Rose joint instead of normal ball joint

FERRARIST - 27/8/14 at 08:45 PM

I'm considering different options for my front lower wishbone, and because it's my first build i rather prefer to ask maybe silly questions

than risk my own safety.

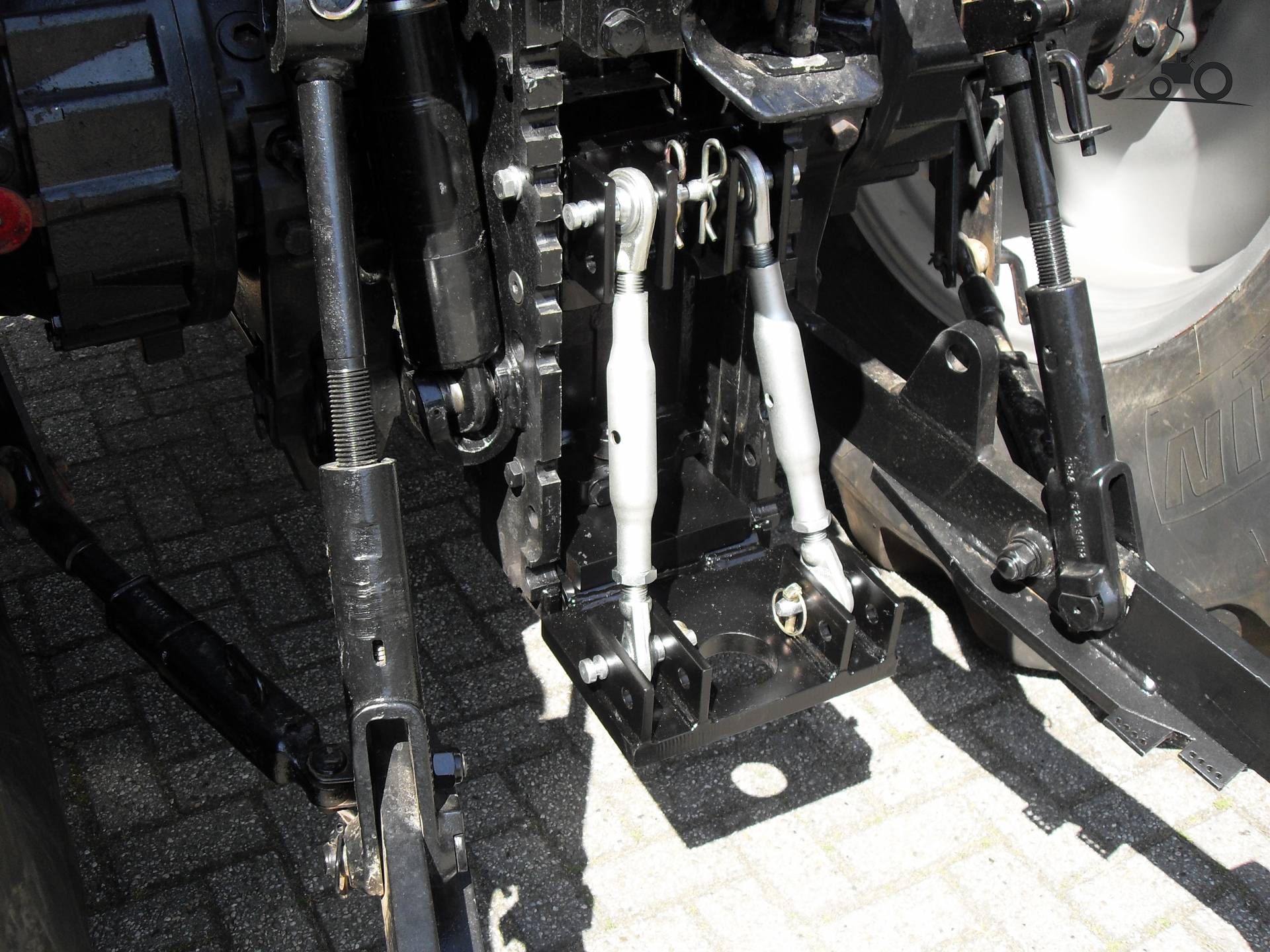

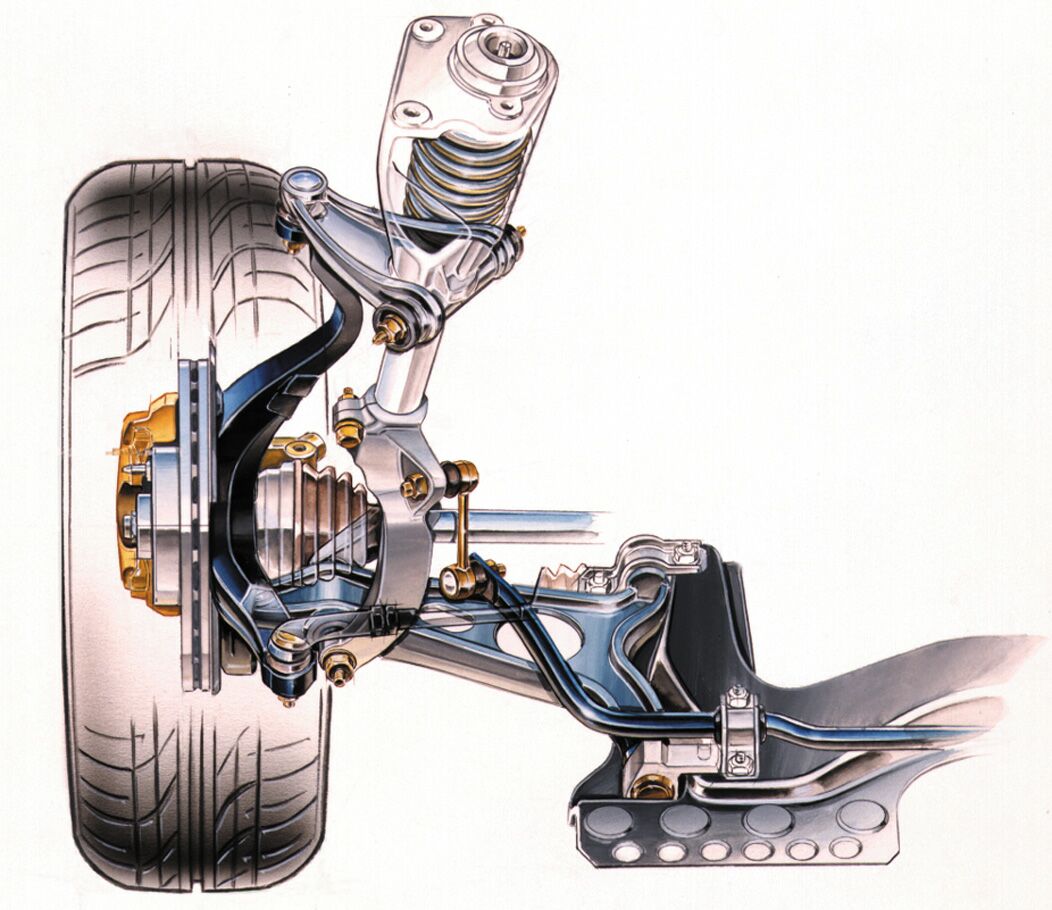

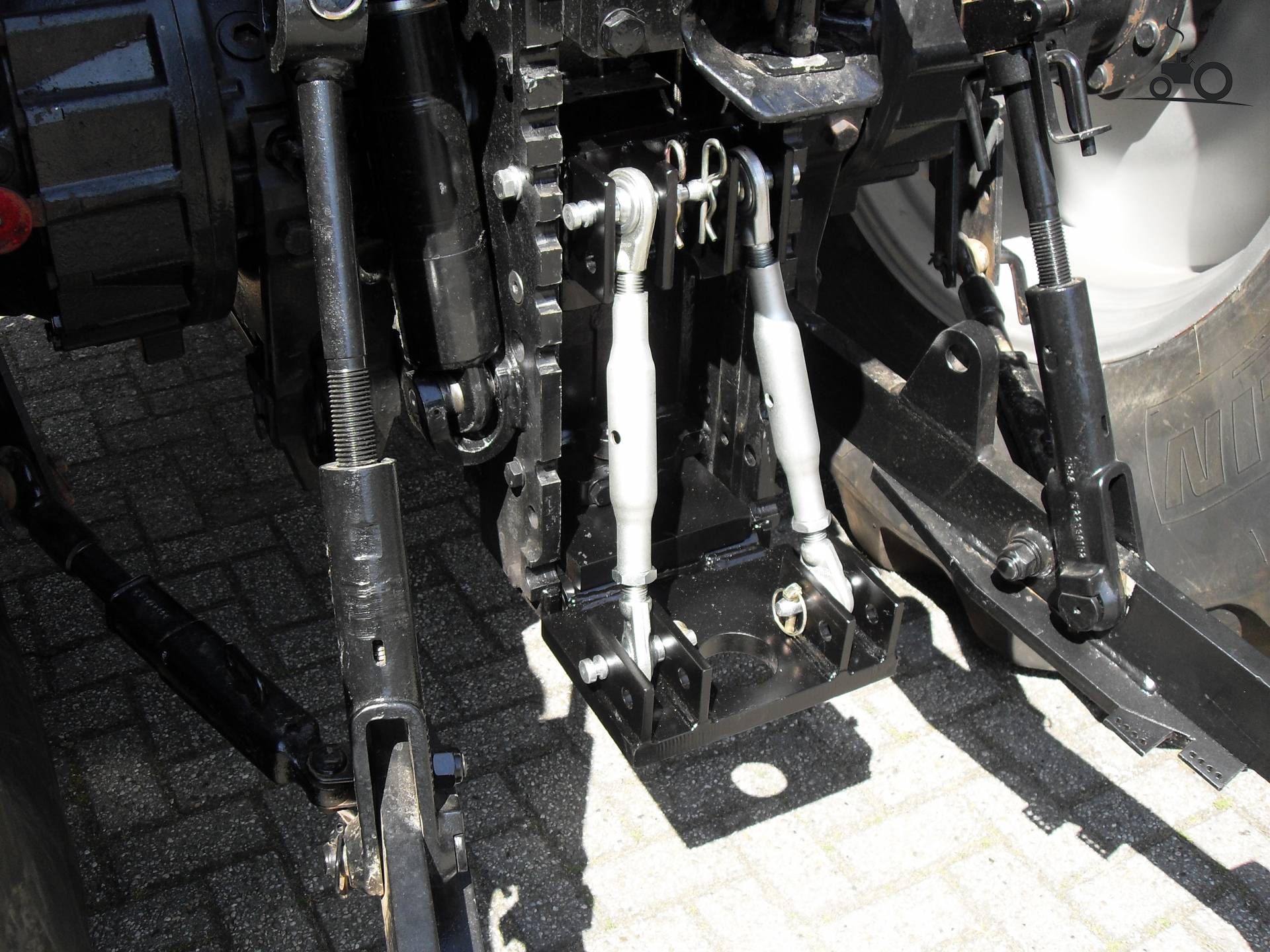

I'm using shorten version of the upright pictured below just for this example(used one is shorter)

My question is will 20mm rose joint be strong enough to sustain weight in the front? I know that rose joints works in different direction, but i saw

many applications like this. I will redrill upright hole to 20mm as well and strongest bolt used.

Lower arm is 48cm long, damper mounting point is 8cm away from the rose joint and there will be enough play(up and down) so i have no worry about.

Seamless 26x3mm tube for wishbone, my plans is total weight of 660kg.

Sam_68 - 27/8/14 at 09:23 PM

It will probably be strong enough, but it's not a good or elegant solution.

Why are you not able to use a ball joint?

