I think ford released a road going Formula Ford car not long ago. Looks incredible but did appear to essentially cover the wheels better and stick some lights on

Hi all,

Its been a long while since I last posted here, but I think its time to restart my dream of building a car from scratch! Having now got a lot more

experience around cars, including finishing my first total restoration, I hope that something may actually come of this project. My hope is to build

a car similar to the Lotus 32B, adapted for road use, whilst retaining the attraction of the original! It certainly wont be practical, but it will be

beautiful! Please keep an eye on this thread, and if you have any suggestions regarding a transaxle gearbox or have experience of building a monocoque

chassis and are willing to share please let me know!

Sounds like a great but challenging project.

As for transaxkes have a look at audi a4/6, passat and porsche boxster.

I would strongly recommend reading the iva manual as I think you will identify some real challenges trying to satisfy the iva regs and keeping the

lotus 32b style.

Worth also looking up the era hss, similar idea but as far as I know no-one has managed to iva one yet.

All the best and do keep us updated.

Thanks, I shall certainly look into those!

Its been a little while since I last looked through the manual, so will have a few busy evenings...

Not one I've heard of, but i shall take a look!

quote:

Originally posted by Ugg10

As for transaxkes have a look at audi a4/6, passat and porsche boxster.

Thanks for the photos, definately food for thought! Over the last few week I've managed to accrue a large number of photos of the car in various

states of completeness, so something to work from...

Also with the gearbox, that sounds like something I definately want to look into.

Although obviously not in keeping with the period feel, I'm looking at using a modern zetec engine here simply for convenience, as im fairly

familiar with them...

quote:

Originally posted by paddywil

Although obviously not in keeping with the period feel, I'm looking at using a modern zetec engine here simply for convenience, as im fairly familiar with them...

What material are you thinking of for the monocoque?

I'm very interested to see how this project goes. I'd love a road going racecar, forget the practicalities!

I think ford released a road going Formula Ford car not long ago. Looks incredible but did appear to essentially cover the wheels better and stick

some lights on

Thanks for all the interest! I'll do some research on the engines you've suggested, might well fit the bill.

I'm planning on using aluminium for a large portion of the monocoque, with the possibility of using steel in some locations, sucu as where the

suspension mounts are.

Haha my family really don't do practical cars, bearing in mind my Dad's daily driver is a noble m12 :p

They did, same sort of thing as I'm planning on doing here - it's worth looking at the vanwall GPR V12 too, as this is a similar concept.

I'll hopefully be uploading some sketches over the next couple of days for what I've got in mind with regards to wheel guards, lights

etc...

In the meantime, my current list of transaxle gearboxes to consider stands at:

Porche boxter

Vw beetle

modified subaru

Audi a4/6

If you've got any other suggestions please let me know!

In terms of transaxles, the Boxster, the Audi A4/6 and Passat 6 speeds are all basically the same box but with slightly different gear change

mechanisms and comes in a variety or ratios.

Remember the beetle has the engine behind it so if you are looking for mid endine then the gearbox will need flipping and so may need things like oil

vents/feeders/plugs etc. reworking, this is what the big boys who build Ultima/T70/GT40's do with the Porsche 911 G50 box.

There is the oldschool UN1 box as found in some Renaults and used in some GT40 replicas and the Lotus Europa/Esprit.

The Scooby box is a 4wd box so the drive the rear axle need to be locked off, the SDR V-Storm does this.

The Alfa 33/Alfasud also has a transaxle for it's boxer engine IIRC as well.

Depending on your idea of fun you could used a bike engine and link the sprocket to a "normal" RWD diff either via a cush donut or a very

short propshaft. The Fisher Menace and the MEV Atomic used this arrangement. can be very light, sequential gears but you will need to engineer a

reverse probably via an electric motor for IVA.

For monocoque design have a look at Tornado's GT40, they have a spaceframe, an aluminium and a carbon version of their tub so you can compare the

designs. Also the GTM libra has a composite monococque design. And there is also the Quantum Extreme what has a stainless folded monocoque design.

Robin Hood also tried a folded stainless design but did not sell many IIRC.

Last thought for now would be to look at the engineering of the Spire GT as this can use the Audi drive train in the rear. Also dig out some old info

on the Edge Devil which is a more modern version of what I think you are trying to achieve, a bit chunky but you may get some ideas from what they

did.

Very last thought, have you thought about making the monocoque out of a composite sandwich structure using woven fabric skins (getting the weave

directions right between the layers is the key) and a polyeurothane foam core (Rohacel is the gold standard but expensive), this could produce a very

light and stiff tub and does not have to be too expensive. Subfrmaes can then be bolted onto the front and rear to hold the oily bits and has the

potential, with quick release plugs/lines, to allow quick changes of the rear engine cradle. This was used in the Scultpural Engineering Larini (later

the GTM Ballista) and is used in Yacht building.

Hope this brain dump helps.

What an excellent brain dump that was!

I hadn't thought of the need to flip the box for the mid engine layout, definately food for thought!

The Scooby box is looking appealing at the moment, with the mod required seeming to be relatively common.

I'm quite familiar with the Tornado GT40, (having wanted one for a very long time!) Ill have to dig out all the old pics I have...

The Edge Devil is sort of what I'm aiming for, though as you say it is a little 'chunky' for my liking. Definitely something to use

for ideas though.

I can't honestly say that I'd thought of building the monocoque like that, but its a very interesting concept... The method sounds like it

would definately keep costs down, and be a pretty flexible method of building. I like the sound of the ability to carry out easy engine swaps -

endless possibilities!

Thanks for all that, I can see a lot of reading coming on!

Of course, it would always be possible to build a spaceframe chassis instead... what do people think with regards to one or the other?

quote:

Originally posted by Ugg10

Remember the beetle has the engine behind it so if you are looking for mid endine then the gearbox will need flipping and so may need things like oil vents/feeders/plugs etc. reworking...

quote:

Originally posted by Ugg10

....have you thought about making the monocoque out of a composite sandwich structure using woven fabric skins (getting the weave directions right between the layers is the key) and a polyeurothane foam core (Rohacel is the gold standard but expensive), this could produce a very light and stiff tub and does not have to be too expensive. Subfrmaes can then be bolted onto the front and rear to hold the oily bits and has the potential, with quick release plugs/lines, to allow quick changes of the rear engine cradle. This was used in the Scultpural Engineering Larini (later the GTM Ballista) and is used in Yacht building.

