Is anyone on here doing water jetting/laser cutting?

I need a few bits cutting from mild steel, already have the DXF's etc

Thanks

Hi all,

Is anyone on here doing water jetting/laser cutting?

I need a few bits cutting from mild steel, already have the DXF's etc

Thanks

Hi Sera,

Iím planning to use Rob @ https://www.octagonprecision.com/about in the next week or so - customer service seems great.

Hope you are well.

Tim, why do you use waterjet rather than laser? Just wondering about the pros & cons of each?

How does it compare pricewise?

https://www.lasermaster.co.uk/

I had good service from these guys in the past, send them a dwg/dxf file, they will quote, you agree, parts arrive. I had inlet manifold plate and

smaller bits done in aluminium and exhaust manifold plate in steel. Worth and email for a quote.

Thanks all, some food for thought!

quote:

Originally posted by russbost

Tim, why do you use waterjet rather than laser? Just wondering about the pros & cons of each?

How does it compare pricewise?

What's minimum order for the water jet guy you recommended

It seems he does a fair amount of one-off work.

Do you know of Guttridge in Spalding? They have their own laser place next door, may be worth a try. And looks like they are remaining open.

https://www.laserfab.co.uk/

I use several companies for stuff at work but none are that good for smaller quantities like kit car stuff. I recently tried Laser Master (already mentioned) for a few personal bits and the price and service was excellent (some of the bigger companies could learn a thing or two from them!).

quote:

Originally posted by TimC

quote:

Originally posted by russbost

Tim, why do you use waterjet rather than laser? Just wondering about the pros & cons of each?

How does it compare pricewise?

Iíve used both over the years. For my purposes (one off kit car stuff) I donít think it makes much difference. I tend to go where the customer service is Good providing that its not prohibitively expensive.

In theory, laser is more accurate and cheaper but water can do thicker materials and also leaves surfaces without tarnishing. However, when you are talking one-offs, the business model and overheads of the firm will have as much to do with the price as any underlying efficiencies of the process.

We also use a wire-eroding contractor in work which is laser++ - another-level of accuracy and cost but comes with proper 3D versatility.

(we do a lot of 1off work)

(we do a lot of 1off work) Another vote for LaserMaster. co.uk

Got them to cut me a back plate for the ITG filter. The holes had to be offset, so couldn't buy an off the shelf item. Ended up costing less than

a blank from a motorsport seller and was accurate to 0.5mm and I drew in the hole for the air temp sender too.

Only problem was that I asked for 3mm thick, should have gone for 1.5mm.

My experience is that both technologies can achieve similar results as long as you specify what you want on the drawing. Laser tends to be cheaper on thinner materials, waterjet cheaper on thicker stuff for a given surface tolerance.

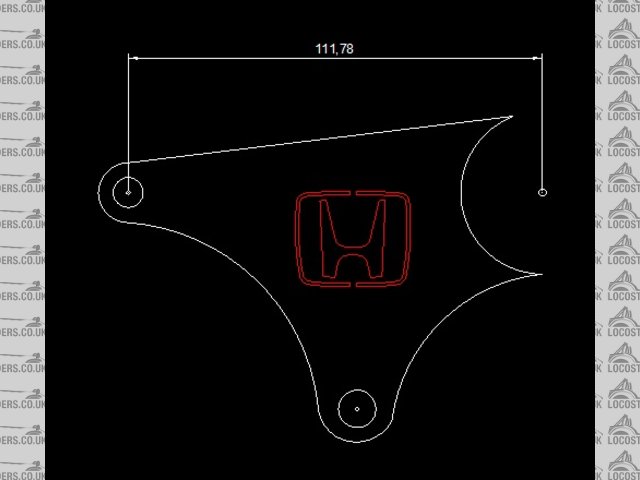

For info, I've just had a quote from Fractory.com to produce 2 (same price for 16!) of these in 5mm steel for £75. Drawing needs tweaking

first!

Description

I've just had a quote from a local supplier for the same job for £16!

That's a £75 min order price, hence same for 2 or 16. When I tried Fractory didn't get any responses at all

quote:

I've just had a quote from a local supplier for the same job for £16

I thought Iíd update on my experience with Rob at https://www.octagonprecision.com

I drew a profile with pencils and ruler yesterday, took a photo with my phone and e-mailed it to Rob.

Heís drawn it in Solidworks this morning and the parts should be with me Wednesday at the latest.

We had a good 15min chat on the phone too. Most of his usual customer base are on shut-down so heís reinventing his offer to meet the needs of the

likes of us. Iím really very impressed - he mentioned some of his blue-chip customers and if itís good enough for them...

Iíve never used the guy before, have no affiliation but think heís well-worth the recommendation.

TC