I'm having trouble imagining how this will work

Hey all.

My latest engine build is going to be a twin charged effort.

For shits n giggles really...

In the effort of mechanical simplicity im looking for a one way butterfly valve.

Im not after a bypass valve actuated by a solenoid nor ref from vac/boost but a simple off centered eccentric valve that will flow air one way only

Like a throttle body with spindle shaft offset to one side..

Ive looked online all eve and found nothing.

Anyone know where to find such an item say in 2" I/D

Many thanks!

Try looking for a flap valve or duckbill valve.

I realise you have said you don't want to use a bypass but.......

Have you considered using EBC valve or even a manual one to bypass the supercharger at a chosen boost?

I guess you want a small supercharger from low down then turbo will take over and the supercharger will be bypassed using your one way valve?

Is there one of these in the VW twin charge engine that you can get from a scrappers ?

Two stroke reed valve

[Edited on 22/1/15 by mark chandler]

Is this going on the NA Cossy engine that you boosted with an Eaton supercharger a while ago?, or another project.

Ian

Forgot how to multi quote but thanks for the suggested search ideas will get on that tonight.

The charger will feed the turbo and will also keep the one way valve shut until the turbo spools more than the eaton can supply so when negative

pressure is seen by the one way valve it just simply falls open. No pressure switches, no fiddling with the db15 outs on the megasquirt to try and

control it all.

The charger will not be disengaged but still run as normal.

This is another project. The blown cossie is back home in Ireland. Im now in canada. Using a 2.3 lima

Well I did find a one way check valve. 2 1/2" available in all manner of materials with a selection of different rubber seals.

Thinking of an all aluminium body and aluminium blades with a viton rubber seal.

This should allow the turbo to draw air past the charger and not give any noticeable switch over like twin charged setups sometimes have.

Comments?

http://www.thevalveshop.com/menu/manual/techno/eht.html

Have you got a sketch of how you propose to plumb this up?

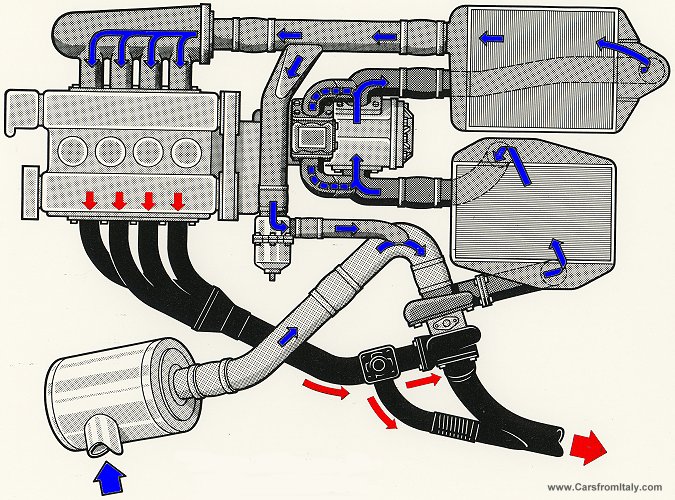

I'm having trouble imagining how this will work

Yeah im needing a diagram for this. I'm in the early stages of twin-charging too but im using the tubby to feed the blower and using the oem electronic bypass on the SC

Here's a (very) rough sketch whilst eating my breakfast.

What are the benefits of running them in series rather than the usual parallel?

If I were doing this I would have used the parallel route with an ecu (rpm/load) operated valve to select the supercharger output at low rpm and turbo

at high, the supercharger could be opersped (overspeeded?) and dropped out with another ecu switch using the Mercedes clutched pulley to get a bit

more boost low down.

Yes thay does sound good. Thought about that but my idea is for simplicity. No switches between the two systems, no noticeable switch over as the one

way valve simply opens when the charger becomes a restriction.

My m62 doesn't have a mag clutch.

As others have said try the two stroke reed valve, Suzuki RG500, Yamaha TZ etc...

You say you want 'Like a throttle body with spindle shaft offset to one side' you can't do this, if you move the spindle off centre the

disc cannot open, as its widest part will try to sweep into a narrower part of the tube, unless you step up the diameter of the tube at the fulcrum

point.

Two stroke reed valve is gonna produce large efficiency drops IMO. Better to do it the way all the OEMs do it and use either a vacuum switched or

electronically controlled option.

What sizings are you using for the super/turbo combination? I did it turbo blowing into super because that way my peak power is primarily limited by

the size of the turbo (not wanting to swing a big super off a relatively small engine).

I have an m62 from a cobalt and a t4 turbo.

Im concerned with having the blower after the turbo as it will really heat the poo out of the boost and were really into compound charging then. The

way im trying to go about it gets the charger out of the system (well sort of) in the upper rev range. A boost gauge between charger and turbo and

another gauge after turbo would show when the charger goes out of use and running turbo only. It should seamlessly glide from compound to the turbo

being primary?

I like the idea, no reason not to think outside of the normal box. I don't see a 2 stroke reed valve working at all well in this application, but

i don't see any reason the valves you linked to won't work.

Ian

This is parallel charging not compound (as the turbo is bypassing the SC) Ugg. The issue I see is that the reed valve will pose a restriction, it will

take some positive flow (and boost/restriction) to hold it open. If you just use a vac actuator that compares the SC output to the turbo output (pre

valve) it can be made to open entirely mechanically when the tubby is producing more boost than the SC can. The issue you woud have with any of them

is when the reed/vac valve opens,the boost from the turbo will drop momentarily (less restriction) and the valve shut. You're going to get

oscillation/chatter which may affect drivability around that point. Assuming you size the tubby MUCH higher than the SC and boost hard right through

it you probably wont notice.

The benefits of compound charging are that you get massive pressure multiplication, at the expense of efficiency drop. (boost multiplies but so does

efficiency loss). PArallel systems like this give the low boost of a SC at good efficiency, then bring in the turbo at higher efficiency, meaning the

peak boost will be lower but the overall system efficiency higher.

This is the route I am taking (though that's still reliant on me being able to fit the eaton under the bonnet, which isn't looking likely

just now...)

NoRoom

[Edited on 23/1/15 by coyoteboy]

quote:

Originally posted by Craigorypeck

Here's a (very) rough sketch whilst eating my breakfast.

Not too fussed on the reed valve. I want a nice open valve that will flow nicely when open. Not even gonna have a spring on it.

I don't see a chatter or stumble issue as if say the charger is making 8psi through the turbo. The turbo spools up and creates 8psi, as it

climbs psi the one way valve opens and the turbo draws air past the charger. This fresh air mixed with an unpressurised charger supply will be nice n

cool

If this valve was controlled via boost ref or electronically I can see it stumbling or having issues as finding that sweet spot will be a challenge?

In my mind this is incredibly simple... maybe too simple.

Now coming off WOT... I havekno idea how it will perform!!!

Coming off WOT should be ok as the bypass will open and the dump valve will dump so if the butterfly valve bounces about you won't notice.

Well let's hope not