Thanks, I'll see if i can find a copy of that book

quote:

Originally posted by WallerZero

I think ford released a road going Formula Ford car not long ago.

They were posted more to look at the monocoques than anything else I think...

The Haynes single seater is certainly more like what I'm aiming for, essentially a 1960s style formual car, adapted for street use.

There are plenty of problems which could be thrown up by the IVA  Although I think none of them will be insurmountable....

Although I think none of them will be insurmountable....

Just to clarify, this is what I'm aiming for

https://c2.staticflickr.com/4/3181/2911835272_bff876e44f.jpg

The Furore goes thro' IVA without any real issues, but then I designed it that way from the start, there are a no. of traps to avoid, make sure

you have a good read of the IVA manual BEFORE starting anything as modifying later is always 10 times harder. If you want to PM me feel free, happy to

offer guidance

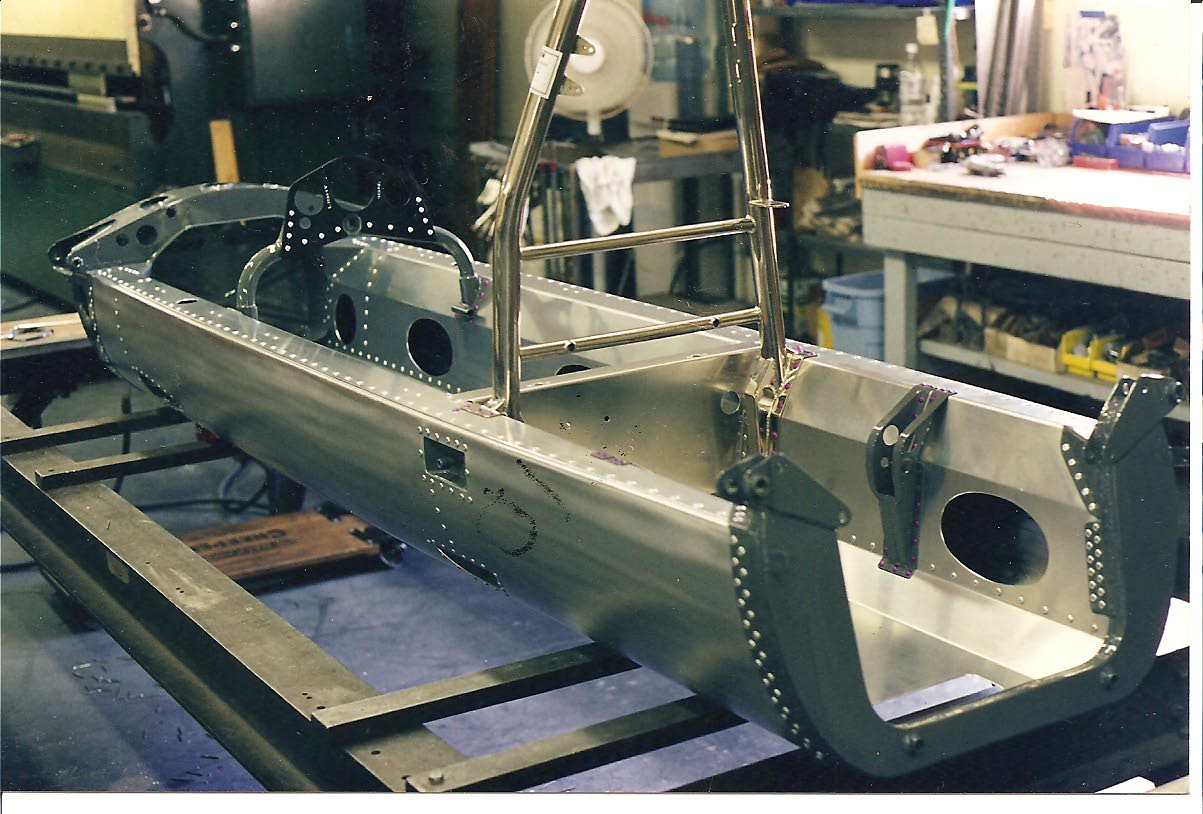

I did think of doing something similar myself, using riveted aluminium monocoque, but adding modern bonding techniques - you should remember that most

aluminium monocoques were only really intended to do one season of racing & tended to get a bit "floppy" in later life, but many of the

principles are as used in aluminium monocoque, or semi-monocoque planes & some of those are 60 years plus old & going strong! Unfortunately

time constraints mean I doubt I'll ever do it, certainly not at present.

PM sent

The 'floppiness' of one of these after a few years is something that worries me, but I was intending on using modern boning techniques as

well... Wheteher or not that would lead to a long lifespan - time will tell!

quote:

Originally posted by paddywil

They were posted more to look at the monocoques than anything else I think...

Just a little different but definately worth a look haha

I always thought the edge devil chassis with an v8 engine and a Auto Union d-type body would sell well if it could be made iva compliant.

