zilspeed

|

| posted on 16/9/07 at 07:20 PM |

|

|

Twin engine transfer box - one for the engineers.

Right, before we go any further, I will never be doing such a thing as the old twin bike engine thing, but bear with me anyway.

Lots of discussion of such things recently and it always boils down to the transfer box costing a fortune.

So, I'm sort of thinking there must be a cheaper way of doing it.

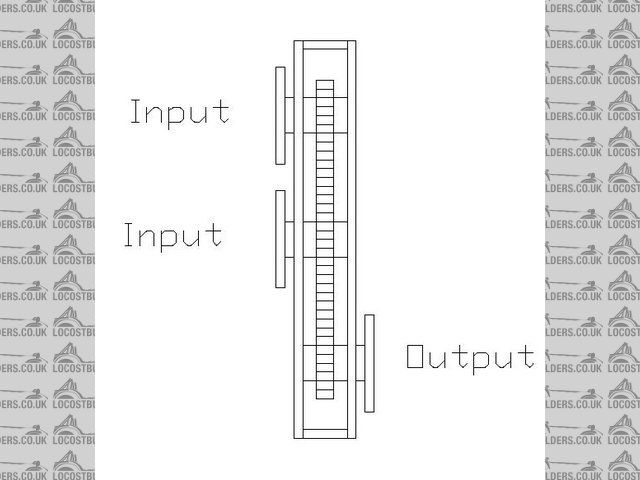

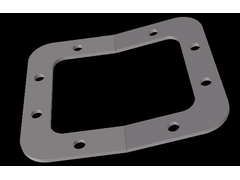

Have a look at this idea. Proportionally, it's a bit out, but the layout is essentially right. It's really three shafts linked by a chain.

Two of the shafts are input, one is output.

We would be talking about commonly available shafts, probably RWD gearbox tailshafts.

Internal sprockets would be bike front sprockets probably and the chain would be bike as well.

The case would be fashioned from 10mm thick aluminium plate cut and drilled suitably accurately.

Err, that's about it.

Discuss.

[Edited on 16/9/07 by zilspeed]

Rescued attachment xfer box.JPG

|

|

|

|

|

Simon

|

| posted on 16/9/07 at 07:24 PM |

|

|

Need an idler gear between two inputs or you rip all teeth off as soon as second engine started Maybe another depending on required diff rotational,

compared to engine rotation. Maybe another depending on required diff rotational,

compared to engine rotation.

Simple design though!

Edit: Oops just read it Hadn't noticed the chain bit!! Hadn't noticed the chain bit!!

ATB

Simon

[Edited on 16/9/07 by Simon]

|

|

|

blakep82

|

| posted on 16/9/07 at 07:40 PM |

|

|

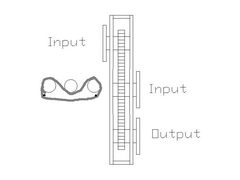

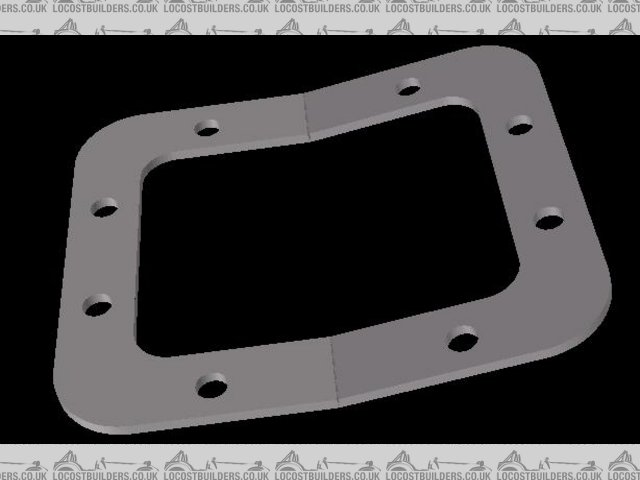

i would have thought, for 2 reasons, and over and under arrangment would be good.

1) it would have to be really wide for 2 engines to sit side by side

2) the chain on the middle gear would only be on 2 or 3 teeth at a time.

don't know, just a though. i think fitment and space would be the thing here

xfer

________________________

IVA manual link http://www.businesslink.gov.uk/bdotg/action/detail?type=RESOURCES&itemId=1081997083

don't write OT on a new thread title, you're creating the topic, everything you write is very much ON topic!

|

|

|

zilspeed

|

| posted on 16/9/07 at 08:06 PM |

|

|

The over and under arrangment is fine apart from all of the shafts needing to rotate in the same directions, which your arrangement does not allow.

