Electric Reverse Trike

ro - 18/11/15 at 08:47 PM

Hi, I'm Ro and I'm based in the New Forest

I've been wanting to build a kit car for years and years, but currently having 4 cars, none of which I can bear to part with, I thought I'd

build something smaller.

I've always been interested in electric vehicles and when I saw the MEV Etrike I got hooked on

the idea of a small electric reverse trike.

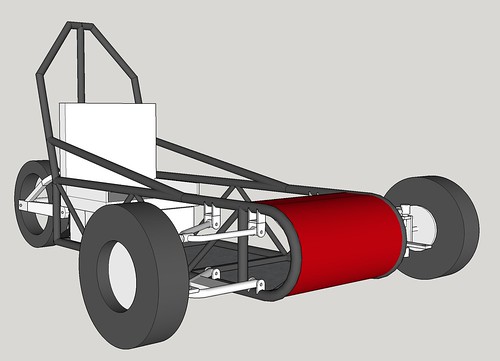

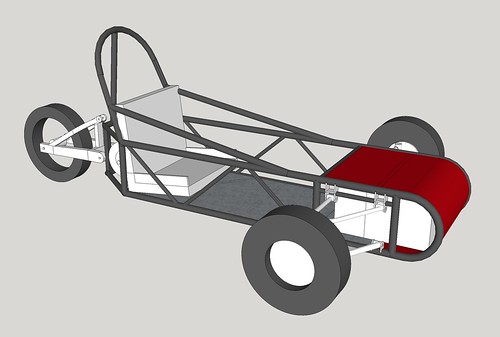

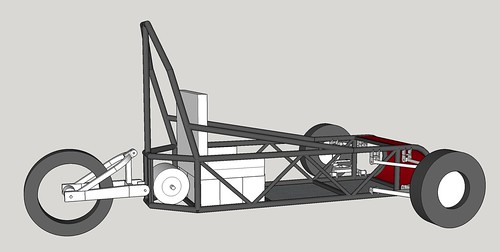

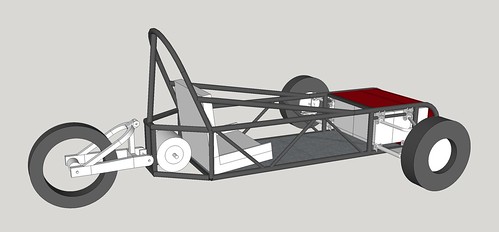

I've made a couple of changes to the design of the Etrike chassis and ended up with something that looks like this:

Main chassis tubing is 1 1/4 inch mild steel. I have acquired the front suspension off an old quad and the swingarm from a pitbike. The motor Is a

Motenergy ME1003 which should produce 30hp peak. Batteries are located under the seat.

Obviously I still have to add the shocks and steering but any feedback at this stage would be appreciated!

Thanks for looking

ro

twybrow - 18/11/15 at 09:52 PM

I love the idea - hats off for the leftfield approach. One question, why not make the roll hoop a single piece with a bend?

v8kid - 19/11/15 at 07:15 AM

IIRC thekey to reverse trikes is to get the weight as far forward as possible so shove the batteries between the front wheels. There are a number of

papers on the subject that should be available on Google

Cheers

Just remembered mark Ortiz and it was Aug 2015 newsletter

[Edited on 19-11-15 by v8kid]

[Edited on 19-11-15 by v8kid]

[Edited on 19-11-15 by v8kid]

russbost - 19/11/15 at 11:01 AM

The Motenergy ME1003 is 20Kw peak, 11.5max continuous at 72V

To run at that continuous power (which is probably way more than you need) you'd be pulling 140amps from your batteries - you're either

going to need a lot more batteries than your pic shows (remember you'll need 6 x 12V to get to 72V before putting any in parallel to extend

endurance) or you'd need to run at much lower power.