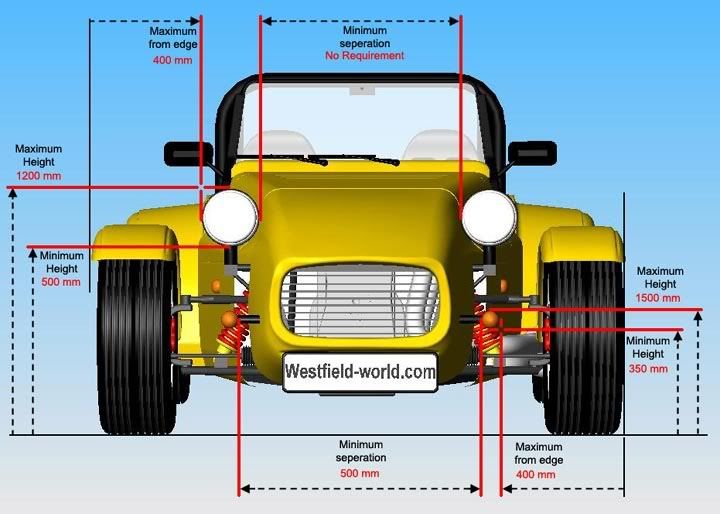

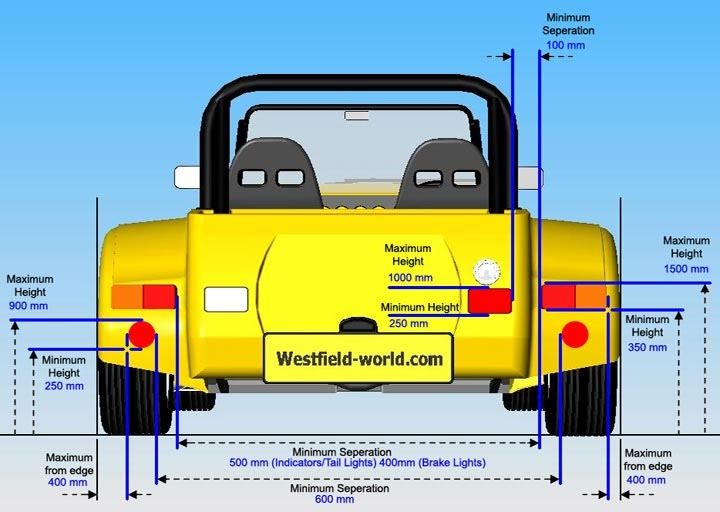

Your first issue is the required light positions

For IVA your going to have to build pods to raise the headlight height

[Edited on 28/10/15 by snapper]

Thanks for the diagram, I don't think its going to be too much of an issue, I'm planning on mounting them in a manner similar to that on the Westfield and gbs zero

quote:

Originally posted by jps

I was briefly confused by this thead - as I saw a 23 replica at Stoneleigh (last year) and the photos below are of 23's, but the 32b is more akin to the 'Haynes Single Seater' idea...

Sam

re "I'd definitely be doing the tub in route-and-fold sandwich panels, though: the design and fabrication of a '60's-style

single-seater tub in this material is really simple." although it's obviously totally "out of period" with regard to the original

type of car, can you explain a little more about this type of construction, it's not something I've ever had much to do with, about the

nearest I got was owning a Pulsar lightweight plane which had a form of honeycomb composite construction - any links to websites for

materials/suppliers or info would be handy

"Funny how many people I've come across through the years who've wanted this sort of single-seater road car. There's got to be an

unexploited market for a simple design, out there... maybe needs to be my next project." - well, I don't do shows anymore, however when I

was doing so if I had a fiver for every picture taken of my car & every person who told me what a great idea it was & brilliant to be

different from all the 7's, etc etc blah blah blah then I'd be a very rich man indeed, as it is fortunately it was never intended to be

anything more than a hobby business & we are now on chassis no.17 (+1 if you count the original car). Many people seem to like the versatility to

be either a single seater or twin depending if "air box" is off or on - something you couldn't do with the 32B without going miles

outside the original dimensions. Much talk has never translated into sales & loads of people talked about the Formula Ford that Ford put on the

road, that exact car is now being sold in the States, but it looks like the price tag is going to be probably around £60k, I can't imagine there

being too many takers, but good luck to the sales team if they can make it fly away.

I think for it to sell it would have to be very, very cheap & as you say, very simple, can't see how you could make a business plan out of

that? I know who has the Edge Devil moulds & chassis now - I think it sold a total of 5 chassis, not all of which are on the road ............. It

does have some major design floors in the aerodynamic department at much over 70Mph, but that could fairly easily be sorted.

Russ

Here is another to add to the reference list - slc nemesis from the USA.

http://superlitecars.com/index.php/cars/nemesis#1728-carlisle_06

No-one has mentioned this

NTDWM and not sure that it is still for sale but it may help?

Haha no worries, I should have put a picture up earlier!

Whichever engine I end up with, it's going to be a straight four, right sounds and it will fit. I'mean starting to think the route and fold

option is going to be the way to go, seems like a pretty simple construction method

quote:

Originally posted by Sam_68

quote:

Originally posted by Ugg10

Remember the beetle has the engine behind it so if you are looking for mid endine then the gearbox will need flipping and so may need things like oil vents/feeders/plugs etc. reworking...

With the Beetle box, you just flip the crownwheel from one side to the other. No need to invert the whole box.

quote:

Originally posted by Ugg10

....have you thought about making the monocoque out of a composite sandwich structure using woven fabric skins (getting the weave directions right between the layers is the key) and a polyeurothane foam core (Rohacel is the gold standard but expensive), this could produce a very light and stiff tub and does not have to be too expensive. Subfrmaes can then be bolted onto the front and rear to hold the oily bits and has the potential, with quick release plugs/lines, to allow quick changes of the rear engine cradle. This was used in the Scultpural Engineering Larini (later the GTM Ballista) and is used in Yacht building.

Personally, I'd go for routed-and-folded pre-manufactured composite sandwich panels, as per the early Lotus F1 carbon tubs and Westfield WiSPER. Much lighter and more consistent quality than trying to 'roll your own' with wet layup. Pre-manufactured panels, such as Cellite, will usually have aluminium or nomex honeycomb cores, which are more suited to automotive use.

Routed-and folded aluminium sandwich panels (as described in Tony Pashley's M/C Engined race car book) are an option too - and certainly better than a single-skin aluminium monocoque.

Out of interest, what is used to adhere the folded panels to each other in the route and fold method?

quote:

Originally posted by Ugg10

Here is another to add to the reference list - slc nemesis from the USA.

http://superlitecars.com/index.php/cars/nemesis#1728-carlisle_06

If anyone wants to know more about building a chassis using the sandwich panels, this makes an interesting read

http://www.tech.plym.ac.uk/sme/acmc/download/chass.pdf

quote:

Originally posted by paddywil

If anyone wants to know more about building a chassis using the sandwich panels, this makes an interesting read

http://www.tech.plym.ac.uk/sme/acmc/download/chass.pdf

As far as I understand this, the structural component of the car would be constructed from the honeycomb, the curved bodywork would then be fabricated

separate, and attached to this structural section...

