Hi,

Since I do not have access to a pipe bender, and do not want to fabricate pipe bender for this job only, is it OK to use

THIS to fabricate the roll-bar?

It does not have to be FIA approved, and no harnesses will be mounted to the rollbar. I do want some safety for the people inside te car!

Needless to say, I have full confidence in my own welding!

hmm nope, weight a ton too as I used this stuff to make a bull bar for a landy and it took two of us to fit.

Mk can supply a bar for not much money and it wall be a lot safer, make sure you add rear diagonal braces also

would a weld, or in this case several welds weaken the roll bar? as opposed to a single piece of steel being bent? are there any local companies to you that would bend some piping for you?

going by your other post I have no confidence in your welding

quote:

Same problem here! For stressed places I have tried to make the birdsh!t as nice as possible

For the non stressed hard-to-reach places (e.g. under brackets) I was planning on using the chemical metal as well, just to prevent dirt and water ruining my chassis in a couple of years.

You got me!

quote:

hmm nope, weight a ton too as I used this stuff to make a bull bar for a landy and it took two of us to fit.

What you need to bear in mind is that this rollover bar might one day save your life......or not.

It's not something upon which I would compromise particularly for the few bob to hire a bender for a day.

In my humble opinion.

Take care

John

[Edited on 29/10/08 by John Bonnett]

quote:

What you need to bear in mind is that this rollover bar might one day save your life......or not.

This is an interesting question, and the responses are even more interesting.

Are we saying that welding is not a satisfactory way of joining two pieces of tubing? Surely that's bad news for anyone who has a welded

chassis.

I personally thing that constructing a roll-over bar from premade bends and straight tubes by welding is too unconventional for me, but I would be

interested to read a convincing argument against it. I'm feel sure that were a such a roll-over bar to be put to actual use, it

wouldn't fail at the welds.

John

[Edited on 29/10/08 by mr henderson]

For competition use the MSA stipulate that the main transverse bar has to be bent from one piece of tube.

Depends on the weld...

If you purge it - then it's almost as good as single length...

Purge welding is tricky though...

quote:

For competition use the MSA stipulate that the main transverse bar has to be bent from one piece of tube.

quote:

I personally thing that constructing a roll-over bar from premade bends and straight tubes by welding is too unconventional for me, but I would be interested to read a convincing argument against it. I'm feel sure that were a such a roll-over bar to be put to actual use, it wouldn't fail at the welds.

For competition use the MSA stipulate that the main transverse bar has to be bent from one piece of tube.

Yes that's just what I was going to say too.

I seem to remember (and I'm sure I shall be corrected) from when I was studying metallurgy that the grain structure of the metal is changed in

and around the area of the weld. In the centre of the weld bead it is a cast structure adjacent to which is the heat affected zone followed by the

parent metal. In the case of drawn tubing there will be a longitudinal grain structure giving strength and integrity to the tube. The weakness will be

at the point where this ceases ie in the area of the weld.

As far as a chassis is concerned, it derives its strength from its design, loadings being transferred from one bulkhead to the next. The welds locate

the tubes rather than being the only means by which the chassis stays together. A bit like a piece of well made joinery, the strength is in the joint

not the dowel that holds it together.

It's many years since I did any metallurgy and I apologise if I have forgotten the detail but in principle, I believe what I have said is

basically correct and underlines my reasons for not welding a roll bar.

I await to be shot down!

John

@John bonnett

Your post does make sense. Me, being an mechanical engineering graduate have followed these lessons as well. Cold drawn (bent) steel has a higher

tensile strength. (remember teh graph showing tensile strenth of Fe360 in the tensile test?)

As I remember now, in the heat affected zone the the material is more brittle due to grain structure (austenite?? can't remember exaclty). Your

story on the chassis makes sense as well.

Good thinking pal!

quote:

Not even taking into account the bending of the chassis in this event....

[Edited on 29/10/08 by maartenromijn] [/quote]

It's actually worse than that.

The MSA consider the point to be drawn between the structure and the top of the roll bar - which takes the bonnet and nosecone out of the equation.

This is my interpretation - which is even worse.

[Edited on 29/10/08 by zilspeed]

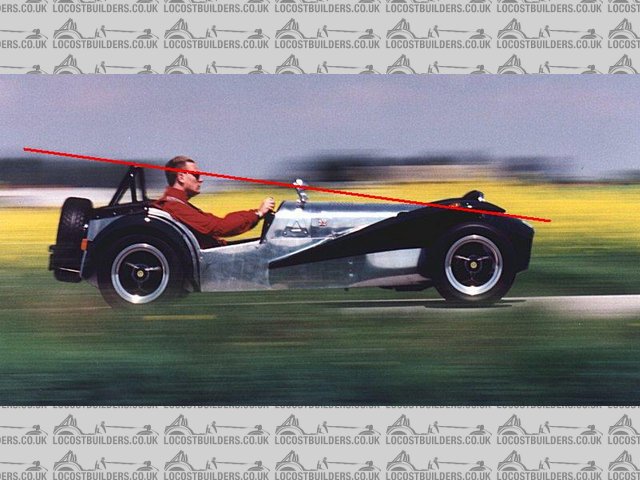

Rescued attachment Caterham.jpg

RoadkillUK - 29/10/08 at 05:35 PMIt just so happens that I have a pic of a MK Rollbar, it's a little old but I imagine they are the same.