As already said the batteries need to be placed at the forward end towards/between the front wheels for stability, tho' with the weight that low

should be reasonably stable anyway

I can't remember what Stig used for the Etrike, but don't think it was that powerful, a kart with two 6.5Hp engines, ie 13Hp can make speeds

of over 70mph & 0 - 60 in around 5 secs I think, with 20Kw peak you'd have double that power in probably around double the weight so similar

acceleration, but way higher top speed, it wouldn't maintain it for long at that power usage tho'

ro - 19/11/15 at 01:10 PM

Wow, thanks for the responses!

quote:

Originally posted by twybrow

I love the idea - hats off for the leftfield approach. One question, why not make the roll hoop a single piece with a bend?

Good question! I'll update the design tonight and see what it looks like.

quote:

Originally posted by v8kid

IIRC thekey to reverse trikes is to get the weight as far forward as possible so shove the batteries between the front wheels. There are a number of

papers on the subject that should be available on Google

quote:

Originally posted by russbost

As already said the batteries need to be placed at the forward end towards/between the front wheels for stability, tho' with the weight that low

should be reasonably stable anyway

OK, I naively assumed that more weight near the rear wheel would improve traction, but after a good google of the subject I can see you both are

correct. Can you see any problems with putting the batteries forward of the front axle line, or do they have to go directly between/just behing the

axle line?

quote:

Originally posted by russbost

To run at that continuous power (which is probably way more than you need) you'd be pulling 140amps from your batteries - you're either

going to need a lot more batteries than your pic shows (remember you'll need 6 x 12V to get to 72V before putting any in parallel to extend

endurance) or you'd need to run at much lower power.

I was planning to use 6 YC33 batteries in series to give me 72V.

I'm hoping that most of the time I would not be drawing anywhere near 140 amps, only occasionally using higher powers for spurts of acceleration.

Would these batteries be able to deliver short bursts of 140amps?

quote:

Originally posted by russbost

I can't remember what Stig used for the Etrike, but don't think it was that powerful, a kart with two 6.5Hp engines, ie 13Hp can make speeds

of over 70mph & 0 - 60 in around 5 secs I think, with 20Kw peak you'd have double that power in probably around double the weight so similar

acceleration, but way higher top speed, it wouldn't maintain it for long at that power usage tho'

Stig recommends the Perm PMG 132 for the Etrike, which appears to be impossible to

obtain for a decent price. I was hoping that the ME1003 would be a decent replacement. Do you think it's overkill and I should really be looking

at something smaller like the ME0708, or should I just find somewhere to stash more batteries and go for it?

smart51 - 19/11/15 at 05:11 PM

I learned the hard way. A trike chassis needs to be stiff in torsion. Put a good X brace in the floor of the chassis.

You want the weight as low as possible. Don't put the batteries under the seat. Fit the seat as low as you can.

You also want the weight to be towards the front. If you want to do the calcs, this is what you want to aim for. Take the worst case scenario - the

car going down a 1 in 3 hill with the brakes stopping you at 1.5g with the rear wheel going over a bump. Draw a line from the centre of gravity that

is the sum of gravity and deceleration and the bump force. It MUST touch the ground behind the line of the front axle. Not difficult to calculate

but quite involved.

In short, put the heavy stuff at the front.

At at steady urban speeds, you might draw 6kW from the batteries - around 80A. On a dual carriageway, you might pull 30kW out of the batteries - well

over 400A. You'll need a really thick cable!

[Edited on 19-11-2015 by smart51]

russbost - 19/11/15 at 06:09 PM

"OK, I naively assumed that more weight near the rear wheel would improve traction, but after a good google of the subject I can see you both are

correct. Can you see any problems with putting the batteries forward of the front axle line, or do they have to go directly between/just behing the

axle line?"

If you put the batteries forward of the front axle line you could easily finish up standing it on its nose under braking you need to do the calcs

Smart51 suggests

"I was planning to use 6 YC33 batteries in series to give me

72V.

I'm hoping that most of the time I would not be drawing anywhere near 140 amps, only occasionally using higher powers for spurts of acceleration.

Would these batteries be able to deliver short bursts of 140amps?"

