Home Brew ITBs - The story so far

RazMan - 25/10/10 at 02:33 PM

As some of you know I am converting the ST200 (Duratec V6) lower inlet manifold into throttle bodies. It just made sense to me - why not use the

original casting rather than spend £1500 for a set of Jenveys TBs? The process was much easier than I thought but still took some time to design and

machine.

Basically I had to remake the spindles and make new oval butterflies to add to the original six, making twelve in total.

New butterflies

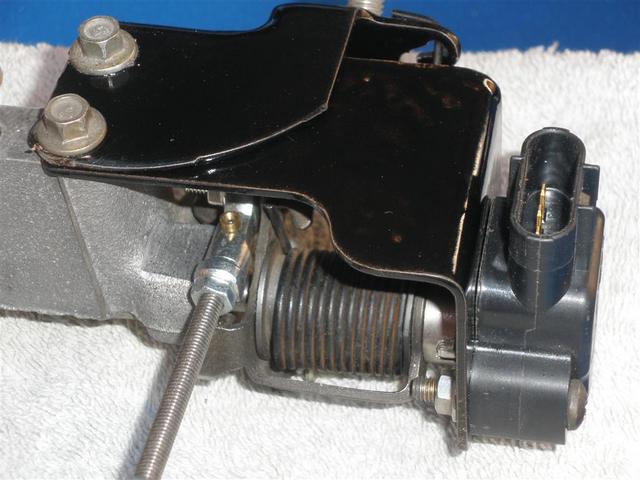

Then the TPS needed to be attached so a bracket was fabricated, mounting it on the end of one of the spindles.

New TPS

I am not certain that the butterflies are sealing well enough, although they seem to be about as good as the original ones. I am a bit concerned that

they will let too much air past at tickover so we will have to see what happens on a test run later - just waiting for the injectors to come back from

being cleaned and tested.

Next we come to the upper section which will involve some fairly creative 'siamesed' trumpets, so I am looking at getting them machined -

more to come later as things progress .....

[Edited on 25-10-10 by RazMan]

matt_gsxr - 25/10/10 at 02:58 PM

That looks good.

I hope that they seal well enough to get a decent idle. If not you can always retard the ignition at low TPS.

How are you going to balance the individual banks of 3? You could tap the butterflies for jets. But how could you measure the MAP for each

cylinder.

You might also want to swap the rose joints for a left and right handed thread to allow the TBI's of each bank to be adjusted (by more than a

single thread).

Excellent work, I am sure you have some elegant solutions.

Matt

[Edited on 25/10/10 by matt_gsxr]

RichardK - 25/10/10 at 03:08 PM

Nice work there mate, looking really good, looking forward to the start up vid

Cheers

Rich

RazMan - 25/10/10 at 03:11 PM

Hi Matt, If they don't seal well enough I will probably try again- machining ovals can be a bit tricky. Good call about retarding the ignition -

I didn't think about that

I have inserted air bleeds in the casting - you can see them in the inside of the casting. I am not sure if I can use them for balancing but at least

they are there for vacuum if nothing else.

The link between the banks is simply made with a couple of M5 rod ends and studding which I had laying around, so this will be replaced with a couple

of M4 ones with L&R threads for ease of syncing the banks.

boggle - 25/10/10 at 03:16 PM

can you knife edge the butterflys? i found this helped on my subaru for sealing on shut...

RazMan - 25/10/10 at 03:54 PM

This is a new area for me so I am not really sure how well they need to seal. They are quite an involved, oval shape and if not done right, they will

'bind' in the bores or seal badly. At the moment I can see a fair bit of daylight through the bores and knife edging wont make much

difference so maybe I need to take a closer look.

The original butterfly is on right - my new one on the left - they are in the closed position believe it or not

TB leak

[Edited on 25-10-10 by RazMan]

jollygreengiant - 25/10/10 at 04:35 PM

It may seem a bit simplistic, but surely could you not have just ordered a second set of butterfly's?

RazMan - 25/10/10 at 04:39 PM

If only it was that easy  The new butterflies are 33mm and a little smaller than the stock ones, so my only option was to fab them, along with the

new spindles which were turned from stainless rod - a jig was also made to support the fragile spindles while they were milled.

