I've got the opportunity to buy a rotrex c15 kit, my plan was to turbo, but this is very very tempting!

I cant find any info on the web about the cbr being supercharged though, which isn't too good for me

Has anyone had any experience with a supercharger on a cbr900? or any other bike engine for that matter?

I've got the opportunity to buy a rotrex c15 kit, my plan was to turbo, but this is very very tempting!

I cant find any info on the web about the cbr being supercharged though, which isn't too good for me

Look at the TTS performance site detailing all the bikes and BEC they do

http://www.tts-performance.co.uk/

I guess the challenge is getting a drive off the crank that can support 30hp

Ill swap you the rotrex for an eaton m62. . .

quote:

Ill swap you the rotrex for an eaton m62. . .

Better and costs alot more! ! They are not even in the same ball park of products.

I would love a rotrex but can't front the cost when just the charger is the same cost as the whole build using an Eaton!

Got it!!

It was fitted for 2 drives! so virtually new

Rotrex C15 supercharger (I believe a C15-60, though there is only C15 stamped on it)

Mocal oil cooler

Oil tank (it runs off its own oil supply rather than the engines)

Oil filter

Ford rs turbo intercooler

1/2litre of rotrex traction fluid

60mm pulleys

toothed belt (not the ribbed v belts)

shaft that comes off the crank to the bottom pulley

£380!!!

I just need to machine the timing inspection cover to fit an oil seal for the shaft and knock up some brackets to hold the charger (which is getting

done at the moment by a friend.

Inlet plenum, intercooler pipework, lock up clutch, fuel pump and pressure reg and I think i'll be somewhere near running! maybe a bit of dyno

time and new jets for the carbs.... but I dont know yet

[Edited on 9/6/15 by Matt21]

Sounds like a bargain.

Where do you take the supercharger drive from?

I need to machine the timing inspection cover to hold an oil seal, then a shaft runs through that and bolts up to the end of the crank shaft, with 4

little pins that fit into 4 drilled holes on the timing disc, the pulley sits on the other end.

anyone know if I need to drop the compression?

how much by? how thick would the spacer need to be?

and where do I get one from?!

can I get, say a 1mm aluminium spacer laser cut and put a standard head gasket either side? should give me 1.5mm extra? too much, too little?

tts reckon it will be making 14psi boost with the current pulleys :| im not sure how right this is yet.....

http://www.locostbuilders.co.uk/viewthread.php?tid=180039

I had this in my book marks for when i was going to lower my CR.

Coincidently its also about a turbo zx9 so maybe of use.

It should answer your question about head gaskets. The company is called Faraday engineering, phone them, they have a calculator to work it out.

[Edited on 9/6/15 by bi22le]

quote:

Originally posted by bi22le

It should answer your question about head gaskets. The company is called Faraday engineering, phone them, they have a calculator to work it out.

I have a C15 Rotrex also sat waiting for find its way on to a bike engine

There's a chap called Winston who sprints an R1 (5VY) engined Caterham who uses the same charger and I think it takes its drive from there.

Look here as well for inspiration

http://www.mountainperformance.com/rx1%20supercharger%20pics.htm

Mike, can you explain why you don't think its such a good idea to run it off the end of the crank? I'd like to see a problem before I do

something silly!

I'm not sure where else it could be run off myself. the shaft is only around 4inches in length including the pulley so there wont be a great deal

of stress added

hobbsy, do you have any more info that would be helpful to me? or any idea on what you are planning on doing with yours, boost pressure, gaskets,

carbs etc etc?

Thanks

Another few questions....

what happens when I'm at 8k rpm and a take my foot off the throttle? I'll still have, lets say, 6psi of boost trying to get into my engine?

will this just 'stall' the supercharger?

do I need to fit a 'dump valve' to get rid of that pressure that cant get into the engine?

can the dump valve also be used to regulate the boost pressure? ie, anything over 8psi gets dumped as I'm still accelerating?

is a dump valve different to a recirc vavle?

I had a skim through the rotrex data sheet and it says to use a recirc vavle between the charger and the carbs, that needs back to the inlet of the

charger? wont this just keep putting the same pressure through to my carbs when I'm off throttle?

I think they run off a vacuum line also... I don't have a vacuum anywhere I don't think?!

Can anyone help with the vacuum lines?

Small update on the progress.

My mate has done a grand job of machining the crank cover to take an oil seal for the shaft to run through

Description

Description

And also modified the timing ring to hold the supercharger shaft so that it doesn't 'slip'

Description

Description

I just need a figure out how to tighten the crank cap up now as the nut is no longer on it!  I'm sure I'll find a way.

I'm sure I'll find a way.

I think my shopping list is complete and I'll just start ordering bits and pieces slowly.

First up is a lock up clutch!

my conversion will be very similar, that too is just an extended bolt which protrudes out of the casing allowing the fitment of the drive pulley, a

dump valve will vent unwanted boost off (to air or recirc)

I will try and find a useful link which got me into it in the first place.

That is a cracking price, ive hopefully sorted a deal out for the supercharger and drive kit for 1500 euros

here are a few pics from my research

Here is the srandard cover removed showing the m10 bolt which needs to be remade with another side to it to stick out of the casing

This is the plate being machined to hold the supercharger and allow a longer m10 bolt to driver the pulley

Assembled

I have a spread sheet which I have created which helps you design the driver pulley to give optimum performance, so going off my power graph I can

work out how to use the main areas of my powerband to drive the supercharger and hold its in it efficiency range as long as possible according to the

rotrex graph.