Both methods have a lot of advantages, so I shall have to have a think. My original plan was to construct the monocoque from just sheet aluminium,

assembled as per the original. If i go down this route, I'm planning on using 'real' rivets on most joints, only using POP rivets on

blind joints.

This would be a fairly easy method of construction, assuming I built a jig to hold the pre-cut panels, then could simply rivet/bond them together.

Im not sure whether the original used the engine as a stressed component, but in this case I don't plan on doing so - I'm thinking of using

a steel tubular structure to hold the engine and support the suspension, which would them bolt to the monocoque

I've made a full size mock up of one of the transverse 'ribs' of the monocoque using a rough set of dimensions, seems fairly satisfactory for driver comfort...

quote:

Originally posted by russbost

It does make interesting reading, but I'm really struggling to see how this method can be used to make the sort of complex curves on something like the 32B - am I missing something here?

quote:

Originally posted by russbost

The original cars were only a monocoque as far as the front bulkhead where the master cylinders were mounted & the rear bulkhead where the engine was bolted in as a stressed member (certainly on later cars with the Cossie DFV, not sure if earlier cars like the 25 & 32B used the engine as a stressed member or if it was carried in some form of subframe with the suspension attached which was the bolted up to the rear of the monocoque?)

Thanks for the pic - very useful to see a tub in its naked state!

Ah! I know what I was forgetting, just how low & bl**dy lethal those old tubs were, Geez, that's barely hip height! I'd forgotten that

they didn't go up around the steering & front suspension bulkheads at all - so, yes, I can see now how that method could be used.

I have to say I'm not happy in a 7 with it's lack of side protection, I would be totally unhappy in a tub like that! & I also

didn't remember the tub extending back to carry the engine & rear suspension, I thought that prior to stressed engines that was all carried

on a subframe - I must be too young!

quote:

Originally posted by russbost

Ah! I know what I was forgetting, just how low & bl**dy lethal those old tubs were, Geez, that's barely hip height! I'd forgotten that they didn't go up around the steering & front suspension bulkheads at all - so, yes, I can see now how that method could be used.)

quote:

Originally posted by russbost

I have to say I'm not happy in a 7 with it's lack of side protection, I would be totally unhappy in a tub like that! & I also didn't remember the tub extending back to carry the engine & rear suspension, I thought that prior to stressed engines that was all carried on a subframe - I must be too young!

"you've potentially got a 9" wide triangular section torsion box"

Eh? How do you compute that one in a single seater??? I'm reasonably slim & sitting down I'm around 16" across the hips, allow

2" each side for some clearance to get a seat, handbrake & gearlever in (still pretty tight), then add your 9" each side & your

single seater is now a minimum of 38"- that's the widest 32B I've ever seen!!!

Not disputing the impact absorbing abilities of foam & fibreglass/aluminium honeycomb, but what would concern me a lot more is that the whole of

my upper body has the protection of .............Errrrr............. a 3mm thick piece of fibreglass or similar!

When I'm sitting in the middle of my Furore I have impact protection to front, rear & both sides, the chassis extends to around my shoulder

height & unless I submarine under the back of a truck (in which case I might be headless! - some would say, no loss!) I'm reasonably safe.

Let's face it, if you connect with a truck whatever you're driving you are going to come off badly. But in a tub such as that pictured

(I'm assuming that anything above the height of the tub would be a thin fibreglass structure largely there for cosmetic & aerodynamic

properties) if you were hit by anything larger than a squirrel whether on 2 wheels or 4, you are going to have a pretty major problem unless it hits

you square on the rear & even then you may find you are now part of the engine!

I'm not terribly risk averse, but would not be in a hurry to ride a motorbike nowadays, I would put a tub such as that in a similar bracket to a

bike as regards safety. I know it might not be "in period" - but then neither is honeycomb construction - but I think I'd want a fair

bit more in terms of a top half of the tub!

"you've potentially got a 9" wide triangular section torsion box"

Eh? How do you compute that one in a single seater??? I'm reasonably slim & sitting down I'm around 16" across the hips, allow

2" each side for some clearance to get a seat, handbrake & gearlever in (still pretty tight), then add your 9" each side & your

single seater is now a minimum of 38"- that's the widest 32B I've ever seen!!!

Not disputing the impact absorbing abilities of foam & fibreglass/aluminium honeycomb, but what would concern me a lot more is that the whole of

my upper body has the protection of .............Errrrr............. a 3mm thick piece of fibreglass or similar!

When I'm sitting in the middle of my Furore I have impact protection to front, rear & both sides, the chassis extends to around my shoulder

height & unless I submarine under the back of a truck (in which case I might be headless! - some would say, no loss!) I'm reasonably safe.

Let's face it, if you connect with a truck whatever you're driving you are going to come off badly. But in a tub such as that pictured

(I'm assuming that anything above the height of the tub would be a thin fibreglass structure largely there for cosmetic & aerodynamic

properties) if you were hit by anything larger than a squirrel whether on 2 wheels or 4, you are going to have a pretty major problem unless it hits

you square on the rear & even then you may find you are now part of the engine!

I'm not terribly risk averse, but would not be in a hurry to ride a motorbike nowadays, I would put a tub such as that in a similar bracket to a

bike as regards safety. I know it might not be "in period" - but then neither is honeycomb construction - but I think I'd want a fair

bit more in terms of a top half of the tub!

quote:

Originally posted by russbost

"you've potentially got a 9" wide triangular section torsion box"

Eh? How do you compute that one in a single seater??? I'm reasonably slim & sitting down I'm around 16" across the hips, allow 2" each side for some clearance to get a seat, handbrake & gearlever in (still pretty tight), then add your 9" each side & your single seater is now a minimum of 38"- that's the widest 32B I've ever seen!!!

quote:

Originally posted by russbost

...what would concern me a lot more is that the whole of my upper body has the protection of .............Errrrr............. a 3mm thick piece of fibreglass or similar!