The new butterflies are 33mm and a little smaller than the stock ones, so my only option was to fab them, along with the

new spindles which were turned from stainless rod - a jig was also made to support the fragile spindles while they were milled.

matt_claydon - 25/10/10 at 05:52 PM

Interesting project. Could you explain how the OE setup works though? Why are there throttles in the manifold and what are the 'open' tubes

for?

MikeRJ - 25/10/10 at 07:16 PM

quote:

Originally posted by RazMan

If only it was that easy  The new butterflies are 33mm and a little smaller than the stock ones, so my only option was to fab them, along with the

new spindles

The new butterflies are 33mm and a little smaller than the stock ones, so my only option was to fab them, along with the

new spindles

I think I would have been tempted to bore out the throttle casting a little and use existing butterflies! As you say, it's very involved and

very precision work to create the right shape to the tolerances needed.

Project7 - 25/10/10 at 08:13 PM

quote:

Originally posted by matt_claydon

Interesting project. Could you explain how the OE setup works though? Why are there throttles in the manifold and what are the 'open' tubes

for?

I believe there is a conventional single throttle body 'upstream' of the ports shown here. At a certain RPM/throttle angle the original 6

butterflies open, controlled by the ECU, to allow greater air flow in to the engine. This has the effect of increasing air velocity at lower rpm and

maximising torque.

Seems like a good project, but i think you might be right and at present those butterflies will flow too much at idle.

matt_gsxr - 25/10/10 at 08:41 PM

Only one way to find out!

I too am looking forward to the start-up.

My gut feeling from the bike ITB's that the gap is on the large side, but I am a pessimist.

The gap on the original butterfly isn't a useful reference as normally all the flow would go left, so it doesn't need to seal, so it

isn't like a normal butterfly which actually controls the idle.

Nice work on the bleeds, on 4 cylinder bikes where their is limited inertia there is massive sensitivity to throttle balance, so it would be good to

have a way of managing that.

Matt

RazMan - 25/10/10 at 09:24 PM

quote:

Originally posted by Project7

quote:

Originally posted by matt_claydon

Interesting project. Could you explain how the OE setup works though? Why are there throttles in the manifold and what are the 'open' tubes

for?

I believe there is a conventional single throttle body 'upstream' of the ports shown here. At a certain RPM/throttle angle the original 6

butterflies open, controlled by the ECU, to allow greater air flow in to the engine. This has the effect of increasing air velocity at lower rpm and

maximising torque.

Seems like a good project, but i think you might be right and at present those butterflies will flow too much at idle.

That's absolutely right. The dual length runners are controlled by an actuator which opens the secondary butterflies at around 4000rpm so the

engine gets all the air it can when under wide throttle openings but still retains maximum gas speed (and torque) in the lower rev range. I had

already removed the secondaries as they were a pain to map, plus the extra torque was only needed for a car weighing three times as much as mine

quote:

Originally posted by matt_gsxr

The gap on the original butterfly isn't a useful reference as normally all the flow would go left, so it doesn't need to seal, so it

isn't like a normal butterfly which actually controls the idle.

Damnit I think you just confirmed what I was thinking all along - I think I will have to remake all 12 butterflies and see if I can get a better seal

[Edited on 25-10-10 by RazMan]

paulf - 25/10/10 at 09:35 PM

How have you machined them? I would bore out all the runners to a standard size and then make a jig by machining a bit of bar the same diameter to an

angle to match that of the closed butterfly's.You could then rough machine the disks before gluing them to it and machining to finished diameter

which would leave them oval to match the bores.

Paul

RazMan - 25/10/10 at 09:57 PM

The butterflies were done basically as you describe - tbh its one of the more fiddly jobs I entrusted to an engineer with better skills - I am fairly

ok on the simple stuff and he offered to have a go. I reckon with a bit of tweaking of the draft angle we will get there.

Boring out the smaller bores would mess up gas flow as the ports in the heads are matched to the smaller bores.