It would however be relatively simple to have adjustable idlers on the outside providing tensioning on the chain runs between the sprockets.

|

|

|

blakep82

|

| posted on 16/9/07 at 08:08 PM |

|

|

i put the second engine over the other side to allow for it turning the opposite way, and allow both engines enough space

________________________

IVA manual link http://www.businesslink.gov.uk/bdotg/action/detail?type=RESOURCES&itemId=1081997083

don't write OT on a new thread title, you're creating the topic, everything you write is very much ON topic!

|

|

|

ed_crouch

|

| posted on 16/9/07 at 08:29 PM |

|

|

It wouldnt allow the engines to load share.

The only place Ive seen this kinda thing done (2 sources into 1 output) is with an epicyclic torque summer.

Having said that, there is a school of helicopter design called "Split torque". That is bascially what you're describing.

I think it could work, but if one engine goes sick, the other engine will see lots of load, as its then the only one doing any work, AND driving a

sick 2nd engine too.

Also, dont use just one chain, as the middle sprocket is only in contact with precious few teeth, and would probably slip. Have 2 sprockets on the

middle shaft, with a sepaerate chain for both the other engine and the drive.

Ed.

I-iii-iii-iii-ts ME!

Hurrah.

www.wings-and-wheels.net

|

|

|

rf900rush

|

| posted on 16/9/07 at 09:43 PM |

|

|

Hi

Why not make it even simpler.

Remove the top Spocket !

As they are all connected why not have one input straight through.

Martin

|

|

|

Simon

|

| posted on 16/9/07 at 10:11 PM |

|

|

I think you may have a point

ATB

Simon

|

|

|

thomas4age

|

| posted on 17/9/07 at 12:24 AM |

|

|

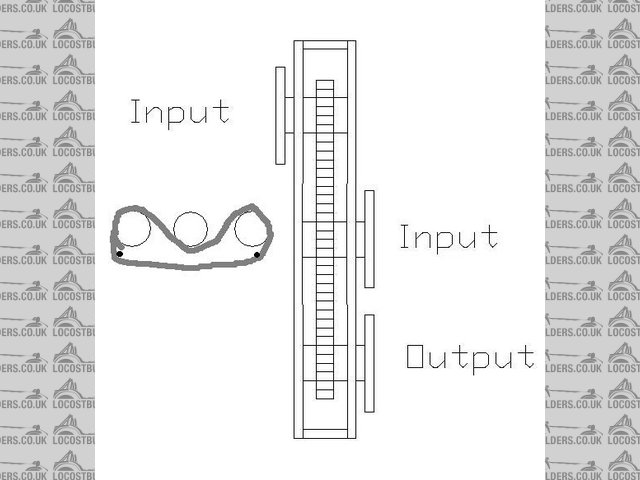

If you can mount the engine back to back the idea of using one input shaft can do and is the smallest.

but if you can't or don't want to mount the engines like that and they need to bee in the same arrangement as the Zcars tigers had you might

want to do this

it remains to be seen if the direction of rotation is OK in this way,

I wouldn't use chains or anything just a few 1:1 (4th) gears from a strong gearbox

in an enclosed box filled with transmission oil. I understand the MT75 has strong gears, you need 2 firts motion shaft gears and one from the second.

make up axles that sit on bearings and have shaft flanges on one end,

it's a load of work but it shouldn't be to hard to make something like that if you know someone with a good lathe. The box itself could be

made from steel plate or CNCd from solid alloy. oilseals for the flanges should also be availeble in every size you want so

twin engined coupler box

grtz Thomas

[Edited on 17/9/07 by thomas4age]

If Lucas made guns, Wars wouldn't start either.

|

|

|

02GF74

|

| posted on 17/9/07 at 09:02 AM |

|

|

I proposed one such idea a littrle while back.

The arrangement I had in mind is to do away with the bike engine gearboxes but to mate the two crankshafts of counbter-rotating engines together with

gears or chains.

One of the engines drives a smaller gear that then turns a larger central gear to give a drive ratio of 1:2 so is of suitable rpm for a car

gearbox.

gear surround

|

|

|

sgraber

|

| posted on 20/9/07 at 09:37 PM |

|

|

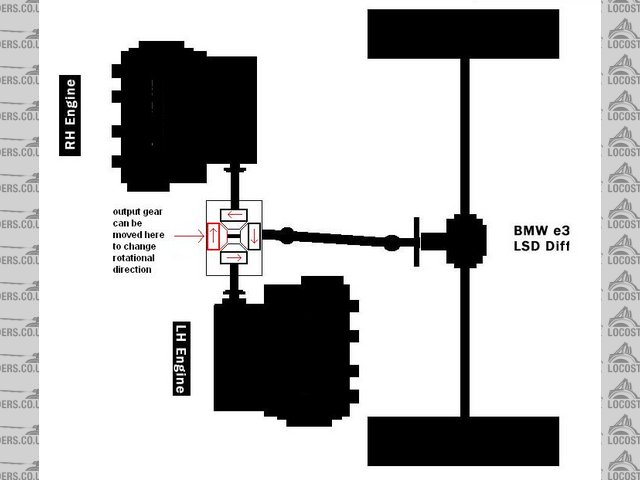

I have 2 hayabusas sitting in my garage right now alongside a BMW e30 LSD diff and some big ass chains/sprockets. All for the dual busa Bala that my

friend Rob is building. This is how we are going to arrange the driveline.

