hippy - 25/11/03 at 01:39 AM

I can't comment from a particularly stable engineering viewpoint but I would personally say not to worry. If the engine falls apart once

it's up and running in the car then maybe think about using a different one.

I'd guess it's unlikely though if you've managed to polish it out that much.

As I said it may not be sound engineering advice, but hopefully it'll at least prevent you worrying too much about something that may not be that

bad...

Hugh Paterson - 25/11/03 at 02:15 AM

Would not worry too much, if it is a crack it can be tig welded whats it look like inside the casting?

whats it look like inside the casting?

Shug.

Gremlin - 25/11/03 at 10:21 AM

Thanks for your comments. Anyone have any thoughts?

Rescued attachment inside.jpg

ned - 25/11/03 at 11:13 AM

Gremlin,

Why not wander up to a few bikes at your local car/bike park or station and have a quick look (without looking too sinister or criminal) I'd bet

that most of the engines there don't look spotless....

Ned.

[Edited on 25/11/03 by ned]

James - 25/11/03 at 11:51 AM

You could try pouring something penetrative (but evaporative) inside that area and see if anything leaks out I guess.

I say evaporative coz you don't want to leave anything in your block that may affect the oil!

You could also post this on the Yahoo Bike Engined Cars forum if you haven't already. I gather there's some pretty experienced BECers

there.

HTH,

James

Lightning - 25/11/03 at 12:05 PM

Get Dye penetrant from an engineering supplies. It will highlight if there is a crack

DaveFJ - 25/11/03 at 01:21 PM

best way to be sure is to obtain a crack detection dye penetrant kit as Lightning suggests. However i do not know how easy these are to get hold of or

how much they cost for the 'home user'.

With soft alloys 'polishing' the area like you have done will usually disguise any cracks so they become much harder to detect. - sorry

Another usefull tool is an optical depth guage, basically this is a small hand held microscope which engineers use to judge the depth of scratches etc

by adjusting the calibrated focus..... however it is also incredibly useful for getting a really close look at anything suspicious. I have discovered

many potentially life threatning (on aircraft) cracks in this manner.....

Having said all that I would be surprised, based on picture1, if you do have a crack. The postion, direction, length and apperance are a little

unlikely - from my experience.

HTH

Dave

Gremlin - 25/11/03 at 08:18 PM

Had a couple of people around today and it looks like i was worrying about nothing looks as though it was just a surface blemish.

Just freaky it was inline with a thread but there seems to be other similar marks else where and a little wire wool and a recheck and all is fine.

Thanks for the thoughts.

Browser - 26/11/03 at 02:23 AM

Gremlin, was it a squigly line of alloy standing proud of the surrounding metal? Looking at photo 1 it looks more like casting flash than a crack and,

if so, is nothing to worry about.

David Jenkins - 26/11/03 at 08:45 AM

Just a slightly gloomy thought - is whatever screws into that hole a tapered thread (like a sump plug, or similar)?

If so, you may want to screw it in before looking for cracks... someone may have over-tightened it in the past.

Hoping I'm very wrong,

David

Gremlin - 26/11/03 at 10:32 AM

It didnít stand proud but only looked to be a few hundreds of a mm deep and just in the surface layer as if it were a crack in a think layer of paint

hence why I attacked it with wire wool.

The bolt that goes into the hole is just a sump pan bolt which is tightened to 10nm and the bit of cast that is visible I have noticed that even if it

were to be a cracked would not actually go through to the inside of the oil sump but just into the bolts thread as the other side of the bolt thread

is the side that keeps the oil in.

If that makes sense?

Having said that I did put the bolt back in as tight as I could without doing any more damage to see if a crack appeared and it looked fine.

I did spend quite some time last night covering it in ink, old oil, charcoal and tipex to see if when I rubbed it of some would be still stuck in a

crack to make it stand out but it never happened so I think it was a surface blemish as I have found a few marks similar else where on the engine and

if it had been a crack I think it would have started at this end of the thread and not the other.

[Edited on 26/11/03 by Gremlin]

garage19 - 26/11/03 at 01:28 PM

I have rebuilt a few blade engines and seen bits like this before. They are usaully just marks from the casting process.

Hellfire - 26/11/03 at 10:00 PM

...seems to be a casting flaw. During my visits to numerous alloy block manufacturer's in the UK - this normally happens when the molten

aluminium 'chills' a little sooner than anticipated casing a wrinkle in the skin... normally nothing to worry about. Especially if is

polishes out. I wouldn't worry about it - but if you are have a line MIG/TIG'd on for your peace of mind -

whats it look like inside the casting?

whats it look like inside the casting?