RazMan - 25/10/10 at 10:27 PM

I've just been googling for info on butterflies and it seems that a lot of the racing boys apply a small amount of sealant (not sure which type)

around the bore surface where the butterfly almost touches, therefore making a better seal. Interesting - has anyone else discovered this tip?

interestedparty - 26/10/10 at 05:30 AM

The sealant, if you choose to use it, will need to be really good stuff if it doesn't end up being sucked into the engine having worked loose in

what must be quite a hostile environment.

But how good a seal will you need, though? What is going to let the idle air through?

RazMan - 26/10/10 at 06:56 AM

I think that some kind of silicone was mentioned - I will have another look later today and report back.

Looking at the old (single) 70mm TB, the butterfly seems to almost completely seal the bore. I didn't have an idle control valve but plan to on

this setup (hence the vacuum takeoffs) so I think I need to aim for as good a seal as possible on all 12 bores if I am to allow the ICV to do

it's job and get a stable idle.

*edit* Found a product called Throttle Coat which help achieve a better

seal on the spindles.

...and here's a thread

discussing a similar problem and Molykote 321 seems to be the stuff. It's a dry film lubricant and a few manufacturers apply it to butterflies as

standard - many people are 'cleaning' their TBs and messing up the idle as a result

[Edited on 26-10-10 by RazMan]

MikeRJ - 26/10/10 at 01:39 PM

quote:

Originally posted by RazMan

Boring out the smaller bores would mess up gas flow as the ports in the heads are matched to the smaller bores.

If it's only a small difference it won't hurt, or you could just blend the ports to the runners and get a better than factory match.

RazMan - 26/10/10 at 03:26 PM

I've come this far so I don't want to change anything at this late stage.

I think I've found the problem - a combination of things really

- I made the butterflies from 1.2mm steel and they should be 1.0mm (schoolboy error - duh!)

- The angle of the chamfered edge is all wrong, causing it to bind in the bore.

Hopefully it will be sorted in a day or two

coyoteboy - 5/11/10 at 04:16 AM

Interested to see how this works and not wishing to be a pessimist but the reason it's a 1500 part is the work that goes into getting it right.

From experience on a bike engine (v6 is larger cc so gap size less critical so you may have some leeway) those sorts of gaps will see you at 3-4000

rpm with no load. It really is ultra tiny tolerances - I had a pinhole in an injector seal throwing one cyl into misfires on a previously perfectly

tuned engine. I've had a perforated weld in a plenum cause a 500rpm rise in idle. We had a single throttle plate made up for a 600cc plenum with

tighter tolerances than that and couldn't get the idle below 3000 without using the old palm-throttle.

Good luck though, I'm hoping you have better results than I, it being a larger engine.

Ivan - 5/11/10 at 07:49 AM

I was reading this with interest - just wandered :

If your object is to get rid of the secondary opening interfering with your tuning efforts and you weren't too worried about low down torque, why

not remove the secondary butterflies completely with their spindles and retain the single throttle body or fit a larger one - that would give a large

increase in air flow at high revs as throttle plates and spindles have a significant impact on air flow.

You would also save weight and complexity and a lot of frustration and time getting this whole set-up working.

I think you will actually lose power with your proposed 12 throttle plates and spindles because their combined area when fully open must equal at

lease one of the runners and the turbulence they create will also reduce flow.

I think the above will work well for you and fits in beautifully with the KISS principal - also easy to test and restore if it doesn't work.

Another thought - if low down torque really didn't matter to me and the head runners suited I would machine out the web between the manifold

runners and make one large oval port per cylinder.

[Edited on 5/11/10 by Ivan]

RazMan - 5/11/10 at 09:10 AM

When I built this engine I had already removed the secondary butterflies to improve airflow, then re-mapped it to make the most of the extra

breathing. The results were not too bad (over 200bhp) but I have read reports that ITBs can give another 30 ish bhp so this project was dreamed up as

a way to ditch the (now redundant) dual-length runners and install ITBs without the expense of going to the likes of Jenvey and get my wallet

lightened by £2K in the process. It all seemed so simple in the dreaming stage and making the spindles was a very straightforward procedure once a jig

was made.

