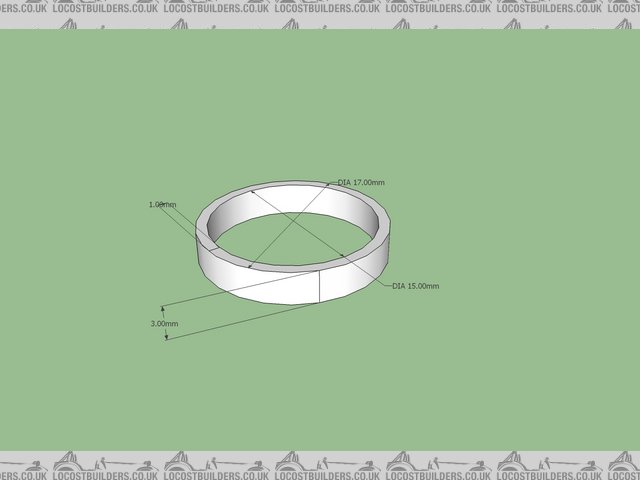

the easiest fix i can see is to put this sort of thing in

Description

its tiny though, too small to be done on a lathe i think... any ideas?

my new denso pulley has a 15mm hole, and the pulley has a 17mm hole

the easiest fix i can see is to put this sort of thing in

Description

its tiny though, too small to be done on a lathe i think... any ideas?

may be a long shot buy try a cycle shop, see if they have any head stem spacers. they may do the job if small enough. carbon, steel and ali i think they do them in.

awesome  halfords? or do i need to be more specialised than them?

halfords? or do i need to be more specialised than them?

i think theres a specialist round here somewhere

just been looking for them on the net, didnt look at the size, these are going to be about 20mm+ at least not 1.5. but what about maybe a sump washer? their are some small nissan ones about, or maybe fibre washers depending on its use?

make one on a lathe - it can be done

[edit]

thinking about it a bit more - is the pulley a press fit job ?

[Edited on 20/4/2011 by mcerd1]

quote:

Originally posted by mcerd1

make one on a lathe - it can be done

[edit]

thinking about it a bit more - is the pulley a press fit job ?

[Edited on 20/4/2011 by mcerd1]

^^ I think I've sent you too many u2u's now :?

have you got a pic ?

cant you open the hole up in the pulley to make the spacer ring bigger.

adam

what altonator is it off?

or if its a steel pulley just weld the hole up and lathe it out again.

adam

quote:

Originally posted by oadamo

or if its a steel pulley just weld the hole up and lathe it out again.

adam

quote:

Originally posted by blakep82

quote:

Originally posted by oadamo

or if its a steel pulley just weld the hole up and lathe it out again.

adam

ooh, i like it. think this may work out well! i'm going to take to someone tomorrow, see what he says before i weld it up!