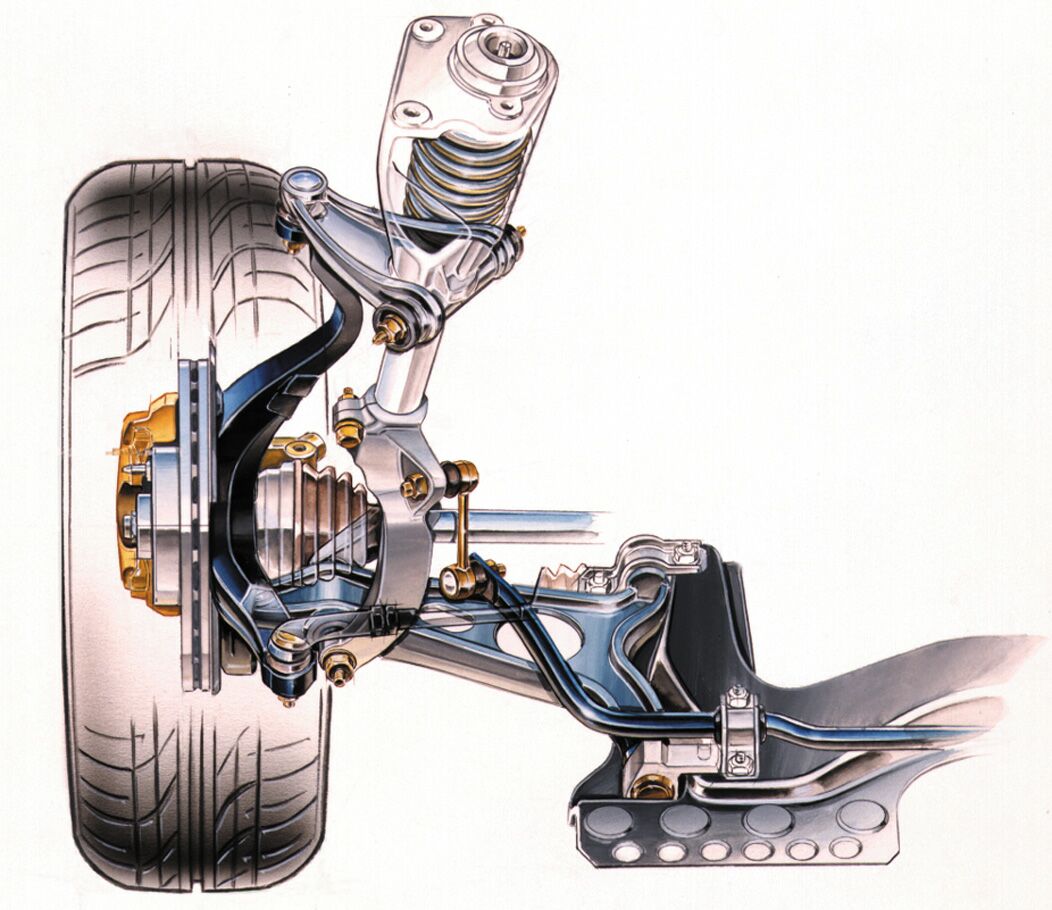

If there's no suitable ball joint available, have you considered a spherical bearing in a fixed, machined housing for the heavily loaded bottom

wishbone, and use a Rose joint for camber adjustment on your lightly-loaded top wishbone?

drt - 28/8/14 at 03:58 AM

agreed,

using rosejoint in that manner is a sin.

Would never pas scrutineering at FS.

What vehicle is it from ?

Otherwise...

You can readily get the 'maxi' ball joint dimensions.

(maxi balljoint -> used in most locosts)

So if you have acces to a lathe...

FERRARIST - 28/8/14 at 05:27 AM

There few reason why using such solution is preferable for me.

First is that sourcing right parts and services to make locost in my country is a little nightmare, i'm living in the 5th largest city here and

believe me or not nearest pipe bender that can bend 50x4mm seamless pipe is 70km away from here.