They don't seem to give a max current spec, but I would think 140A would be no problem for short bursts, but @35Ah those batteries as a pack of 6

aren't going to last long or get you very far - downhill & on the flat is no problem, but put a few decent uphill stretches in the way where

you might be pulling 200A or more & you'll be coming to a grinding halt fairly rapidly, also remember that even with traction batteries they

recommend that you don't regularly discharge below 50% so that 35Ah just became 17Ah!!

" I was hoping that the ME1003 would be a decent replacement. Do you think it's overkill and I should really be looking at something smaller

like the ME0708, or should I just find somewhere to stash more batteries and go for it?"

Depends entirely what you are trying to achieve & what you want the trike to do, if you want dragster like acceleration then you want the biggest

motor you can get, if you want endurance the smallest etc etc If it's for a regular commute or regular local journeys where you can top up the

batteries regularly then you have a whole different ball game to if you're planning on taking it on a touring holiday! I would have thought for a

lightweight vehicle the ME0708 would be adequate, remember that electric motors have all their torque available pretty much all the time, not just at

a certain rev band. Re stashing more batteries, a lot depends on your budget!

I would suggest join batteryvehiclesociety.org.uk & have a chat with the guys over there, they are the gurus for this sort of stuff, I have only

dabbled & have my basic A level physics & HND in engineering for info, but most of it is common sense, you just need to do a few sums to check

what's feasible

smart51 - 19/11/15 at 06:32 PM

quote:

Originally posted by russbost

If you put the batteries forward of the front axle line you could easily finish up standing it on its nose under braking you need to do the calcs

Smart51 suggests

I wouldn't worry too much about it. You have 75kg of driver and 100kg of trike behind the rear axle. Some of it a fair way behind. You can put

a lot of battery just ahead of the front axle and still be OK.

My trike weighed 75kg on each front wheel and 85kg at the back. I never came close to lifting the back wheel. That said, the seat of my pants was

170mm from the ground.

ro - 19/11/15 at 09:47 PM

Thanks for all the feedback. I'm reworking the design to try to take it all into account, but it's taking a while. I'll post the

changes as soon as I have them.

On the motor front, would it be worth going for a 48v system and 8 x 12v batteries instead of 72v with 6? Or will the larger current draw empty the

batteries sooner?

Thanks again to everyone for the help!

russbost - 20/11/15 at 09:25 AM

"On the motor front, would it be worth going for a 48v system and 8 x 12v batteries instead of 72v with 6? Or will the larger current draw empty

the batteries sooner?"

It will depend on the overall current draw of the motor vs the storage capacity of the batteries, as a very rough general rule if you're using a

lower power motor (ignore voltage, look at Kw or HP) & more batteries of similar capacity you're going to have less performance & more