The new butterflies however are a bit more of a challenge but once we figured out that the bores are very slightly tapered (only by 0.5mm) it all fell

into place again. We now need to hone out the bores and remake the butterflies again (hopefully next week)

I agree that the tolerances need to be pretty close and that is why we have decided to remake the new butterflies. They should be at least as good as

the originals by the time they are finished. I am hoping that the relatively small air gaps will allow a stable tickover but I guess we will just have

to wait and see how the engine runs. If neccessary I may have to apply a small amount of Molybdenum dry film lubricant around the sealing faces but I

am hoping it doesn't come to that, although it appears that many manufacturers like Honda and Suburu do this as standard practice.

The old inlet manifold is a very heavy and complex labrynth of twists and turns and if I understand the principles of using throttle bodies correctly,

it is more about the air's change of direction that saps power - ITBs offer the straightest route to the cylinder and the spindles are a

relatively small obstruction as a trade-off.

It's a theory anyway

[Edited on 5-11-10 by RazMan]

coyoteboy - 5/11/10 at 02:46 PM

FYI - there's the idle-stop throttle plate gaps on a monster american V8, with the one carb feeding all 8 cyls IIRC, so you're gonna want to

get them nice and precise - they'll have to fit much better than the originals that came with the fanimold.

[Edited on 5/11/10 by coyoteboy]

[Edited on 5/11/10 by coyoteboy]

RazMan - 5/11/10 at 03:04 PM

I reckon mine should be a lot closer than that, although I agree that with a smaller engine (only 2.5L) they will have to be better than my earlier

effort. The original butterflies actually fit quite well and once the slight taper is removed from the bores, I stand a better chance of achieving a

good seal. As a last resort I will find some suitable sealant like the Moly dry film lubricant to close the gaps a little more.

paulf - 6/11/10 at 10:12 AM

I dont think the dry film type products will do the job you require and was under the impression that manufacturers used it as a means of stopping

dirt from building up on the butterfly.My gsxr butterflys barely show a gap when held up to the light and if you are intending to use an idle valve

then they need to be fully closed.I would try and make them slightly oversize and hand fit them if necessary using engineers blue and a scraper.

Paul

quote:

Originally posted by RazMan

I reckon mine should be a lot closer than that, although I agree that with a smaller engine (only 2.5L) they will have to be better than my earlier

effort. The original butterflies actually fit quite well and once the slight taper is removed from the bores, I stand a better chance of achieving a

good seal. As a last resort I will find some suitable sealant like the Moly dry film lubricant to close the gaps a little more.

Badger_McLetcher - 6/11/10 at 01:26 PM

This is a very interesting project, in the proper spirit of locosting

Though the parts require fine precision, it seems this should be within your means.

RazMan - 7/11/10 at 12:44 PM

After some discussion in another thread I have decided that an Idle Control Valve will just complicate things and I will hopefully control the

tickover with some timing control with the ecu - cold starting might be a challenge but again the ecu has adjustments which can compensate here too.

I have vacuum feeds from each of the primary bores so at least I can use these to control the fuel regulator after joining them in a mini plenum.

[Edited on 7-11-10 by RazMan]

RazMan - 10/11/10 at 05:26 PM

I've been busy this week! My new best friend in Taiwan has been very helpful and made a prototype of my trumpet design.

Due to machining size limitations (and to keep cost down) we decided to make a 'layered' construction from billets that were already in

stock. Quite unique I think you will agree

Here are the four layers ..... 6mm Baseplate, 2 x 32mm funnel sections and a 9mm flared bell

Components

...... which stack together making the complete multi-layer trumpets. The whole assembly is held together with four vertical bolts and a lick of

gasket compound. Internally it looks very smooth as far as gasflow is concerned - the 'stepping' is purely external and was done for faster

machining time

Sand blasted

VOILA! 80mm trumpets done the Locost way

The new butterflies have now been re-made and they fit much better than the previous attempt - I'm off to the platers tomorrow to get them ready

for assembly next week.

[Edited on 10-11-10 by RazMan]

MikeR - 10/11/10 at 06:35 PM

wow - how much did that cost?

MikeRJ - 10/11/10 at 11:10 PM

Very neat, some hours have been put into that! One thing I meant to ask - how will you balance airflow through the individual throttles?