Second is that because of the first reason i prefer to use parts from cars that i know very well and if i mess a part i just scrap it and take

another........

I know about maxi joint is used a lot but my upright hole is bigger than it and it's for a joint cone working in a opposite direction.

Car will be used for trackday only with our laws here is't impossible to make it road legal. i'm using mostly Alfa Romeo 156-166 parts for

the reason above.

Read a lot of good or bad opinions about maxi joints here and in US locost forums, and that's why i'm in doubt which joint will be strong

enough to work in pull-out application like this.

Hope you understand.

phelpsa - 28/8/14 at 07:53 AM

quote:

Originally posted by drt

agreed,

using rosejoint in that manner is a sin.

Would never pas scrutineering at FS.

What vehicle is it from ?

Otherwise...

You can readily get the 'maxi' ball joint dimensions.

(maxi balljoint -> used in most locosts)

So if you have acces to a lathe...

It would pass scrutineering at FS, as many cars this year, last year and the many years before have done. There is nothing inherently wrong with the

arrangement if it achieves the design goals set out.

My preference would be to use a ball joint from something that was designed to be loaded in that direction however (ie not from McPhereson Strut).

[Edited on 28-8-14 by phelpsa]

motorcycle_mayhem - 28/8/14 at 08:02 AM

Sylva were quite happy to use a rose joint, as you picture, in single shear, at the bottom of their modified Escort strut. I've seen this on

their Riot device. They were also quite happy to use a Fiesta front upright, modified, inverted, at the rear.

Just do it and see what happens?

mark chandler - 28/8/14 at 08:15 AM

If your shock absorber landed on the hub I do not see any issue, as it is landing on the lower bone this will be taking the whole cars weight.

If you do this make sure you have a big washers incase it fails.

Regards Mark

pewe - 28/8/14 at 09:18 AM

IIRC the F27 uses a Ford Transit steering ball-joint.

Seems to do the job and to my mind safer than a rose-joint as less likely to detach from the centre.

Also the steering ball-joint is enclosed and was designed for that type of application.

Cheers, Pewe10

bbwales - 28/8/14 at 09:51 AM

Having had a Rosejoint shear on my rear wishbone as I was going down a French motorway I steer well clear of using them on wishbones, 3 Pirouettes and

the rear end hitting the central crash barriers tend to do that.

nick205 - 28/8/14 at 02:56 PM

Surely a spherical bearing pressed into the lower wishbone is a better solution. A more fail safe solution considering the loading on the bearing

itself in it's weakest plane. It also removes the shear loading on the rod end shank.

prawnabie - 28/8/14 at 04:00 PM

quote:

Originally posted by bbwales

Having had a Rosejoint shear on my rear wishbone as I was going down a French motorway I steer well clear of using them on wishbones, 3 Pirouettes and

the rear end hitting the central crash barriers tend to do that.

I always thought your quick release mech on the steering whel failed? Must be old age!

Def old age - I think I mixed you up with Bizzle!

[Edited on 28/8/14 by prawnabie]

bbwales - 28/8/14 at 04:20 PM

Yep a case of mistaken identity, definitely a rose joint in my case.

FERRARIST - 28/8/14 at 05:54 PM

Thanks for your opinions people, i'll stick with modified kind of front lower wishbones that i used on my mid-engined Alfa 156......brutal and

ugly solution, but i use balljoint that originally fits into this upright, and on later stage when project completed i may try better

solution......

Just completed chassis frame, both upper wishbones, bought alloy rad, set of wilwood pedals and 4 GAZ dampers, and i'm eager to complete it in

few months......

Is 85kg good achievement for chassis frame weight??????

Sam_68 - 28/8/14 at 06:38 PM

quote:

Originally posted by FERRARIST

Is 85kg good achievement for chassis frame weight??????