range

ro - 21/11/15 at 06:09 PM

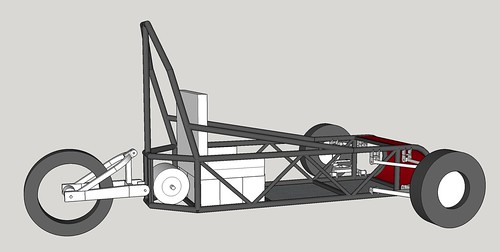

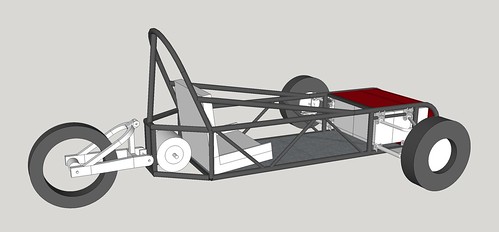

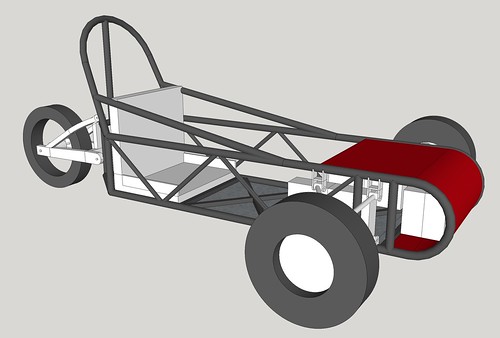

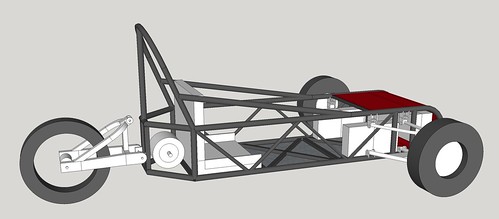

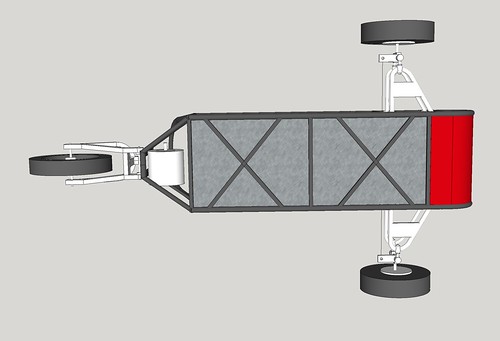

Right, Ive made some changes to the design based on the help you guys have given me (Thanks!)

The motor has been changed to a LEM170 allowing me to have 2 banks of 4 batteries (and the capacity to add 2 more banks if I need to) which should

give me about 1/2 an hour run time.

The batteries have been moved over the front wheels to move the centre of gravity forward, and with my bulk towards the rear I don't think

there's much chance of it standing on its nose!

The lowering of the seat has allowed me to lower the roll hoop and I've changed it to a single radius to match the front. Oh, and I've added

some X bracing to the floor.

What do you think?

v8kid - 21/11/15 at 06:32 PM

I guess you are going to use a toothed belt or chain drive direct to the rear wheel without a gearbox?

In which case you can offset the motor and have the motor spindle co-axially aligned with the swinging arm front bearing that way the belt/chain

tension will be constant rather than slacking under acceleration.

Handily that will free up some space on the side opposed to the motor and you could install a small 2 stroke 800W generator constantly charging the

batteries. As battery capacity (in Ahr) increases as the discharge current (A) gets less you get a double whammy of either increased range or power

for the same range.

I would have some sort of bulkhead between the batteries and my body. Acid burns!

An alternative is to have two motors one driving each front wheel as the characteristics of electric motors gives an automatic differential effect.

Not sure why you want to reduce the voltage! Higher voltages are more efficient and the control gear is lighter and cheaper due to the lower currents.

If its down to the size of batteries available remember as you double the voltage you halve the Ahr capacity required.

Cheers!

blakep82 - 21/11/15 at 07:45 PM

Along with that roll hoop, I would perhaps have another look at the top wishbone mounts too, look like a little leverage would have them ripped off

the tube with the length of them?

Looking good tho

Volvorsport - 21/11/15 at 08:50 PM

Fwd is the way forward on safe handling trikes....

gremlin1234 - 21/11/15 at 08:56 PM

some interesting ideas here.

but what motor controller might you use?

ok I haven't built any electric cars (yet), but I thought if you used a pwm controller (pulse width modulation) you can / should feed it with a

higher voltage than the apparent output voltage.

so could you not use the "Motenergy ME1003" and 8 12v batteries (~96v) and feed them into a controller like this:

200A 24-100V 24V 48V 60V 72V current limited DC motor PWM speed controller

eBay Item

ps that power controller seems to accept sister units to double its capacity too.

[Edited on 21/11/15 by gremlin1234]

Sam_68 - 21/11/15 at 09:12 PM

Gotta agree with Volvorsport on FWD being the better way for safe handling on a trike, though there are plenty of RWD trikes out there with much

higher power:weight ratios than you'll have, and they do just fine when driven sensibly.

