Since getting through the IVA test in August 2013 the car had always needed setting up properly. I'd just ticked over the 1,000 mile marker on the car so decided that now would be as good a time as any to get everything pointing in the right direction.

I chose to take my car to Procomp Motorsport in Birmingham. Father and son team, Ivan and Matt, have worked in the kit-car industry for many years and compete in the Locost Race series; racing their own car and providing support for many other racers.

I feel I should point out that, as the name of the car suggests (Locost) that this was never a big-budget build by the creator of my car. The front wishbones are 'static' and made to a spec, the chassis is home-made (box section welded together by a chap in Lincolnshire in his garage) and most significantly the car runs a big, heavy Atlas rear axle as opposed to having the independent rear suspension of the factory-built cars. (There is an argument that live-axle cars are better on tracks than IRS but we'll save that for a later date).

After the car was loaded up on to the trailer I made the 200 mile round-trip to Procomp. Upon arriving the car is wheeled into the garage and all 4 shock absorbers are removed. They are then put on a shock-dyno and measured for rebound and compression on each 'click' setting for consistency.

My car runs GAZ Gold shock absorbers which is not expensive suspension by any stretch of the imagination. The shock dyno, aside from highlighting any physical issues with the shocks, also checks the pairing of the adjustment i.e. That 4 clicks on the LF shock is the same stiffness as 4 clicks on the RF shock.

Once all 4 shock absorbers had been put through their paces on the dyno, each spring was then tested for lb-age on a press.

Once all the suspension is built back up they move on to the height and then corner-weighting of the car.

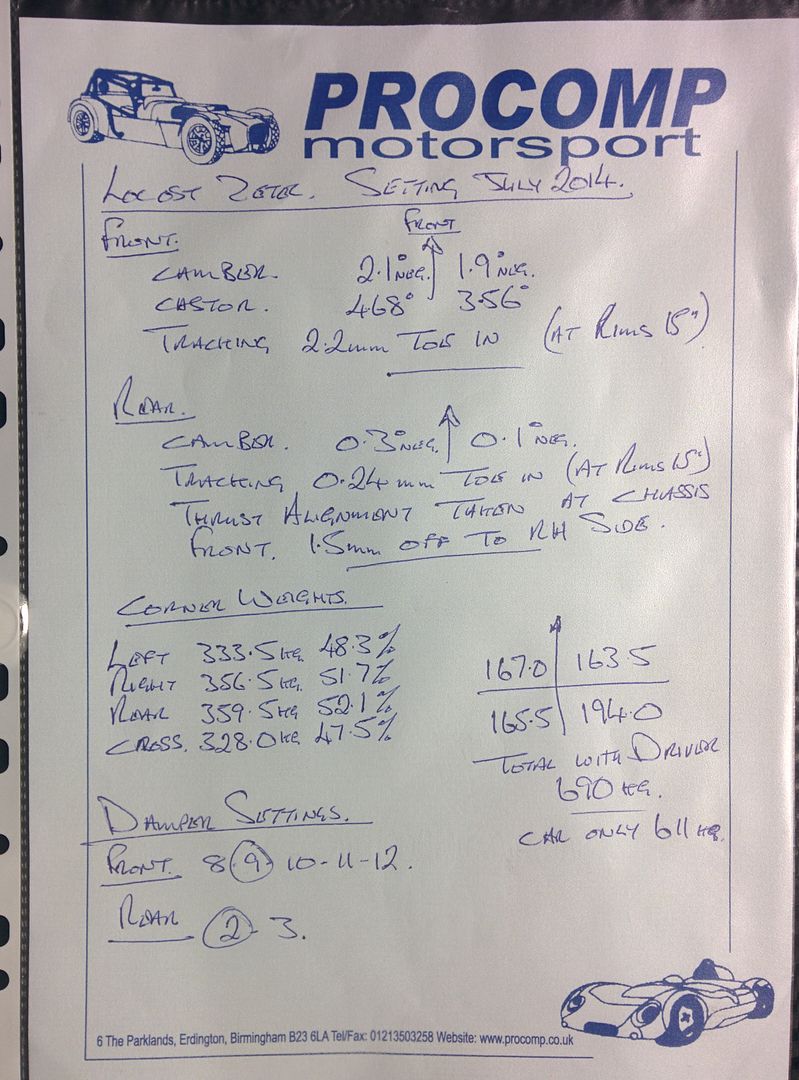

The end results, without me in the car were:

They then move on to the camber, castor and toe adjustments - however as noted already most of mine is fixed so it was more of a case of adjusting what we can and checking to make sure none of the other readings are massively out.

Although I have a solid rear beam, there are many cases of these distorting when extra mounting brackets are welded on. In my case, due to having the larger, Atlas rear axle instead of the English axle, mine was within a couple of mm of being straight.

Once the settings have been checked and OK'd, the car is then corner-weighted against incase any of the adjustments have altered anything.

After that, there's some complex testing in order to assess the best shock absorber stiffness setting

The end result can be seen below:

The guys started at 10am and I didn't leave until gone 7pm, and all for a fixed price.

My car was found to have no dangerous, or worrying issues however a couple of points were noted:

1 - We ran out of camber adjustment on the RF so ideally the wishbones needs a few mm shaving off in order to obtain another turn.

2 - The RF wishbone has less castor than the LF but not enough to cause me any issues on the road.

3 - My rear springs are 160lb and ideally could do with being around 120lb due to the weight of the rear axle. (one for the shopping list)

My car isn't an out and out track car and spends most of it's time on the road, I also live in Yorkshire and, despite what the roads looked like on the Tour-De-France route we probably have some of the worst-maintained roads in the UK.

I didn't get chance to get behind the wheel of the car yesterday so have no comparisons to make yet, I just wanted to document my day whilst it was still fresh in my mind.