Welding - Bridging Gap

scootz - 28/9/17 at 06:29 PM

Evening all

I've been cutting round tube to intersect other round tubes at various angles - turns out it's not quite as easy as it would first seem!

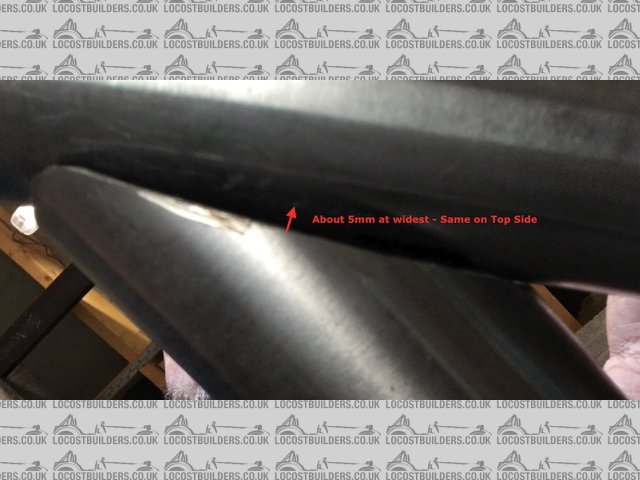

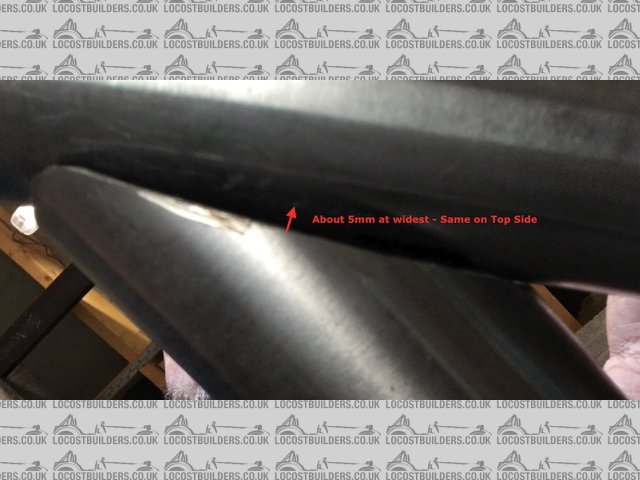

On one chassis member I've found I have a gap on either long side of an intended join. Both less than 5mm at their widest point.

The guy who's doing my welding is a genuine artist - I don't want to dump him with something unworkable.

Can those in the know have a wee look at the pic and let me know if that gap can be bridged and made structurally solid (it's the same on the top

side). Normally I wouldn't;t ask the question as I'd just make another piece until I was happy with the end result, but it's T45 and

it ain't cheap... and only sold in 5 metre lengths!

Cheers

Simon - 28/9/17 at 06:45 PM

That'll weld up just fine, but it'd be better if it wasn't there  Can you trim the long ends of the oval to close the gap a bit?

Can you trim the long ends of the oval to close the gap a bit?

SPYDER - 28/9/17 at 07:00 PM

Your tame welder will moan about it then just weld it no problem.

I had similar issues on our rollcage. The odd gap here and there.

Moan moan weld. Moan moan weld.

Bigheppy - 28/9/17 at 07:04 PM

Have a look at this I found it on mig welding forum

http://dogfeatherdesign.com/ttn_js/

madteg - 28/9/17 at 07:06 PM

Penetration guaranteed

scootz - 28/9/17 at 07:32 PM

Cheers guys

scootz - 28/9/17 at 07:39 PM

quote:

Originally posted by Simon

That'll weld up just fine, but it'd be better if it wasn't there  Can you trim the long ends of the oval to close the gap a bit?

Can you trim the long ends of the oval to close the gap a bit?

That's the danger - I'm down to within 1cm of my minimal length of the tube as I've been fettling for so long! I reckon I can.

probably het the gaps down to 3mm with another wee blast with my grinder.

Speaking of which - my Makita grinder that has served me so well in destroying so many things over the last 8 years died today. RIP. Gone for a

Black and Decker this time.

mark chandler - 28/9/17 at 08:34 PM

It will weld but....

You are getting a lot of heat in there, I bet if once done you hold a straight edge against the bit your welding against it will be buckled.... Been

there, done that and thrown it away in disgust.

[Edited on 28/9/17 by mark chandler]

scootz - 28/9/17 at 08:57 PM

Not too fussed about how the joint looks - just need it to be strong.

loggyboy - 28/9/17 at 08:58 PM

Can you not just remove a little more material to bring the join closer? Shouldn't make more than a few mm to its location/angle.

scootz - 28/9/17 at 09:21 PM

I probably can Loggy... it's just that I'm getting tight on the overall length of the piece, so there's a danger that if I shave off

too much, then both sections as for the bin. I've since spoken with a pal who is a hands-on engineer. He reckons that there's now't

to worry about as there will be plenty penetration on both sides.

ianhurley20 - 28/9/17 at 09:52 PM

For future joins there is a program called tubemiter on google where you specify angles and diameters and it gives you a printout which wrapped around

the tube will ensure a perfect join

907 - 29/9/17 at 05:30 AM

As Mark says in post 8, distortion is your enemy.

When you MIG or TIG a gap that gap will close, and consequently the joint will shrink.

That shrinkage has to go somewhere.

With welding, quality work starts with quality prep.

Paul G

(pro welder)

scootz - 29/9/17 at 08:30 AM

Would heat treating the finished product help in strengthening the joint?

SPYDER - 29/9/17 at 10:22 AM

quote:

Originally posted by 907

When you MIG or TIG a gap that gap will close, and consequently the joint will shrink.

That shrinkage has to go somewhere.

It might not be the proper solution but you could knock a couple of slim wedges in and weld between them. Then pull the wedges out and complete.

It could still shrink but not as much.

ken555 - 29/9/17 at 12:18 PM

Could you not weld some more materials to the end, then reshape it , then weld to the other tube ?

Theshed - 29/9/17 at 05:04 PM

The reply above just beat me to it. It is a doddle. Weld around the edge of the tube, shape off and then weld the two together. I did exactly the same

despite having measured twice and cut....more than that

Description

SPYDER - 29/9/17 at 07:10 PM

^^^^^^^^^ Hi there! How's the build going?

scootz - 29/9/17 at 07:51 PM

I'm liking your style gents. I've plenty T45 left, so I can cut fillets or overlapping pieces. I'd actually thought about doing that

in a few area's which are load-bearing anyway. Belt and braces!

It really is a pest shaping round tube to intersect another piece if round tube.

90 degree angle joins are a doddle, but when a piece needs shaped at either end and there's a third joining piece which also needs shaped to

accommodate the first piece... then it starts to get a bit of a pest!

Theshed - 29/9/17 at 09:26 PM

quote:

Originally posted by SPYDER

^^^^^^^^^ Hi there! How's the build going?

Slightly slower than global warming! I got distracted by building a 1962 morris for the daughter....back on it soon and still using a pile of mining

cutters from you thanks!

froggy - 30/9/17 at 12:19 PM

If it's going to be Tig welded I just cut a piece of filler rod and lie it in the gap then weld with a filler rod as normal

mangogrooveworkshop - 30/9/17 at 12:39 PM

https://goo.gl/images/dJgPAs

scootz - 30/9/17 at 07:49 PM

Cheers Peeps!

Can you trim the long ends of the oval to close the gap a bit?

Can you trim the long ends of the oval to close the gap a bit?