Chain Drive for dual BEC sketc

Steve Graber

http://www.grabercars.com/

"Quickness through lightness"

|

|

|

akumabito

|

| posted on 21/9/07 at 11:02 AM |

|

|

That's a really wide setup though. Not suitable for a locost-type vehicle at all. How did they squeeze it in the Tiger Z100?

|

|

|

Paul TigerB6

|

| posted on 21/9/07 at 11:40 AM |

|

|

quote:

Originally posted by akumabito

That's a really wide setup though. Not suitable for a locost-type vehicle at all. How did they squeeze it in the Tiger Z100?

By taking a huge chunk out of the passenger side footwell and putting the engine right back against the scuttle. Some pics here

http://www.tigersportscars.co.uk/cars/tiger-z100-main.php

I have been in the Z100WR (with the front engine turned around to power the front wheels) and lets just say it was pretty short on legroom. Then again

you sit partway into the foetal position which is what i felt like doing during a 2.9s 0-60mph run into the first corner at Curborough

|

|

|

MikeR

|

| posted on 21/9/07 at 02:10 PM |

|

|

isn't the length of chain on the left hand engine going to cause problems wearing out with it being so short & on the right hand being so

long & lacking tension?

(i'm just remembering comments NS Dev has made about expected chain life on his grass track racer)

|

|

|

NS Dev

|

| posted on 21/9/07 at 02:24 PM |

|

|

MikeR has hit the nail on the head!!!

None of the chain transfer boxes will work with any level of power, let alone a pair of busas.

The short chains are too short, and they overheat in minutes or less, seize their rollers and explode in a shower of bits.

I have seen it happen a fair few times on autograss cars.

Chain length is critical, take a look in an online chain catalogue and see what centre to centre distances are recommended!!!

I have broken all the rules, but I will be using 3/4" pitch 630 drag race chain rated to over 500hp, one per engine, and I expect to spend a

fair bit on replacing them, but then my races are only 5 minutes long!

The problem that Radical had with their early endurance racers was chain life, which is why Quaife designed and built their transfer box for the SR3

Retro RWD is the way forward...........automotive fabrication, car restoration, sheetmetal work, engine conversion

retro car restoration and tuning

|

|

|

NS Dev

|

| posted on 21/9/07 at 02:29 PM |

|

|

PS not sure what running the chain in oil will do. It will certainly extend its life.

PPS, with ref to the original point, the best way to do what you are looking at is to use silent chain (borg warner silent chain). This runs at very

high speeds and has not rollers, but does need to run in oil. It can however run on very short length runs. Take a look at the chain transfer units in

range rover and sierra XR4x4 transfer boxes for inspiration.

Me and a mate built a similar box to ehat you are talking about, out of a length of heavy wall steel box section with bearing bosses welded on and

bored through, then with a silent chain drive inside, this was to drive the 2 rear diffs of a 6wd, 6 wheel steer, 6 wheel independent suspension off

roader that we built.

Retro RWD is the way forward...........automotive fabrication, car restoration, sheetmetal work, engine conversion

retro car restoration and tuning

|

|

|

thomas4age

|

| posted on 21/9/07 at 03:26 PM |

|

|

It will go to pieces in no time in that set-up, which will slam the parts in the other working engine, thus costing you 2 engines because of one chain

failure.... not good.

the tigerz100 (rwd) had a sort of transferbox like in my picture if I'm not mistaking,

chain issues are the reason that TAD MK etc etc went north south on the installs and fitted the engine to the diff with only a rubber vibration damper

in between. + much cleaner install1

you could do that with 2 engines but it should be gears in the coupler box. you could even decide to run 5 gears and have a center take of, to get

spacing between engines a little better.

grtz Thomas

If Lucas made guns, Wars wouldn't start either.

|

|

|

sgraber

|

| posted on 21/9/07 at 03:40 PM |

|

|

I think maybe I have hijacked the thread a bit, but I do appreciate the advice from people that have been there - seen that.

How about this one?