It's pretty unexceptional, for a 'Seven'-type spaceframe. Depending on your drivetrain, you're still on target for your 660kg

all-up weight, though: the last 'Seven' design I worked on had a chassis about 16 kilos lighter than that, and an all-up weight (with Ford

Duratec engine) of about 575kg.

drt - 28/8/14 at 07:48 PM

I invite you to read 'pat's corner'

http://www.formulastudent.de/fsg/pr/news/details/article/pats-seven-deadly-sins-of-fs-design/

Fs cars with that setup have always been excluded in the design competition.

It is inherently wrong. And even if you are self confident and fem up the saft, stating it will hold.

The ball will always come out the socket sooner or later...

But the silver model on this vehicle might do the trick

quote:

Originally posted by phelpsa

quote:

Originally posted by drt

agreed,

using rosejoint in that manner is a sin.

Would never pas scrutineering at FS.

What vehicle is it from ?

Otherwise...

You can readily get the 'maxi' ball joint dimensions.

(maxi balljoint -> used in most locosts)

So if you have acces to a lathe...

It would pass scrutineering at FS, as many cars this year, last year and the many years before have done. There is nothing inherently wrong with the

arrangement if it achieves the design goals set out.

My preference would be to use a ball joint from something that was designed to be loaded in that direction however (ie not from McPhereson Strut).

[Edited on 28-8-14 by phelpsa]

FERRARIST - 28/8/14 at 08:34 PM

quote:

Originally posted by Sam_68

quote:

Originally posted by FERRARIST

Is 85kg good achievement for chassis frame weight??????

It's pretty unexceptional, for a 'Seven'-type spaceframe. Depending on your drivetrain, you're still on target for your 660kg

all-up weight, though: the last 'Seven' design I worked on had a chassis about 16 kilos lighter than that, and an all-up weight (with Ford

Duratec engine) of about 575kg.

Well it's my newby build, and second overall in my country - owner of the first disintegrate spectaculary in pieces on some time-attack

event.......that's why for my first build i prefer more weight and safety........

quote:

Originally posted by drt

I invite you to read 'pat's corner'

http://www.formulastudent.de/fsg/pr/news/details/article/pats-seven-deadly-sins-of-fs-design/

Well it's a nice read, months ago while browsing for info i found same link, and here is why i asking for more experience....

[Edited on 28/8/14 by FERRARIST]

Sam_68 - 28/8/14 at 09:07 PM

quote:

Originally posted by FERRARIST

Well it's my newby build, and second overall in my country

Yes, I apologise. My wording came across as overly critical, I think.

85kg is certainly not grossly overweight, either.

drt - 29/8/14 at 12:13 AM

Hi there again

The alfa 156,166 did have a mcpherson/double guiding arms hybrid front suspension right ?

Do you see it possible to use the OEM lower balljoint ?.

http://www.alfaworkshop.co.uk/alfa_lower_156_wishbone.shtml

Here you can get the balljoint seperately;

LANCIA Y10 (156) 1.1 PETROL BALL JOINT SS124 5743

FERRARIST - 29/8/14 at 06:20 AM

quote:

Originally posted by drt

Hi there again

The alfa 156,166 did have a mcpherson/double guiding arms hybrid front suspension right ?

Do you see it possible to use the OEM lower balljoint ?.

http://www.alfaworkshop.co.uk/alfa_lower_156_wishbone.shtml

Well it may sound insane for all of you, but i used same OEM balljoint cutted and rewelded to tubular wishbones on my 156's.....when you look at

below pictures you maybe ask how ball joint handles welding heat - there is a way to "recycle" same ball joint, as i said i may sound insane

for you, but it's common practice here.

And this wishbone survive 2 years on a 1250kg car with front V6 engine, survive 2 more years after i moved engine on rear end of the car.......and

i'm running 2506418 michelin full slicks.......as you may see from the clip......

http://youtu.be/D2ON21ZAFaU?list=UUKdh-yZtLNdHCN5FL25tNOw

Than's why i can use same ball joint, but i need to search for alternatives......