Im pleased to see how much thought everyone puts into their safety, and mine! I have no expectations of this being a safe car, but I would say that

from a side impact I see there being relatively little protection, although I dont consider a 7 to be safe either!

I think that there could definately be some effort put into front/rear impact protection, but chances are in something this low I'll be going

under whatever i hit

Despite their use on many self build and kit cars at the moment, I'm struggling to find a set of dimensions for mx5 front and rear uprights. Dimensions for either mk1 or 2 would be very useful. Could anyone point me in the right direction please?

quote:

Originally posted by Sam_68

Well, each to their own, and I freely admit that I'm nothing like as risk averse as some of these youngsters who won't go anywhere near a 'Seven' unless it's got a full cage with side intrusion bars...

...but on a 'Seven', you have a 1" steel tube, pretty much touching the side or your torso, that will deform and stay deformed in the event of any significant side impact.

With a sandwich panel tub, you've potentially got a 9" wide triangular section torsion box, made of a material that doesn't permanently deform, but does absorb an immense amount of energy as it progressively collapses (the honeycomb holds everything together, so the carbon/grp skins disintegrate in a very linear, progressive manner in an impact... that's why they make crash boxes out of the stuff for race and supercars).

Nev,

No, no and no, in the strictest terms.

But that is actually a misleading answer; I'm a designer.

I haven't yet built an entire chassis myself, personally, but I have worked with composites and sandwich panels with my own hands, including

rout-and-fold techniques and have been responsible for the design of full chassis.

I'm also an architect, but I've never laid a brick in my entire life...

I don't have a problem with Russ' perspective on safety, and I freely acknowledge that a small single-seater of whatever construction will

be vulnerable on the road.

Similarly. I'm aware of the racing regulations for various classes. As it happens, I've just signed a petition to the RAC objecting against

the changes to requirements for specialist sports cars ROPs.

If you don't want to drive a small single-seater, or an uncaged Seven, that's just fine, and entirely up to you - I'm not going to

force you to!

But, genuinely, in 30 years of driving Sevens and other lightweight kit and sports cars, I've never owned one with a cage, and personally

it doesn't bother me in the slightest. That's my choice too, presumably?

So I know this has been done to death elsewhere, but I want to know what's people's personal thoughts on spherical bearinnags vs nylon bushings, in the context of suspension mounts?

quote:

Originally posted by Sam_68

Lots of interesting stuff

Once I've added a it more to them I will - I'm at exactly that point now, working out the shape for the frame that will accept the front wishbones and coilovers

Sam,

Progressive collapse means permanent deformation, yes, yes, yes. Unless it's a spring.

If you'd had a router anywhere near a panel with ali skins and ali core, you'd know the result. You really haven't done it, have you?

Otherwise, you'd know all about the mess that ensues.

Your knowledge exhibited here re composites goes along with that shown for ali.

As an architectural technician you are probably OK. As a designer with composites, your recommendations are irresponsible to the point of

recklessness.

Anything can be made look good in a design, but properly engineered is something very different. Without knowing the materials hands on, you can never

fully appreciate the limitations and possibilities, and the nuances in manufacturing with them.

Stick with houses, and you won't kill anyone, maybe.

Cheers,

Nev.

I was going to suggest having a look at

http://www.stuart-taylor.co.uk/gallery/f1-67/

I know Ian was working on that when I was building my car in his garage. Nice looking car, suspect it might be £££.

Neville,

G'day, me old cobber.

I'm not going to waste further time or energy on you, since you're obviously intent on trolling. These will be my final words in response to

any post you make on this forum:

No, I've not used a router on ali skinned panels, nor would I try, but on composite skinned panels they work just fine. You're right about

the benefits of working with materials hands-on to get a grasp of their characteristics, and I've done exactly that with small-scale test

fabrications, but...

...one of the advantages of rout-and-fold is that all I have to do is send off the relevant CAD files to a supplier, and they send back panels

accurately cut and routed to my designs for neglible cost, so why on earth would I want to take the risk of ruining an expensive panel by making an

error myself, trying to do a whole tub, less accurately, by hand?

With ali skinned panels, they can be drilled or milled with normal machine tools, but again it wouldn't be something I'd do at home when

there are companies who will do the job for you, much more quickly, accurately and cost-effectively, using CNC controlled machinery.

Progressive collapse does not mean permanent deformation.

It's really very basic materials science, so if you don't understand it (as you either clearly don't, or are pretending not to

in the interests of trolling), then you have no business designing anything, but if it's the former then I suggest that you go away and

learn the meaning of the terms 'elastic deformation', 'plastic deformation', 'yield strength' and 'ultimate

strength'.

Bottom line is that between yield and ultimate failure, materials permanently (plastically) deform.

Steel has quite a large band between yeild and failure, so there is a large possibility of it ending up permanently deformed in a way that can

exacerbate injury - a buckled tube can trap you and the deformed end of a failed tube can cause very nasty penetrative injuries.

Composites, particularly carbon fibre, have a very narrow band between yield and ultimate failure.... they pretty much go from elastic strain straight

to failure. With honeycomb composite panels, the honeycomb tends to provide sufficient support to the skins to ensure that they disintegrate

(not permanently plastically deform) progressively from the point of impact back, absorbing energy as they go.

Hope that helps clarify.

quote:

Originally posted by BenB

I was going to suggest having a look at

http://www.stuart-taylor.co.uk/gallery/f1-67/

I know Ian was working on that when I was building my car in his garage. Nice looking car, suspect it might be £££.

*update*

I've taken the decision to move away from the original monocoque design and instead build a space frame. One of the main reasons for doing this

is to enable easy FEA analysis, as well as solving some of the other design issues I'm facing.

quote:

Originally posted by paddywil

*update*

I've taken the decision to move away from the original monocoque design and instead build a space frame. One of the main reasons for doing this is to enable easy FEA analysis, as well as solving some of the other design issues I'm facing.

quote:

Originally posted by Neville Jones

Sam, when something deforms 'plastically', it deforms permanently. like plastic, and doesn't go back to where it was. Elastic deformation means like a spring, and deforms and goes back where it was. Or that's what I was taught in my first year of my engineering degree!