RazMan - 10/11/10 at 11:29 PM

I can't comment on the pricing .... yet, but lets just say if I was to get it machined in the UK it was going to cost SIX TIMES as much

Honestly, while I can appreciate that UK machine shops have overheads it really doesn't make any sense that I can go to Taiwan and get such great

prices AND they did the CNC design from a very basic DXF file that I knocked up - a real no brainer.

Honestly, while I can appreciate that UK machine shops have overheads it really doesn't make any sense that I can go to Taiwan and get such great

prices AND they did the CNC design from a very basic DXF file that I knocked up - a real no brainer.

As far as syncing the airflow goes I am banking on the fact that they are all exactly machined and mounted on common shafts which *should* mean that

they will be fairly close. Having said that, I have the option to install needle valves in each bore if things are too rough.

coyoteboy - 12/11/10 at 02:30 PM

Who's your friend in Taiwan? I'm sure plenty of people could send him more work.

RazMan - 20/11/10 at 01:30 PM

I actually meant Thailand  and he is a supplier of all sorts of go faster goodies for mostly motorbikes.

and he is a supplier of all sorts of go faster goodies for mostly motorbikes.

A little bit more progress this week - I have now remade the butterflies and the seal is much better, but after doing some research I decided to make

it even better by applying a little Molykote dry film lubricant to the mating surfaces. Apparently manufacturers such as Honda, Suburu and even Jaguar

use this compound for the same reasons and this often gets removed unintentionally during cleaning or modifying the TB, with a bad idle as a result.

Basically it is 'floated' into the tiny gap between the butterfly and throttle body, capilliary action holding the compound in place while

it cures. The result is a PERFECT seal which means I might be able to use an idle control valve if I choose now.

Here's a shot of the seal

Description

[Edited on 20-11-10 by RazMan]

bimbleuk - 20/11/10 at 03:40 PM

Doesn't surprise me about the cheaper manufacturing in Thai/Malay. I bought a tapered plenum with internal trumpets from a seller on Ebay. Bit of

a leap of faith at the time but the cost was at least half of an equivalent plenum fabricated over here plus it was cast which makes for a much

stronger design. Arrived in 4 days from the order which I was impressed by and served me well for a few years. Unfortunately he cottoned on about

pricing and the plenums have gone up considerably since.

matt_gsxr - 20/11/10 at 10:48 PM

Looking good. When are you going to be in a position to start the engine up with these installed?

Exciting times. Are you planning on going to "Product" with the layer cake approach, or is the long term plan a solid lump? Personally I

think a solid lump would extract more money from my pocket than the sandwich. Just interested.

Matt

RazMan - 20/11/10 at 11:11 PM

I am hoping to get a revised version of the trumpets next week. The profile of the flared end has been changed to make them look more conventional and

also improve the airflow a little more. Once I have got the prototype in my hot little hands I will bung it on my engine and start mapping it straight

away. I guess a trip to the rollers is the only thing that will prove its effectiveness but I will certainly use my 'butt dyno' while

mapping on the road.

The 'layer cake' idea was originally thought up as a way to prototype the design but if it works well I might even call it a feature.  It

will certainly reduce the cost of the kit (which I hope to be able to offer at a very competitive price btw

It

will certainly reduce the cost of the kit (which I hope to be able to offer at a very competitive price btw  ) and if airflow isn't compromised

I see no reason to make the kit more expensive. I am hoping that it will fit under the bonnet of a standard Mondeo / Cougar without any mods to the

bonnet, which might please some of the Ford V6 boys out there who are looking for a few extra horses. If all goes to plan I will offer the kit on an

exchange basis, taking a standard LIM and supplying a new, reworked version + fitting kit back to the customer.

) and if airflow isn't compromised

I see no reason to make the kit more expensive. I am hoping that it will fit under the bonnet of a standard Mondeo / Cougar without any mods to the

bonnet, which might please some of the Ford V6 boys out there who are looking for a few extra horses. If all goes to plan I will offer the kit on an

exchange basis, taking a standard LIM and supplying a new, reworked version + fitting kit back to the customer.