These threads on Martinslyon's similar electric trike project might be of interest:

http://www.locostbuilders.co.uk/forum/27/viewthread.php?tid=172100&page=1

http://www.pistonheads.com/gassing/topic.asp?h=0&t=969988&d=11985.23157&nmt=

I don't know how far he got with it - it seemed to go quiet - but notwithstanding a few caveats about battery location and monoshock design, it

seemed like a promising idea.

ro - 21/11/15 at 09:47 PM

quote:

Originally posted by v8kid

I guess you are going to use a toothed belt or chain drive direct to the rear wheel without a gearbox? In which case you can offset the motor and have

the motor spindle co-axially aligned with the swinging arm front bearing that way the belt/chain tension will be constant rather than slacking under

acceleration.

Oh! I hadn't thought of that. That is frickin' genius. Let me see if I can work that into the design. Thank you!

quote:

Originally posted by v8kid

Handily that will free up some space on the side opposed to the motor and you could install a small 2 stroke 800W generator constantly charging the

batteries.

That's another great idea, but I think I'll leave thinking about that until after I have got this roadworthy.

quote:

Originally posted by v8kid

I would have some sort of bulkhead between the batteries and my body. Acid burns!

Yep, I'm planning on putting sheet metal between them and me, and creating a subframe to hold them, but I have been too lazy to design that up

while the other parts of the design are changing all the time.

quote:

Originally posted by blakep82

Along with that roll hoop, I would perhaps have another look at the top wishbone mounts too, look like a little leverage would have them ripped off

the tube with the length of them? Looking good tho

Thanks  You're right they need bracing. I'll add that in V3 (hopefully posted in the next couple of days).

You're right they need bracing. I'll add that in V3 (hopefully posted in the next couple of days).

quote:

Originally posted by gremlin1234

...but I thought if you used a pwm controller (pulse width modulation) you can / should feed it with a higher voltage than the apparent output

voltage.

so could you not use the "Motenergy ME1003" and 8 12v batteries (~96v) and feed them into a controller

I was planning on using an

AXE7234 or similar, as it has programmable settings for throttle response, max current etc; but I have been wondering about using a simple PWM

controller or even hooking the PWM output of an AVR microcontroller up to some big power transistors. At that price it could be worth buying one first

just to see if it's any good...

One question that I can't seem to get my head around:

Let's assume that I want 50V output @ 100A (for the sake of easy maths) for as long as possible.

Would I be better supplying a PWM controller with

1) 100V from 10x10V batteries in series (10S)

2) 50v from 2 sets of 5x10v batteries in parallel (5S2P)

I can't see that there would be any difference between them, apart from lower transmission losses in scenario 1. Am I wrong?

And, yes I know. FWD would be better, but I really, really want to see what oversteer is like in a trike! Oh, and I'm sure that this one will be

driven sensibly. Occasionally.

v8kid - 22/11/15 at 09:13 AM

Lots of people have tried and never really succeeded so you can't look to tried methods - after all its pointless copying failure!

The issue is the weight and limited capacity of the batteries. So why not dump the big batteries?

Super capacitors are light with very good discharge rates but do not hold a huge charge. They would do for acceleration power but run out of steam for

cruising. Add a lightweight generator for cruising.

There may be a balance to be met between the size of generator and the cruising speed in which case you could have a smaller generator coupled with

motorcycle batteries which gives a higher cruising speed.

The project could be completed in stages with a bit of smart planning at the beginning.

Could be a long project though 😁

Cheers!

smart51 - 22/11/15 at 10:36 AM

If you're concerned about weight and range, a generator is the way to go. An ordinary car might have 100 BHP but you hardly ever use it all.

You might use half of that during brisk but sensible acceleration and about a fifth of that on a level motorway. The best thing to do is have 100 BHP

electric motors and enough battery to supply this for say 15 minutes. Then have a 25 BHP generator supplying the electricity

Sam_68 - 22/11/15 at 11:21 AM

quote:

Originally posted by smart51

If you're concerned about weight and range, a generator is the way to go. An ordinary car might have 100 BHP but you hardly ever use it all.

You might use half of that during brisk but sensible acceleration and about a fifth of that on a level motorway. The best thing to do is have 100 BHP

electric motors and enough battery to supply this for say 15 minutes. Then have a 25 BHP generator supplying the electricity

With range extender hybrids, though, it's a difficult and complicated balancing act to get right in terms of efficiency.