Idea 2 chain/direct drive bec

Steve Graber

http://www.grabercars.com/

"Quickness through lightness"

|

|

|

thomas4age

|

| posted on 21/9/07 at 04:52 PM |

|

|

hey steve,

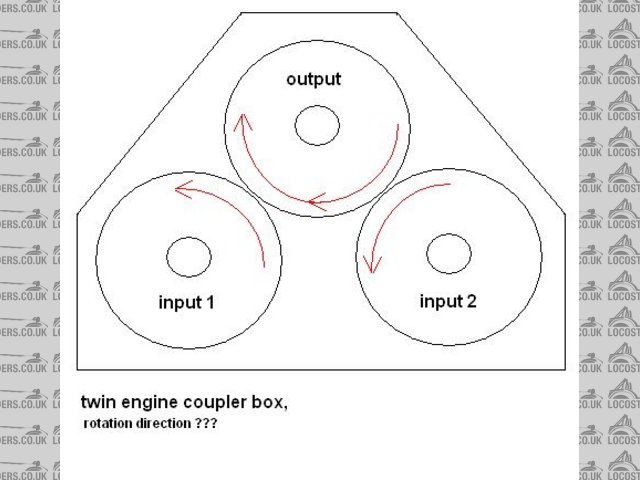

Maybe when you have the room to build the above mentioned set-up, you could also build it like this,

twin engine coupler box idea 2

maybe if you weld up a diff in the right manner (or not at all) you could get away with this, otherwise 3 gears need to made and a box to carry

them.

grtz thomas (chain hater)

If Lucas made guns, Wars wouldn't start either.

|

|

|

sgraber

|

| posted on 21/9/07 at 05:06 PM |

|

|

quote:

Originally posted by thomas4age

hey steve,

Maybe when you have the room to build the above mentioned set-up, you could also build it like this,

grtz thomas (chain hater)

Listen you chain-hater....  I actually do have the room, as I have a middy engine bay with over 39" of clearance side to side between the

rails. Also about 32" clear to the firewall in front of the half-shaft centerlines I actually do have the room, as I have a middy engine bay with over 39" of clearance side to side between the

rails. Also about 32" clear to the firewall in front of the half-shaft centerlines

Steve Graber

http://www.grabercars.com/

"Quickness through lightness"

|

|

|

thomas4age

|

| posted on 21/9/07 at 05:28 PM |

|

|

Hey steve,

well then, you know you can!

was just thinking a bit more, a normal diff would give an extra ratio which you probably don't want, but 3 spider gears or 3 input gears could

do the trick, seems to me the helical form is OK on ford live axle ones....

getting the backlash right and the paly inbetween the gears, is the biggest problem I think which good machining can fix for a large amount.

grtz Thomas

ps: if you get the pistons in the right place before putting the axles in position you could even play around with the soundtrack of the engines

hahahaha!

If Lucas made guns, Wars wouldn't start either.

|

|

|

akumabito

|

| posted on 21/9/07 at 06:21 PM |

|

|

quote:

Originally posted by NS Dev

a 6wd, 6 wheel steer, 6 wheel independent suspension off roader that we built.

Got more information / pictures of that??

Hm, maybe best to send me a PM, no need to hijack this thread..

|

|

|

sgraber

|

| posted on 24/9/07 at 11:19 PM |

|

|

I do realize I hijacked this thread and for that I apologize, but the deed is done, so I might as well continue...

How about this layout? It's an inline 8

Description

Connect the engines at the cranks. This would on the surface appear to be a really good idea. The exact details on how this would be accomplished are

a bit murky though. Some hellacious adapter.

But this solves some real problems in previous ideas.

The rear differential now mounts in standard BEC middy fashion in a carrier with sealed outer bearings.

Now the left side engine can have it's transmission guts removed for further weight reduction. The engines are timed together and can be

controlled with one ECU. There is only one gearbox, preventing the possibility of a mis-shift in one box grenading the second transmission.

If a stronger chain is required, two chains could be duplexed side-by-side from engine to diff.

Comments?

Steve Graber

http://www.grabercars.com/

"Quickness through lightness"

|

|

|

britishtrident

|

| posted on 25/9/07 at 06:45 AM |

|

|

quote:

O

But this solves some real problems in previous ideas.

Comments?

Crank on the second engine will snap

[I] “ What use our work, Bennet, if we cannot care for those we love? .”

― From BBC TV/Amazon's Ripper Street.

[/I]

|

|

|

MikeRJ

|

| posted on 25/9/07 at 07:41 AM |

|

|

quote:

Originally posted by britishtrident

quote:

But this solves some real problems in previous ideas.

Comments?

Crank on the second engine will snap

That's a bit unfair BT, there's a good chance that the clutch or gearbox in the second unit will expire before the crank snaps

|

|

|