Get a real life, Sam, and stop pulling the same stupid garbage that I'm told you did on the Oz site.

We could argue semantics on the mechanical properties of materials all day long, but the the members on here are a lot less gullible, and a good deal

smarter than the few who took notice on the other forum. Mild steel can stretch quite a way, but try high carbon and alloyed steel. Same goes for

most other common metals. Please, don't go through them one by one, and show me how wrong I am and right you are. Just plain stupidity.

Make all the sarcastic and nasty comments you want, it still doesn't make your suggested build methods less dangerous.

I'm told that a couple of Signatory Engineers on the Oz forum, made it very clear that a chassis built with your suggested materials and methods,

would never be allowed on the public road. The builders on here made that distinction for themselves.

Thermoplastic honeycomb for a core material, you've got to be joking! Melts when it gets hot! Matey showed me the rest, but it'd be wasting

good forum space to repeat it.

Nev.

[Edited on 3/11/15 by Neville Jones]

Thanks for that nev,

I decided to move to a space frame on the basis of my own research, not from any thing on here...

If we could keep thsee posts on topic I'd be very grateful - this is not the place for those arguments.

Isn't it odd that whenever Sam gets involved in a discussion it seems to end up as a spat!

I could obviously have taken offence to being told that I'm obviously in the wrong business, after all I've only spent virtually all of my

life since age 14, building, racing, designing, working on & being thoroughly involved with cars of all descriptions & such things as road

legality & MoT, SVA/IVA/MSVA tests, so after all what the heck would I know about anything? But, no, life is too short, I had my rant the other

week, which no doubt some of you witnessed or took part in!  So I will now remain calm & placid!

So I will now remain calm & placid!

Sorry Sam, but I'm with Nev regarding plastic deformation etc. & I think if anyone is trolling it is you yourself by splitting hairs &

playing semantics - if something, whether steel or composite, deforms progressively it is almost certainly going to stay permanently deformed (&

permanently damaged/weakened) unless it happens to be a spring! or in a very mild impact; such as of a plastic bumper or something similar even then

although the outer skin may return to shape the foam beneath the skin will be permanently damaged & would not behave in the same way in a future

accident/deformation. In the instance of a tub such as that described, a relatively minor impact could leave the tub unusable as I don't see how

you could ever cut a damaged section out & replace it to give the same strength as the original, so whilst it MIGHT prove relatively strong &

safe it might not prove very economic. With a steel spaceframe or an aluminium monocoque unless the damage was catastrophic the damaged area could

fairly easily be cut out & replaced

When we are talking about a tub constructed as you suggest with the route & fold route I think; one, it is an extremely dangerous process for

someone to undertake with no prior experience, I don't mean that the process is dangerous, I mean the end result would be likely to be dangerous

as it would be almost impossible to know how good a job you had made of the assembly process; & two, unless you had access to CAD, particular

skills in the right areas & understood EXACTLY how to use the process & materials I think it could very easily finish up as a right mess - I

mean, if we stick to an area you actually are familiar with, would you suggest someone with no prior experience should design & build their own

house?

You could possibly say much the same about an aluminium monocoque in that there a whole bunch of unknowns unless you've had experience designing

one previously, however, it's a lot easier to know whether you've made a good job of bonding & rivetting a couple of ali panels together

& a lot less potential for getting it wrong

With a spaceframe there are a whole bunch of designs which can be copied/changed to suit your requirements.

My point about safety is that the design doesn't have to be as lethal as the original "half tubs" were, such as the one you pictured.

The structure could be "wrapped around" to construct an upper half to the monocoque which would not only be a lot stronger, but also a lot

safer, whilst still maintaining the period look & feel of the car, it's not that I have an aversion to risk, but I DO have an aversion to

stupid or unnecessary risk!

To get back to the OP's original questions, I think if going for a period feel then why waste money on anything other than a VW transaxle with a

"flipped" crownwheel, or if you don't mind destroying the period appeal then go for the Audi v6, which I believe has a very short

transaxle, thus keeping it within the original dimensions I would imagine - not speaking from experience here

Perhaps if we could all actually stick to trying to assist the OP with his questions rather than spending our time slagging one another off &

banging the drum in regard to our own personal preference then perhaps that would be beneficial all round?

Thanks

If anyone happen's to know what it takes in either the way on adapter plate or modified bell housing to adapt a zetec engine to either of those

gearboxes id be grateful

The adaptor plate I suspect may be the easier bit, next you need to check what spline the gearbox input shaft has and whether there is a clutch

plate/clutch housing combination that can be used with the engine flywheel, the final part is the diameter of the end of the gearbox input shaft and

whether it will fit with the engine spigot bearing cavity (Zetec is 22mm cavity and 15mm shaft IIRC with the stock pinto spigot bearing). For the Audi

box, if you are lucky you may be able to find a combination of a Audi pressure plate (thickness and diameter) that will fit with a ford zetec/pinto

housing that can work. If not you may be able to get the flywheel drilled to accept the Audi clutch (pressure plate and housing).

Other stuff to think about is where the starter is and whether the bell housing needs modifying to make this fit and whether the release bearing (or

hydraulic release mechanism) will work with the adaptor in place.

Best bet is to gather info on the engine and gearbox options (search for clutch parts on ebay, they often give diameter and spline info) and see if

you can come up with a combo that does the job.

Thatnks! Thats the most useful post so far haha! I'll start searching and see what I can come up with!