If you're not careful, after the first 15 minutes you effectively end up with a 25bhp IC-engined car, but with its efficiency reduced by 30% for

all the losses incurred converting the IC engine's horsepower to electricity (generator), then to chemical energy (batteries), then back to

electrical energy (batteries), then to horsepower that can be used at the wheels (electric motor).

That's an over-simplification, I know - ignoring factors such as being able to run the IC engine at constant revs and load, optimised for

efficiency - but still not far off reality.

The opposite extreme of the balance is to do what Honda has done with its IMA system; use the IC engine as the prime mover, with an electric motor to

provide the 'boost'.

v8kid - 22/11/15 at 11:30 AM

quote:

The opposite extreme of the balance is to do what Honda has done with its IMA system; use the IC engine as the prime mover, with an electric motor to

provide the 'boost'.

Yup i agree thats the best route but for a simple locost project its too complicated and too heavy. OK for Honda with all its resources.

Gearboxes are heavy and have to be included in the packaging its bad enough with batteries!

If the project can minimize the weight it would be a great fun machine to play with - after all the OP is not trying to produce a viable alternative

to a mass market tin top - at least I presume not

Cheers!

ro - 22/11/15 at 12:14 PM

quote:

Originally posted by v8kid

If the project can minimize the weight it would be a great fun machine to play with - after all the OP is not trying to produce a viable alternative

to a mass market tin top - at least I presume not

Yup, the point of this project is to have a small, lightweight, low cost, fun little machine with a range of about 20 miles. Enough range & power

to blast around country roads and maybe stop off at a pub along the way!

I think that adding a genny at this point would overcomplicate what is supposed to be a simple little trike. Although at some point in the

future...

I'm still dithering over battery sizes. I've been convinced by the replies on this thread, and by loads of reading on the web that 72V is

preferable to 48V and that 6x33ah batteries probably aren't enough to give me my desired range.

I'm now looking at using 6x55ah SLA batteries. The trouble is that these take up a lot more room, so putting them all in between the front wheels

would make for a massively long body. Current thinking is to put 2 between the front wheels and then 2 down each side of the body, behind the front

wheels and outside of the main body to allow lots of legroom inside. 3d sketches to follow soon...

Volvorsport - 22/11/15 at 12:36 PM

Is there not a battery pack that comes from a hybrid that you can use already?

ettore bugatti - 22/11/15 at 12:37 PM

Interesting project.

Keeping it simple must be the way forward.

I guess getting an affordable drive train (motor batteries) is the main challenge.

http://www.evalbum.com/ is a good site to get some ideas.

smart51 - 22/11/15 at 02:44 PM

quote:

Originally posted by Sam_68

quote:

Originally posted by smart51

If you're concerned about weight and range, a generator is the way to go. An ordinary car might have 100 BHP but you hardly ever use it all.

You might use half of that during brisk but sensible acceleration and about a fifth of that on a level motorway. The best thing to do is have 100 BHP

electric motors and enough battery to supply this for say 15 minutes. Then have a 25 BHP generator supplying the electricity

With range extender hybrids, though, it's a difficult and complicated balancing act to get right in terms of efficiency.

If you're not careful, after the first 15 minutes you effectively end up with a 25bhp IC-engined car, but with its efficiency reduced by 30% for

all the losses incurred converting the IC engine's horsepower to electricity (generator), then to chemical energy (batteries), then back to

electrical energy (batteries), then to horsepower that can be used at the wheels (electric motor).

That's an over-simplification, I know - ignoring factors such as being able to run the IC engine at constant revs and load, optimised for

efficiency - but still not far off reality.

The opposite extreme of the balance is to do what Honda has done with its IMA system; use the IC engine as the prime mover, with an electric motor to

provide the 'boost'.

In my example the engine will be on most of the time. The battery will supply the extra power for acceleration and hill climbing, with the surplus

power from the generator charging the battery the rest of the time.