RazMan - 1/12/10 at 11:55 PM

Update time:

At the third attempt I have finally got the butterflies to fit nicely and with a tiny adjustment to the timing it is rock steady at 850rpm with an AFR

of 13.5 so I am a happy chappy. Apparently a lot of 'proper' ITBs have idle issues so I am quite happy with the results, considering

I've got twelve of the little blighters - and the sound of a V6 on ITBs is really nice  I have yet to receive the trumpets which should be here

any day now, so it looks like my cunning plan is finally starting to work now!

I have yet to receive the trumpets which should be here

any day now, so it looks like my cunning plan is finally starting to work now!

I will post some pics when I get the trumpets ....

RazMan - 6/12/10 at 05:35 PM

The prototypes have arrived - yay! I was pleasantly surprised to find that they fit the LIM perfectly and only the finish is not quite as

'finished' as I would like - not bad for a first attempt though.

Trumpet Prototype

Here is a closeup showing more detail - the finished version will be polished and anodised in a choice of colours.

Trumpet Prototype

They certainly look the part and I can't wait to take her out on the road to see how they perform. Judging from the AFR gauge (wideband) the

engine is running quite a lot weaker due to the extra airflow so I have tweaked the map to get things ticking over nicely at 850rpm (didn't

expect it to be that good!) and further mapping will be done when I can take her out for a spin. The sound of a revving V6 is quite intoxicating and

the trumpets have really made everything more responsive and 'angry' sounding grrrrrr

Xtreme Kermit - 6/12/10 at 05:51 PM

Looking good!

RazMan - 26/3/11 at 03:30 PM

Just a little update as I have been very busy lately and haven't had time to work on the car.

I got a couple of foam air filters from Ram Air and after some modding they fitted a treat. First I had to make some baseplates with all of the holes

in all the right places - measure twice, cut once etc

Base Plates

The tops of the trumpets are sandwiched into the 'layer cake' design and I'm really chuffed with the result. Then the filters

themselves go on top.

Foam Filters

After some initial 'challenges' with the butterflies letting too much air past, I managed to get the engine running quite well and ready for

some mapping on the road. The tickover is still a bit high (1200rpm) but I can live with that for the time being.

The first thing I noticed when opening the throttle on the road was the increase in induction roar - what a glorious noise! It has now got a kind of

shrill harmonic more akin to a bike engine. I put this down to the fact it is now breathing through 12 small trumpets so the smaller apertures play

higher 'notes'. Combined with the deeper, slightly unbalanced burble of the exhaust note it really sounds gorgeous and the whole project was

worth it just for that noise

The mapping took me 3 tank fulls of 97RON to get close to how I want it, but I am sure a 'proper' mapping session will get it even better.

However it is fine for me right now and I continue to tweak the map every time I go out in the car (quite often now the weather is getting better)

Performance wise I am quite impressed with the power delivery. It seems to be much more responsive, especially in the lower half of the revs, and

really gets a move on at the top end too - with a really lovely howl which is quite addictive  Can't wait to see what power it is producing but

my 'butt dyno' says it is quite a lot more than stock now.

Can't wait to see what power it is producing but

my 'butt dyno' says it is quite a lot more than stock now.

More to follow later

[Edited on 26-3-11 by RazMan]

Yazza54 - 26/3/11 at 03:52 PM

Trumpet porn

Xtreme Kermit - 26/3/11 at 07:17 PM

rusty nuts - 26/3/11 at 07:48 PM

Nice.

rusty nuts - 26/3/11 at 07:48 PM

Nice.

Yazza54 - 26/3/11 at 08:09 PM

Whats the car?

RazMan - 26/3/11 at 09:56 PM

quote:

Originally posted by Yazza54

Whats the car?

.jpg)

It's still my Aeon GT2 - 5 years on the road now but I just can't stop fiddlin' wiv it

[Edited on 26-3-11 by RazMan]

The new butterflies are 33mm and a little smaller than the stock ones, so my only option was to fab them, along with the

new spindles which were turned from stainless rod - a jig was also made to support the fragile spindles while they were milled.

The new butterflies are 33mm and a little smaller than the stock ones, so my only option was to fab them, along with the

new spindles which were turned from stainless rod - a jig was also made to support the fragile spindles while they were milled.