[Edited on 29/8/14 by FERRARIST]

[Edited on 29/8/14 by FERRARIST]

[Edited on 29/8/14 by FERRARIST]

phelpsa - 29/8/14 at 05:10 PM

quote:

Originally posted by drt

I invite you to read 'pat's corner'

http://www.formulastudent.de/fsg/pr/news/details/article/pats-seven-deadly-sins-of-fs-design/

Fs cars with that setup have always been excluded in the design competition.

It is inherently wrong. And even if you are self confident and fem up the saft, stating it will hold.

The ball will always come out the socket sooner or later...

There is a difference between Pat and other design judges marking you down in the design competition and it failing scrutineering. I attended three

competitions in three countries this year and at each one there were cars running with that arrangement. None of them did well but none of them had a

dramatic suspension failure either.

There ball will not 'always come out' as long as you adhere to the maximum axial load of the bearing.

[Edited on 29-8-14 by phelpsa]

coyoteboy - 29/8/14 at 05:34 PM

It's still bad design if the correct method is available to be used. Just because you CAN ride an elephant to work in the morning, doesn't

mean it's going to like it, not potentially going to kill you at some point and purely from some principle - just wrong. I've seen quite a

few REIB failures at the few FS events I've been to, even on bulky ones. The reason they are marked harshly is because it's a design event

and it's a bad design.

The other problem you have there is the fastener will be in single shear - another bad idea, but we're not entering an FS competition so

it's your call.

[Edited on 29/8/14 by coyoteboy]

Sam_68 - 29/8/14 at 05:55 PM

quote:

Originally posted by motorcycle_mayhem

Sylva were quite happy to use a rose joint, as you picture, in single shear, at the bottom of their modified Escort strut.

It's possibly worth picking up on this comment, in that since Sylva use top rocking arm suspension, the bottom arm is very lightly loaded in

comparison: it's not reacting the weight of the car via the coilover, when you hit a bump. It's just acting as a track control arm (loading

the Rose joint axially, in the 'correct' direction) and taking a share of the fore-aft loads from braking, in a direction which, while

it's trying to bend the shank of the Rose joint, isn't trying to push the ball out.

It's perfectly fine in the Sylva application; it's very questionable in the OP's application.

Ball joint would be correct. Spherical bearing in a machined housing on the wishbone (inserted from the correct direction to make it

'failsafe' by the machined housing retaining the ball if it presses out, and secured in place by a circlip) would be second choice. Rose

joint as suggested would be a last resort, even if correctly sized.

drt - 31/8/14 at 02:30 AM

Well it may sound insane for all of you, but i used same OEM balljoint cutted and rewelded to tubular wishbones on my 156's.....when you look at

below pictures you maybe ask how ball joint handles welding heat - there is a way to "recycle" same ball joint, as i said i may sound insane

for you, but it's common practice here.

And this wishbone survive 2 years on a 1250kg car with front V6 engine, survive 2 more years after i moved engine on rear end of the car.......and

i'm running 2506418 michelin full slicks.......as you may see from the clip......

http://youtu.be/D2ON21ZAFaU?list=UUKdh-yZtLNdHCN5FL25tNOw

Than's why i can use same ball joint, but i need to search for alternatives......

[Edited on 29/8/14 by FERRARIST]

[Edited on 29/8/14 by FERRARIST]

[Edited on 29/8/14 by FERRARIST]

SAM68 has the answer

As you wat to recycle most of your current racing car I understand?

And you have a much 'stronger' top balljoint... (still not ideal)

(isn't that a transit drag link btw ?)

-> put the spring on the top arm.

Maybe a cantilever like on a fury (among others)

(maybe strengthen threaded shaft)

Or... just think outside the box...

Use a real old fashioned King pin.

Like on this Cooper f3 car

So drilling out your upright and use a shaft sat in nylon or... as bush.

Don't take me up on this, as I know that it is bad in so many ways.

FERRARIST - 31/8/14 at 10:52 AM

quote:

Originally posted by drt

And you have a much 'stronger' top balljoint... (still not ideal)

(isn't that a transit drag link btw ?)

No, it's Land Rover Discovery rod end.....

P/N QFS000010 QFS100060