I'm no expert on Ford engine/gearbox combinations, but I'm certain the Kent engine has been fitted to the VW transaxle from the beetle &

surely the Kent & Zetec can be fitted to the same Type 9 Ford boxes? It would therefore seem exceedingly likely that the Zetec could be fitted to

the VW transaxle with the same combination of clutch & possibly flywheel? Personally I've always felt the Zetec was very over-rated &

feel the Duratec is a much better bet, would have thought if you could fit one then the other would fit

In the VW camp I'm sure the 2.0 injected Golf lump both NA & turboed has been fitted to the beetle transaxle which might suggest that VW/Audi

engines MAY be somewhat interchangeable, but no idea if that extends to the V6 engine/box being transposable with any other VW/Audi lumps let alone

Fords

If it was me I would look around the internet for what HAS been done before & how much difficulty it involves, but unless you particularly feel

the need for something newer than the beetle transaxle (or transporter if more power is involved) then that seems the most obvious route. If, for

whatever reason, you opted for the much newer Audi transaxle (is that available as a 6 speed anyone?) then surely easiest & most economic route

would be to go for the complete V6 or V8 package from Audi complete with all the anciliaries etc. rather than attempting to re-invent the wheel

There is another option of course which would be to go for the 5cyl Audi turbo & transaxle from something like the old Audi 100, dirt cheap, loads

of power but very heavy - they used this setup in the back of the Edge Devil, but I believe the car weighed around 750kg all up, probably not quite

the svelte result you would be hoping for

quote:

Originally posted by Neville Jones

Get a real life, Sam, and stop pulling the same stupid garbage that I'm told you did on the Oz site.

We could argue semantics on the mechanical properties of materials all day long, but the the members on here are a lot less gullible, and a good deal smarter than the few who took notice on the other forum. Mild steel can stretch quite a way, but try high carbon and alloyed steel. Same goes for most other common metals. Please, don't go through them one by one, and show me how wrong I am and right you are. Just plain stupidity.

Make all the sarcastic and nasty comments you want, it still doesn't make your suggested build methods less dangerous.

I'm told that a couple of Signatory Engineers on the Oz forum, made it very clear that a chassis built with your suggested materials and methods, would never be allowed on the public road. The builders on here made that distinction for themselves.

Thermoplastic honeycomb for a core material, you've got to be joking! Melts when it gets hot! Matey showed me the rest, but it'd be wasting good forum space to repeat it.

Nev.

[Edited on 3/11/15 by Neville Jones]

Sorry if this is off-topic, Paddy, but there are misconceptions being promoted here that are far from splitting hairs... we're talking very

basic, fundamental materials science and it's quite scary that they are apparently being misunderstood by someone who has designed and built

a car.

quote:

Originally posted by russbost....if something, whether steel or composite, deforms progressively it is almost certainly going to stay permanently deformed (& permanently damaged/weakened) unless it happens to be a spring!

quote:

Originally posted by russbost...In the instance of a tub such as that described, a relatively minor impact could leave the tub unusable as I don't see how you could ever cut a damaged section out & replace it to give the same strength as the original, so whilst it MIGHT prove relatively strong & safe it might not prove very economic. With a steel spaceframe or an aluminium monocoque unless the damage was catastrophic the damaged area could fairly easily be cut out & replaced

quote:

Originally posted by russbost...When we are talking about a tub constructed as you suggest with the route & fold route I think; one, it is an extremely dangerous process for someone to undertake with no prior experience, I don't mean that the process is dangerous, I mean the end result would be likely to be dangerous as it would be almost impossible to know how good a job you had made of the assembly process; & two, unless you had access to CAD, particular skills in the right areas & understood EXACTLY how to use the process & materials I think it could very easily finish up as a right mess...

Gahhhhhhhhhh!

Which part of stop arguing & stay on topic do you not understand!

There are about 1001 things wrong with that last post which I am not going to respond to, I would suggest that Nev doesn't either

Sam, could you PLEASE make your posts less deliberately insulting, if you want to disagree with something someone has said, fine, but do it in a way

that doesn't include words like inept & idiot. It would appear to me that you may have great qualifications & can talk the talk, there

doesn't appear to be much evidence of walking the walk, that's not intended to be insulting, just how I am seeing what gets said

This is supposed to be a forum for people from all walks of life who can contribute in areas where they have knowledge &, one would hope,

practical skills. I've had tons of great advice regarding stuff like household plumbing & electrics from people with vastly more knowledge

than me which has been extremely useful, I would freely admit that I don't have much experience of composites, hence why I ask questions. I very

rarely disagree publicly with anyone on the forum, but you speak to people as tho' they are morons with no knowledge of what they are talking

about simply by taking a sentence & disseminating it into soundbites which then don't mean what the poster meant to say!

I would repectfully request that if you haven't got anything helpful to say in respect of what the OP has asked then it might be better to say

nothing ................

Right, I would appreciate it if we could have no more discussion about this argument, it's time to move on. For the sake of this build, the

argument has been useful, but from this point onwards, let's assume a few things:

I am going to use a spaceframe for this build

As much I would like this to be a replica, I am more concerned with the economics of this than historical accuracy.

I may in the future attempt a monocoque, but that's up in the air at the moment

What I would like input on is people's preference for fibreglass vs aluminium bodywork - going down the space frame root will require a large

amount of body work to achieve the desired shape... I have experience of both making Ali panels and making moulds for fibre glass, so that's not

the issue, I simply want to know what people in my place would choose.

I WILL STICK TO THE SUBJECT IN HAND :-)

So.......

There are a couple of interesting threads that I hope you will have seen that might help in making the choice of skin -

Aluminium re-skin of a triumph GT6 - http://www.locostbuilders.co.uk/viewthread.php?tid=178173

Some of the craft in this piece of work is truly outstanding, IIRC there are some pictures of this guys trials car that was again aluminium skinned

that may be useful

Fibreglass build of a single seater car should buck and moulding processes - http://www.locostbuilders.co.uk/viewthread.php?tid=194783

Also T89 design of a single seater - more modern/formula type design but process may be useful -

http://www.locostbuilders.co.uk/viewthread.php?tid=195128

I suspect that the fibreglass route (depending on your skills with an English wheel) may be quicker and can cope with more complex shapes and you have

the chance of making another if your moulds are built and finished well but aluminium, particularly if left polished could be stunning to look at and

more authentic.

Tiger does a version of their Six (Seven?) car with an aluminium body if that is of interest - http://www.tigerracing.com/rs6.php

and......

I DID STICK TO THE SUBJECT !!!!!

quote:

Originally posted by paddywil

Right, I would appreciate it if we could have no more discussion about this argument, it's time to move on. For the sake of this build, the argument has been useful, but from this point onwards, let's assume a few things:

I am going to use a spaceframe for this build

As much I would like this to be a replica, I am more concerned with the economics of this than historical accuracy.