Hope this helps :-)

Keep us all posted with your progress

quote:

Originally posted by Matt21

Mike, can you explain why you don't think its such a good idea to run it off the end of the crank? I'd like to see a problem before I do something silly!

Mike - After getting the parts back off my mate, I'm pretty sure its going to be solid once its all bolts up! the shaft isn't very long so

there wont be much leverage, and the bolt fits in tight to hold it well!

That's a very neat mount! I'm going to have to make a bracket that will hopefully fasten on to the engine mounts.

I've been told by a supplier that a Forge 008 DV will be suitable for my set up, but I still don't know about the vacuum!  surely my

engine is supposed to have vacuum pipes somewhere?

surely my

engine is supposed to have vacuum pipes somewhere?

From talking to Dale at Bailey Performance the other week going charged on carbs is a pita to get set up properly.

Getting the carbs to be sealed is awkward, then you have to take them off to re-jet them everytime!

No vacumn pipes on an early blade engine, you can however use the carb balancing tapped holes in the block  just get some LPG injector nozzles for a

few pennies to screw in for your tube to hang off of.

just get some LPG injector nozzles for a

few pennies to screw in for your tube to hang off of.

Kev - I had sent an email to holeshot racing, they told me to post just my carbs to them, and they would send that back to me after theyve done

something to them and they would work?! I'm not sure how they know they will run right without a rolling road, but they said it was fine

Mark - would that provide me with enough vacuum to open a dump valve up?

TTS is the way to go they put the supercharger on top of the gearbox for car installs, very tidy.

Super excited to see this post. I had been contemplating the same thing for my Blade engine but couldn't find a lot of info on it, will keep an eye on this thread so please keep us all updated!!!

Well.... I went to fit the crank cover onto a spare engine to check that things went together OK. Only to find that the crank shaft is NOWHERE near

the center of the bloody timing hole!!!!

The only thing I can thing of doing is welding a plate into the hole instead of the disc and having a hole machined into it for the oil seal. How to

set the timing after that I don't know!

Any on got any other suggestions?

I have built a supercharged Blackbirdengine for my Caterham. I have not used it very much and its not quite finished but it ran well at a recent trackday. I have a rather detailed buildthread where you can see how I did. http://www.cbrxx.com/engine-airbox-exhaust-fuel-delivery/17093-twinscrewsupercharger-blackbirdengine-11.html

Hovsta !!

I have just replied to you on the CBRXX forum, welcome along here too....

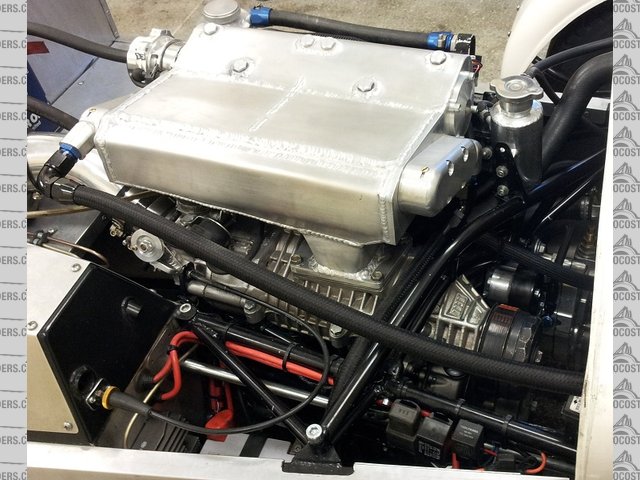

Heres a few pictures of engine with a crank driven C36-84, it used to have the 92? fitted. If theres anything you want give me a shout.

Look at this daddy....http://www.angelicbulldog.org.uk/press/dan-tec-engines-bikes/

[Edited on 26/8/15 by T66]

I dont think I'm on the cbrxx forum, I certainly cant log in anyway!

is that just a direct drive from the crank to the charger? very interesting!

That seems to be my first big issue, getting the pulley shaft through the engine cover (its not central with the hole I already have) Looks like

i'll need to make a whole new cover!

Unless anyone has any good ideas!

I cant get on that link you posted at the moment

Is yours an EFI engine? or carbs?

You have to be registered on http://www.cbrxx.com/ to be able to see the pictures.

My engine has direct drive from crank on ignitionside. Custom covers with support bearings.

Description

Description

Lots of pictures and details from build on http://www.cbrxx.com/engine-airbox-exhaust-fuel-delivery/17093-twinscrewsupercharger-blackbirdengine.html

Fuel Injected engine Matt

Hovsta what bhp have you achieved? And what injectors at what fuel pressure ?

Im not finished with setup and tuning on my engine and have not measured power yet. My intention was to increase power with 50 % and that would mean

10-11 psi of boost. As I have seen claimed horsepower to be everything from 130 rwhp to the Caterham numbers of 170 hp, that could mean everything

from 200-250 hp.

At the moment I use the original injectors and FPR. Injector dutycycle indicates that I need larger injectors. Until I get them I have lowered boost

to 7psi.

Any updates on this build?