35mm inlet trumpets?

RazMan - 8/10/10 at 10:18 PM

I am still looking at my ITB project on my Duratec V6 and have sorted out how to make the new spindles and add the 'missing'

butterflies.

I have another problem which has got me stumped so far and I thought of you guys

I have bought some really nice 45mm bore trumpets (5" long) from Thailand (really good quality btw) and I need to blend the round 45mm bore into

twin 35mm bores over a length of about 70mm - a kind of Y connector if you like. Gas flow is obviously a priority here.

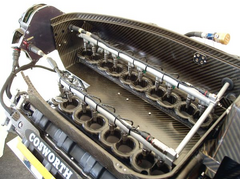

LIM closeup

I have had a word with a local CNC company and they quoted me a horrendous price for making a manifold from alloy billet. This will blow all of my

budget so I need to think of alternatives.

I did think of fitting 12 individual trumpets but as they are so close to each other I doubt that they would play nicely together (the tapers would

clash) unless they are cut and welded together, which gets expensive again.

*edit* I just re-thunk and I could simply lean the trumpets outwards a few degrees to allow them to sit side-by-side, so if anyone knows of any

longish 35mm bore trumpets I am all ears.

........ so any ideas guys?

[Edited on 8-10-10 by RazMan]

interestedparty - 9/10/10 at 05:37 AM

Slightly off-topic, but possibly of interest- Have you spoken to Clairetoo about her Mazda V6 ITB conversion? She reckons she could sort something out

for the Ford version.

We have exchanged U2Us about it and the price is VERY attractive.

MikeR - 9/10/10 at 07:35 AM

Slightly off topic - where did you get the trumpets from?

RazMan - 9/10/10 at 08:23 AM

interestedparty - Claire and I have exchanged U2Us recently but I was originally looking to get maching done to my spec which she couldn't do

because she had sold her milling machine. Like her, I have the skills but no kit  so I hi-jacked a friend's workshop and got cracking. AFAIK

Claire's ITB kits are bike TBs and I really wanted to use the Ford stuff if possible as it will end up being much cheaper to produce in volume

form

so I hi-jacked a friend's workshop and got cracking. AFAIK

Claire's ITB kits are bike TBs and I really wanted to use the Ford stuff if possible as it will end up being much cheaper to produce in volume

form

MikeR - I got the trumpets from www.akunar.com for a very good price ...... and I will probably be selling them on soon if you are interested

They are listed under 'Filters' and are the 5" silver version.

matt_gsxr - 9/10/10 at 08:35 AM

gpz1100 83-84 models used 35mm i.d. TBIs.

TBI trivial,

Matt

matt_gsxr - 9/10/10 at 08:41 AM

wow that www.akunar.com site is proper locost. Awesome find.

Matt

RazMan - 9/10/10 at 08:42 AM

quote:

Originally posted by matt_gsxr

gpz1100 83-84 models used 35mm i.d. TBIs.

TBI trivial,

Matt

Matt - The V6 has dual 33/35mm ports for each cylinder so I would need TWELVE then

matt_gsxr - 9/10/10 at 10:43 PM

12 trumpets. 12 x anything = loads of cash

Sounds like about 8 too many for my liking.

Good luck

Matt

clairetoo - 12/10/10 at 08:07 PM

I've been thinking (strange , but true...) - how about shorter `Siamese'd' trumpets ?

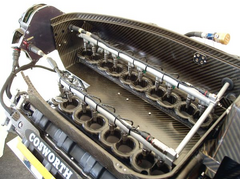

Something like this ?

Cosworth F1

Would be a challenge to make

RazMan - 12/10/10 at 10:47 PM

Great minds think alike Claire ... and so do ours it seems

That is quite a wacky looking setup there! I assume that is the V10 F1 engine using a similar setup to mine with extra butterflies but are those

injectors above them? wow!

How would the length of those teeny weeny trumpets affect the power? I assume it would push all of the torque waaay up the rev range which might be

fine for a race engine but a bit impractical for a road car. Impressive none the less

I was thinking a tad longer - maybe 100-125mm?

[Edited on 12-10-10 by RazMan]

iti_uk - 13/10/10 at 05:52 PM

Or what about machining the ports so you have one ob-round before it splits for the butterflies instead of two seperate ports. Then all you need is 6

ob-round trumpets... Probably simpler to make than siamesed twins.

Chris

RazMan - 13/10/10 at 07:11 PM

That's a very good and logical idea Chris, and it had occurred to me at first. Unfortunately the butterflies are quite close to the top surface

of the inlet manifold so the blending might not be very gradual and gasflow might suffer as a result.

It would appear that the trumpet part of my project is going to be far more expensive than the butterfly part, which was quite simple by comparison

(just remaking the spindles really). I may have to rethink and look at machining the ports after all, and then sort out some obround trumpets.

iti_uk - 21/10/10 at 10:36 AM

Or how about go a step further - machine the ports in that lower manifold to be totally obround (to the larger diameter of the two), then do the

blending in the heads themselves...? All you need then is ob-round butterflies and you're sorted.

Chris

RazMan - 21/10/10 at 11:09 AM

Actually I have now had an alternative & Locost idea

If I slice an alloy trumpet and butt it up to another one, is it feasable to use PU adhesive or JBweld to bond them together & also to the

baseplate?

Obviously TIG welding would be preferable but at this stage I just want to prove that the overall design works ... plus TIG ing them is expensive for

a one-off.

They would look something like this ....

Image deleted by owner

ps. Chris - obround butterflies would be a challenge to make!

[Edited on 21-10-10 by RazMan]

interestedparty - 21/10/10 at 12:20 PM

quote:

Originally posted by RazMan

Actually I have now had an alternative & Locost idea

If I slice an alloy trumpet and butt it up to another one, is it feasable to use PU adhesive or JBweld to bond them together & also to the

baseplate?

I'm quite sure a decent bonding job will be entirely adequate. Especially considering many inlet manifolds are made completely from plastic.

iti_uk - 21/10/10 at 02:46 PM

quote:

ps. Chris - obround butterflies would be a challenge to make!

No harder than "round" butterflies. Just a quick outline in CAD and a water-jetting later, hey presto!

Your solution does look quite nice, though. Certainly easier to do than all the machining/porting involved in my idea.

Chris

[Edited on 21/10/2010 by iti_uk]

so I hi-jacked a friend's workshop and got cracking. AFAIK

Claire's ITB kits are bike TBs and I really wanted to use the Ford stuff if possible as it will end up being much cheaper to produce in volume

form

so I hi-jacked a friend's workshop and got cracking. AFAIK

Claire's ITB kits are bike TBs and I really wanted to use the Ford stuff if possible as it will end up being much cheaper to produce in volume

form