Sam_68 - 22/11/15 at 03:47 PM

quote:

Originally posted by smart51

In my example the engine will be on most of the time. The battery will supply the extra power for acceleration and hill climbing, with the surplus

power from the generator charging the battery the rest of the time.

Then you'd probably be better off with the IC engine driving the wheels directly, with the electric motor to assist it (Integrated Motor Assist -

the Honda approach), rather than acting as a generator.

Every time you force energy to change form there is a percentage loss in efficiency, so it doesn't usually make sense to make your primary source

of power change its form many times on its way to the wheels (chemical>heat>mechanical>electrical>chemical>electrical>mechanical in

your example).

That's why operating regime is so crucial to how effective different forms of hybrids are: Range Extender PHEVs are at their best when most of

their journeys are short enough to be pure electric (city or local driving), whereas IMA works best on longer/faster motorway and open road

driving.

Get the balance wrong, and one half of your hybrid powertrain is little more than dead weight.

smart51 - 22/11/15 at 06:25 PM

quote:

Originally posted by Sam_68

quote:

Originally posted by smart51

In my example the engine will be on most of the time. The battery will supply the extra power for acceleration and hill climbing, with the surplus

power from the generator charging the battery the rest of the time.

Then you'd probably be better off with the IC engine driving the wheels directly, with the electric motor to assist it (Integrated Motor Assist -

the Honda approach), rather than acting as a generator.

Every time you force energy to change form there is a percentage loss in efficiency, so it doesn't usually make sense to make your primary source

of power change its form many times on its way to the wheels (chemical>heat>mechanical>electrical>chemical>electrical>mechanical in

your example).

That's why operating regime is so crucial to how effective different forms of hybrids are: Range Extender PHEVs are at their best when most of

their journeys are short enough to be pure electric (city or local driving), whereas IMA works best on longer/faster motorway and open road

driving.

Get the balance wrong, and one half of your hybrid powertrain is little more than dead weight.

Decent generators, motors and drive electronics are similarly efficient to a gearbox, differential and drive shafts. The advantages of electric drive

are that the engine is always operating at its most efficient point, and that it can be turned off when stationary or when the batteries are fully

charged. You get regen braking too.

