Bolt on hubs/ bearings

GRRR - 17/3/20 at 12:25 PM

Hi all,

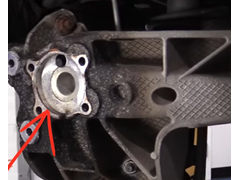

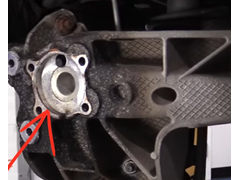

I'm working on a design for uprights and currently using BMW Mini bolt on hub and bearing assembly. The bearing/hub (seems common in all bolt on

hubs) has a circular feature that locates onto a large hole in the Mini trailing arm, with the hub bolts just proving clamping force. Any thoughts on

what sort of fit that hub cylindrical feature to trailing arm hole would be? I'm thinking a clearance fit, H9-e9, but any thoughts from clever

engineers would be appreciated.

Pics added

Description

Description

[Edited on 17/3/20 by GRRR]

pigeondave - 19/3/20 at 12:12 PM

Can't help with the question, but have one of my own.

What's the PCD of the hubs (wheel end) ?

I thought it was only Saab hubs which have a ford PCD?

nick205 - 19/3/20 at 01:39 PM

Don't Peugeot hubs have the same PCD as Ford (different centre bore diameter though)?

pigeondave - 19/3/20 at 01:59 PM

quote:

Originally posted by nick205

Don't Peugeot hubs have the same PCD as Ford (different centre bore diameter though)?

Yes, but i don't think they do a bolt on hub/bearing like the one shown in the pic.

I believe that AB Performance uses the Saab ones machined down, unless its a special made one.

I've only ever seen pics as Stoneleigh falls wrong for me most years

coyoteboy - 21/3/20 at 12:48 PM

Think a clearance fit is too loose for this use, H9e9 is not a normal combo. You want a transition fit so it's snug and yet doesn't require

mechanical fitting. H7h6 ish. That interface carries all your vertical loading to prevent your bolts getting bending loads, any gap will mean the

clamping friction is all that is preventing your bolts seeing bend.

You might get away with it, but id prefer tighter if it were me.

Fwiw I am using audi bolt on units liike above but with the correct pcd.

[Edited on 21/3/20 by coyoteboy]

GRRR - 22/3/20 at 10:10 PM

Awesome thanks for the reply Coyoteboy

phelpsa - 24/3/20 at 09:56 PM

On a road car these sorts of interfaces will be a decent clearance as it makes assembly much quicker/easier. The ones I have worked with in the past

have been something in the region of 25-50 micron diametral clearance. The reality is that the spigot is only really there for location, the clamping

face transfers the load in all but the heaviest of impacts. Obviously a transition fit would be better but probably not necessary.