I may in the future attempt a monocoque, but that's up in the air at the moment

What I would like input on is people's preference for fibreglass vs aluminium bodywork - going down the space frame root will require a large amount of body work to achieve the desired shape... I have experience of both making Ali panels and making moulds for fibre glass, so that's not the issue, I simply want to know what people in my place would choose.

quote:

Originally posted by russbost

Gahhhhhhhhhh!

Which part of stop arguing & stay on topic do you not understand!

There are about 1001 things wrong with that last post which I am not going to respond to, I would suggest that Nev doesn't either

................

By the mid-60's, upper bodywork was in GRP, so that would be the 'authentic' solution and I'd have thought much easier than alloy

for some of the shapes? Also rather more tolerant of small knocks and scrapes?

The sill panels of the 'tub' were aluminium and, being single curvature, would be pretty easy to from from ali anyway. If you're using

a spaceframe, you'll be able to see these panels from inside the cockpit, so bare ali might look nicer than the rough face of a GRP panel?

To add to the bodywork building scenario, when I did the original body for the Furore I was only ever intending building one car - for myself - it was

never intended to go into production!

I built the panels by first making a basic frame in 1/2" square tube to the size & shape of what I was trying to produce, shapes a lot more

complex than the Lotus 25 or 32, I then formed 1.2mm (IIRC) ali sheet around the steel to get the basic shape, where complex curves were involved I

just split the ali as necessary & folded it to shape, you can get within maybe 3mm or so like that & then just used filler with some chopped

fibreglass in to get it to the correct finished shape. Once at that stage the panel is ready for primer & paint. In a few areas, like the curve in

front of the screen, I went straight for fibreglass over the basic frame, supported with thin wire mesh during the forming process

The panels thus formed were still on the car several years later when it was sold, with very little deterioration, just one or 2 tiny cracks where I

should have put more support under the filler.

Nev, I'm slightly confused by the method you are describing, I've seen that method used to make bucks, but surely if you're making

finished bodywork aren't you going to have a ton of filling & rubbing down after glassing up over the packing tape stage or am I (as usual)

completely missing something?

Going back to the safety aspect, you can very easily extend the spaceframe up around the upper half of the tub which will not only increase stifffness

(at a very small weight cost), but will also greatly increase driver safety - pretty obvious that something like this is never going to be as safe as

an ordinary tintop, but I don't have a built in death wish & see no point in making it any easier to get flattened than necessary.

The upper "half" of the body could still be finished in fibreglass to get the required shapes, but if doing a one-off, much easier to make

this all part of the structure of the vehicle, just cut a "bonnet" aperture for access to steering, suspension, brakes, battery, cooling

etc.

Russ,

The amount of time and effort put into the fairness of that last csm layer, dictates how much filling and fairing is done on the final article.

Yes, the final surface will need a complete all over skim then sanding, but the choice of material makes a significant contribution. CSM will need a

good deal of elbow grease.

The moth hull was a 4x4 twill,(carbon in this case, but glass is easily had) which draped really easily over the plug. The filler was epoxy/balloons,

and when finished and sanded, prior to paint, very little of the balloons was left. Mostly small patches between the weave. This is countered by the

amount of resin that needs to be applied when using cloth over foam in a mould. With what I built, you just paint on some epoxy on the inside,(after

thorough dewaxing and sanding, before HE gets picky and pedantic) then in goes the foam then a layer of carbon over that. I should have taken some

pics, but this sort of thing is fairly routinely done around here, for one-offs, for many years, and isn't seen as out of the ordinary.

With the Lotus32 shape, the biggest problem in putting the car on the road will be headlight positions. Mounted up high, just inside the wings, might

work. I've seen that done before.

Cheers,

Nev.

Thanks for the tips and advice.

Previously I've made GRP panels by making bucks from MDF, stacking them and continuing on from there... I think as there is a strong likely hood

of doing more that one run of panels, I'll probably do the same again, but have the panels CNC milled, rather than forming them by hand...

Despite that, the aesthetics of an aluminium bottom section are quite tempting...

As russ said though, I'm looking at bring the space frame higher up, then having single piece side panels rather the removable top at the front,

instead making removable panels where required.

As this is going to be a road car I may stretch to paneling the inside of the tub in ali purely for aesthetic reasons.

quote:

Originally posted by Neville Jones

Russ,

The amount of time and effort put into the fairness of that last csm layer, dictates how much filling and fairing is done on the final article.

Yes, the final surface will need a complete all over skim then sanding, but the choice of material makes a significant contribution. CSM will need a good deal of elbow grease.

The moth hull was a 4x4 twill,(carbon in this case, but glass is easily had) which draped really easily over the plug. The filler was epoxy/balloons, and when finished and sanded, prior to paint, very little of the balloons was left. Mostly small patches between the weave. This is countered by the amount of resin that needs to be applied when using cloth over foam in a mould. With what I built, you just paint on some epoxy on the inside,(after thorough dewaxing and sanding, before HE gets picky and pedantic) then in goes the foam then a layer of carbon over that. I should have taken some pics, but this sort of thing is fairly routinely done around here, for one-offs, for many years, and isn't seen as out of the ordinary.

With the Lotus32 shape, the biggest problem in putting the car on the road will be headlight positions. Mounted up high, just inside the wings, might work. I've seen that done before.

Cheers,

Nev.

No, I described a method to make a one-off on a male mould-plug.

As it happened, the finished hull was given a high gloss finish, and a mould was taken off it.

The plug could easily have been given a high finish and a mould taken, then the hull built in the mould.

The end result was a usable plug, a finished hull, and a mould. But one-offs are built like this regularly.

Another method is to make up a timber former, with transverse stations and longitudinal battens, cover it with core foam, then laminate over that to

get the outer skin. Turn it over and put in the inner layer. Many ways of doing one-off composite work, other than going through all the hassle of

high gloss perfect plugs, then moulds, then moulding from the mould.

If you only want one, then you go about it the quickest and most economical way.

Cheers,

Nev.