ro - 22/11/15 at 06:32 PM

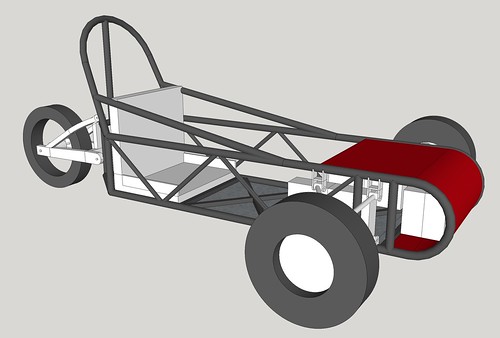

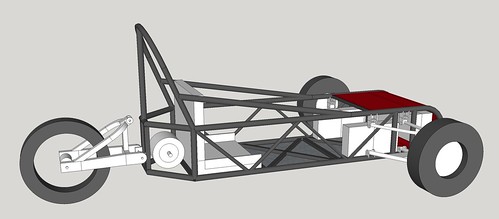

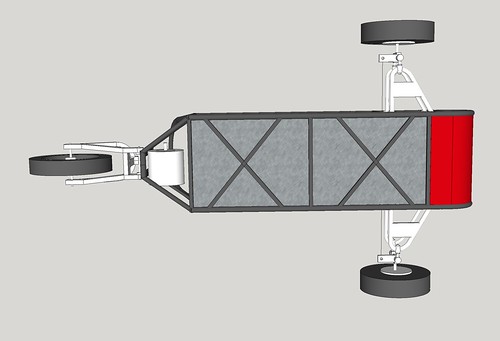

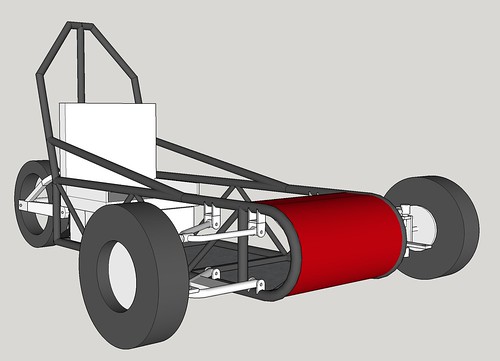

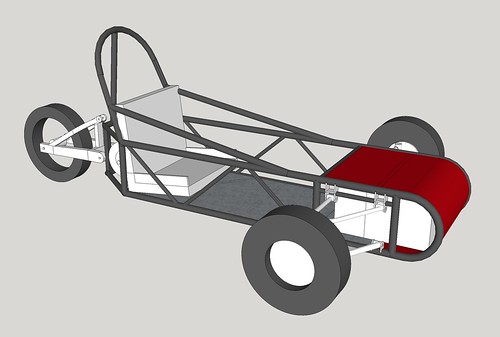

OK, after trying lots of designs, I have given up on the idea of widening the body and putting the batteries down the side. I just could not make it

look any good

I think I've now virtually nailed the design. 6x55ah batteries up front. Wishbones and steering reversed to make extra room for the batteries.

Seat canted to allow a "legs bent" driving position gives me more room at the front.

I've also moved the floor above the cross braces and slightly increased the length of the rear section to allow more access to the motor.

Unfortunately I could not find a way of mounting the motor co-axially with the swingarm without drastically increasing the width of the whole trike

quote:

Originally posted by Volvorsport

Is there not a battery pack that comes from a hybrid that you can use already?

quote:

Originally posted by ettore bugattiI guess getting an affordable drive train (motor batteries) is the main challenge.

Yeah, balancing cost, weight, power and range seems to be the main challenge with this project. Unfortunately all existing hybrid batteries seem to be

a) really bloody expensive and b) really high voltage.

quote:

Originally posted by blakep82

Along with that roll hoop, I would perhaps have another look at the top wishbone mounts too, look like a little leverage would have them ripped off

the tube with the length of them?

Do these ones look any better?

Volvorsport - 22/11/15 at 06:53 PM

I've found a certain French small car manufacturer has a subframe where all the bits happily Bolt on

smart51 - 22/11/15 at 06:56 PM

quote:

Unfortunately I could not find a way of mounting the motor co-axially with the swingarm without drastically increasing the width of the whole

trike

How about mounting the motor on the rear swing arm? That way the distance between the motor and rear wheel will never change. Mount the motor over

the pivot point and it will not add much to the unsprung weight. Mount it forward of the pivot point and it will counterbalance the unsprung weight

of the rear wheel.

ro - 22/11/15 at 07:09 PM

quote:

Originally posted by smart51

How about mounting the motor on the rear swing arm...

Nice idea! For now, in the name of keeping it simple before the IVA, I have bought a second hand swing arm and wheel assembly.

However, if I was to fabricate a new swing arm (with motor) after this is on the road, I could use the space that the motor currently takes up to

mount a small generator. Hmmm, I like that idea. I REALLY like that idea! I'll make sure there's enough room back there...

Anyway, I'm trying hard to keep this simple to start with otherwise I may never finish it - I have a bad habit of overcomplicating projects and

not finishing them!

Sam_68 - 22/11/15 at 07:14 PM

quote:

Originally posted by Volvorsport

I've found a certain French small car manufacturer has a subframe where all the bits happily Bolt on

Yes, given the performance/range parameters, you seem to be conceptually quite close to the Twizy. Seems the obvious thing to benchmark against?

I understand that in some Euro markets, they sell the battery pack outright rather than leasing it, too, which might be worth looking into.

Always worth looking for 'proof of the pudding'... the Twizy will show you the best that's realistically achievable with a small

commuter EV, and similarly, the major manufacturers have spent huge amounts researching the optimum solutions for hybrids.

Suffice it to say that I don't know of any major manufacturer that uses a continuously running IC engine as a generator for electric drive;

they're all PHEVs with IC range extenders that only kick in when the battery starts getting depleted, or IC direct drive, supported by electric

(or vice versa).