John Bonnett - 29/10/08 at 05:54 PMI haven't seen a Blue Book for some time but I understood that the horizontal part of the hoop must be at least 2 inches above the top of the driver's helmet. If this is correct, the hoop in the picture would never get through scrutineering.

The one that safety Devices made for the Special certainly confirms my memory.

John

maartenromijn - 29/10/08 at 08:50 PM@roadkillUK: That's the one i'm looking for! thanks for the pic.

@John Bonnett: What is a blue book please? If I understand correctly the lower type rollbar does not provide any safety and is acceptable for SVA/IVA. If you want to race a locost in the UK you definately need a higher version. Correct interpretation?

John Bonnett - 29/10/08 at 09:21 PMAs far as I know, there is no obligation to have a rollover bar at all either for SVA or use on the road. I think however, it is a very desirable accessory!

I'm sorry I should have explained, the Blue Book is the Motor Sport competitors bible. It is issued by the Motor Sports Association, the governing body of motor sport in the UK and competitors and vehicles have to adhere to the laid down regulations conformity to which are checked before an event by the Scrutineer.

My own feeling is that if the roll bar meets racing requirements it should see you alright in the event of an accident on the road. That was my reason for mentioning the Blue Book. Clearly (well in my opinion) the one in the picture has little more than cosmetic value.

atb

John

kb58 - 30/10/08 at 02:33 AMLikewise in the US for the SCCA, one continuous piece of tubing for the main roll hoop. I wouldn't cut corners on this.

kb58 - 30/10/08 at 02:35 AMquote:

Originally posted by John Bonnett

I haven't seen a Blue Book for some time but I understood that the horizontal part of the hoop must be at least 2 inches above the top of the driver's helmet. If this is correct, the hoop in the picture would never get through scrutineering.

The one that safety Devices made for the Special certainly confirms my memory.

John

The really bad thing about the bar in that picture is there appears to be no padding directly behind the driver's head. Imagine getting hit from the rear at even 10mph. The driver's skull will take a real hit from that bar.

[Edited on 10/30/08 by kb58]

John Bonnett - 30/10/08 at 08:54 AMAbsolutely right. When passengering in a Caterham, we were stationary (having just spun) and another Caterham spun in sympathy and hit us back to back. No more than 10mph. I had a helmet but the back of my head hit the bar and the pain was as if I was not wearing a helmet.

John

MakeEverything - 1/11/08 at 10:28 PMquote:

Originally posted by mr henderson

This is an interesting question, and the responses are even more interesting.

Are we saying that welding is not a satisfactory way of joining two pieces of tubing? Surely that's bad news for anyone who has a welded chassis.

I personally thing that constructing a roll-over bar from premade bends and straight tubes by welding is too unconventional for me, but I would be interested to read a convincing argument against it. I'm feel sure that were a such a roll-over bar to be put to actual use, it wouldn't fail at the welds.

John

I Agree with John. If seam welded tubing is a concern, which i dont feel it is if its thick enough, then solid drawn could be used. If welded properly (without complicated purging) then the welds should withstand a rollover. The rear braces are crtical though, as the weak point will be where it joins the rear bulkhead and will bend or shear the mount if rolled.

As long as penetration in welds are correct then it should be as strong as you need it to be. Lets be honest, if youre going fast enough to roll one of these over, then your in trouble anyway, and the chances are that if something coming off the car doesnt spear you or squish you, then other injuries will.

"Motorsport is Dangerous"

If you roll it over on the road, then your one of three things;

A Victim of someone elses stupidity;

Driving like an idiot that deserves everything you get;

or in need of some more driving lessons. Sell it and get a 1.3 escort or other tin top.

[Edited on 1/11/08 by MakeEverything]

Echidna - 2/11/08 at 09:00 PMI would never use a welded rollover bar but... aren't the plates on which the bar mounts welded too? I mean, OK, the rollbar will not collapse, but the base will if not properly welded.

Ninehigh - 3/11/08 at 01:19 AMquote:

Originally posted by John BonnettIt's not something upon which I would compromise particularly for the few bob to hire a bender for a day.

In my humble opinion.

Take care

John

[Edited on 29/10/08 by John Bonnett]

Pfffrrrt lol...

Anyway now I'm being an adult again, I figured (I may well be wrong) but isn't a weld weaker than the metal it's welded by? Therefore in an impact event the welds would be the first part to go?