Fred W B

|

| posted on 13/2/23 at 08:23 AM |

|

|

CANAMSA update

Hi all

Itís been a long time since I posted, but I have been making good (if slow) progress on my project. I have yet to find a convenient way to download

photos from my phone, configure and upload them suitable for posting and as Iím trying to spend every bit of free time I have in the garage working on

the project my posting has suffered.

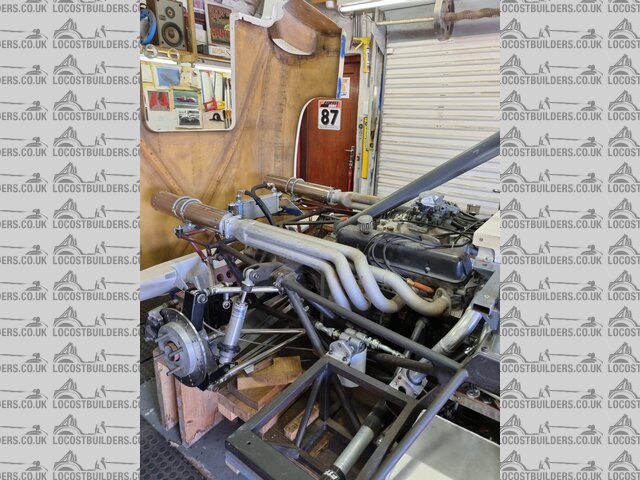

Iím now well advanced with a dry build, things accomplished since I last posted:

All wishbones made up.

Drive shafts made.

Engine cooling fitted and plumbed - Radiator, header tank, swirl pot, electric water pump mounted. 38 mm dia piping made up in aluminium and stainless

steel and mounted in aluminum brackets.

Brake and clutch hydraulics run in flex braided right through.

Handbrake cables made and run.

Fuel tanks (2 off Left and right, and centre consolidation tank) made and mounted.

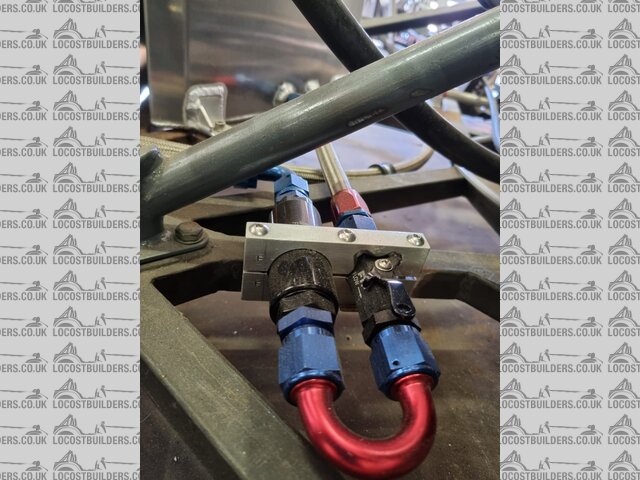

Fuel system pre filter, pump, regulator, post filter, connection valves, plumbed in -8 and -6 braided hose with AN fittings.

Oil cooler, thermostat, remote filter mounted and plumbed in hydraulic hose and BSP fittings.

Gearshift finalized (still mock up parts) and cables made and run.

All above systems require mounting brackets and pipes / cables securing with P clips. I donít like to rivet on P clips so have added a lot of brackets

to bolt to. Where brackets will be inaccessible once the chassis is panelled weld nuts are required to the back of the brackets.

Carburetor rebuilt.

Exhaust silencers mounted.

Body fit: Scuttle fit finalized.

All nose mounting points made and fitted.

Current focus is:

Making up accelerator pedal, carb linkage and cable.

Finalize tail mounting hinges and latches detail.

Door mounting hinges and latches parts being made.

Anti-roll bar parts being made (design and mounting is complete).

Once the above is done the only remaining system to fit and make brackets for is the full electrical and dashboard.

Then strip, paint chassis and the various subframes and then do final build. First step will be to panel the chassis.

I do intend to document and share the final build.

[Edited on 13/2/23 by Fred W B]

You can do it quickly. You can do it cheap. You can do it right. Ė Pick any two.

|

|

|

|

|

HowardB

|

| posted on 13/2/23 at 08:54 AM |

|

|

I was thinking of your build the other day and wondering how you are gertting on -

It is looking fantastic (two fantastic) and awesome.

I am looking forward to future updates

Howard

Howard

Fisher Fury was 2000 Zetec - now a 1600 (it Lives again  and goes zoom) and goes zoom)

|

|

|

snapper

|

| posted on 13/2/23 at 09:48 AM |

|

|

Looks a well thought out and well executed build Fred

Good job mate

I eat to survive

I drink to forget

I breath to pi55 my ex wife off (and now my ex partner)

|

|

|

adithorp

|

| posted on 13/2/23 at 02:36 PM |

|

|

Looking good!

Seems like youre in sight oof the finishing line. There were times when this seemed duch a mammoth project with such attention to detail, that I

wondered if you'd ever get it done.

"A witty saying proves nothing" Voltaire

http://jpsc.org.uk/forum/

|

|

|

Fred W B

|

| posted on 13/2/23 at 05:48 PM |

|

|

Thanks for the responses guys

Adithorp, they say that "perfection is the enemy of progress" , I'm trying to get over that

You can do it quickly. You can do it cheap. You can do it right. Ė Pick any two.

|

|

|

MikeR

|

| posted on 15/2/23 at 10:40 AM |

|

|

I love seeing these updates, keep going. I'm looking forward to seeing the first drive video (one day)

|

|

|

Fred W B

|

| posted on 20/11/23 at 05:09 PM |

|

|

I have now 99 percent completed the dry build:

Body mounted and gapping finalized. Hinges, latches, etc installed.

Fuse box and relays mounted and the dash mocked up (real one still to be cut in one piece ). I splashed out on a set of Stack gauges. All connections

and wiring for these planned and the wiring is mostly laid in.

Last week I had all 4 wheels on for the first time ever and I weighed the car as it stands now (excluding chassis and cockpit skin panelling, fluids,

anti roll bars and seat belts). I'm still under 800 kg (1760 lbs) which I am happy about.

|

|

|

jps

|

| posted on 20/11/23 at 06:30 PM |

|

|

It looks fantastic. Just goes to show that, even if takes a long time to get there, amazing projects can come to fruition!

|

|

|

Mr Whippy

|

| posted on 20/11/23 at 07:30 PM |

|

|

Total dedication has certainly paid off, looks perfect

|

|

|