flak monkey

|

| posted on 6/12/14 at 05:58 PM |

|

|

Twin Turbo Small Block Chevy build

I've been working on this project for a while, started off with the rebuild of my '80 Camaro.

Its currently got a 355 SBC which is putting out about 425hp. Enough to have some fun with, but I always like a bit of boost. Its got a 4.11 12 bolt

with Moroso Brute Strength posi, steel shafts etc. Hood and front bumper cover are carbon/kevlar mix. 700r4 transmission with PATC Junior Raptor

upgrades.

It's also running on Megasquirt EFI with a holley MPI manifold and 1000cfm throttle body. I made provision for a lot more power when I rebuilt

the car, just needs bigger injectors and another fuel pump fitting at the back and it'll provide all the fuel it could need up to about 1000hp,

not that I am planning anywhere near that.

(I've fitted hydroboost since the underhood shot was taken too!)

So I am currently building up a short block with about 9:1CR (my current is 10.8:1) using a late 1 piece rear main, roller cam block. Got the block

and a GM forged steel crank as a start. Plan on using my current Bowtie Phase 2 heads which have had a lot of porting work done. I just need rods and

pistons to get the block built.

After some more research I've decided to go with some bigish turbos and waste gates from the outset. So after talking with SS Auto Chrome

http://www.ssautochrome.com/ I've decided to go with some GT3582R turbos.

T4 frame with T3 mounting flange

.70 A/R Compressor

.82A/R Turbine

Compressor Wheel: 61.3 /82 mm

Turbine Wheel: 62 /67.8 mm

These should be perfectly suited to the sort of power I want to be making, and have a bit of head room should I want a bit more later on.

Along with that I've got a pair of 60mm v-band waste gates and a 50mm BOV.

The 50mm BOV. I've fitted the lowest pressure spring for the time being.

Final goodies was a pair of 60mm wastegates. These have 4 springs with them for different boost levels. They start to open at 8psi and fully open at

12 psi. I also have over boost protection on my ECU, so I'll be using that as a final safety device.

The 700r4 transmission was never going to be strong enough so it's out and gone off to a new home - so made a proper start on the 4L80E. Bought

it in bits, the only thing I knew about it was there was no drive in most gears. Clean down the case and rebuilt the gear train, fitted a new rear

band, new output shaft seal and a few other bits and dropped it into the case then set about rebuilding the clutch packs and drums.

All looked good - could still see the writing on the OD and direct clutches. Not so good when it came to the forward clutch though....

No friction material left at all and the bevel/spring plate was flat!

Soon became apparent that whoever did the last rebuild didn't do a very good job... these are the seals from the apply piston

Needless to say they weren't going to be doing much at all.

Got a billet input shaft and clutch hub. There's a significant difference between the original input shaft and the billet one, no undercuts at

the splines and seals

Shouldn't break that in a hurry! Just waiting for a torque converter so I can get it back in the car - then I'll need to make a cross

member for it amongst a few other bits. It's not the prettiest, but it's whats inside that counts

Also made a start on the block. It's a '90 2 bolt main block out of a day van. Nothing special about it really. Checked the cylinder wall

thicknesses and they are all good - no core shift at all. Its been bored .040 recently so a quick hone of the bores will sort that. Obviously a 2 bolt

block isn't going to stand up to the turbo power very well.

First step in fixing that is a set of Milodon splayed main caps. Measured them up and milled the pads on the caps to suit the registers in the block.

Fitted them back on and drilled and tapped the outer bolt holes. It's now ready for line boring.

After that I acid cleaned the water jackets and then filled the block with grout up to the bottom of the water pump holes.

I've also made a start on cleaning up the engine bay and making room for those turbos. First job on the list was making a pair of tanks to

replace the washer bottle and expansion tank.

So I got some 2" stainless tube and knocked up 2 of these things

Turned up some aluminium caps for the filler necks and fitted them in the space between the core support and the radiator. They don't hold a lot

of fluid (about 1 litre each) but its more than enough for the purpose

And finally the turbos are going to sit in the front corners of the car. I've just had the flanges cut ready to make a start on fabricating the

headers. That's the job for december!

Sera

http://www.motosera.com

|

|

|

|

|

jeffw

|

| posted on 6/12/14 at 06:44 PM |

|

|

Nice mate, very nice

|

|

|

big_wasa

|

| posted on 6/12/14 at 07:02 PM |

|

|

I've passed a few times and wondered if you still have her.

|

|

|

coozer

|

| posted on 6/12/14 at 07:37 PM |

|

|

Good job on the car there and nice to see ya back with another detailed mad build.

What you been up to since the rebuild of the shell??

Steve

1972 V8 Jago

1980 Z750

|

|

|

nick205

|

| posted on 6/12/14 at 09:39 PM |

|

|

A pleasure to see as always.

Did you finish the bike you were building?

|

|

|

flak monkey

|

| posted on 6/12/14 at 09:51 PM |

|

|

Thanks guys. Happy to be back to be honest!

I've been pretty busy this year in between quite a lot of custom shows, we built another bike to take to Bonneville. We got there only for the

event to be cancelled due to heavy rain causing flooding. So it's been a very expensive year in that respect.

http://www.saltflashracing.co.uk/

It was in Back Street Heros a couple of months ago too.

Sera

http://www.motosera.com

|

|

|

flak monkey

|

| posted on 6/12/14 at 09:51 PM |

|

|

Thanks guys. Happy to be back to be honest!

I've been pretty busy this year in between quite a lot of custom shows, we built another bike to take to Bonneville. We got there only for the

event to be cancelled due to heavy rain causing flooding. So it's been a very expensive year in that respect.

http://www.saltflashracing.co.uk/

It was in Back Street Heros a couple of months ago too.

Sera

http://www.motosera.com

|

|

|

MikeRJ

|

| posted on 7/12/14 at 01:37 PM |

|

|

quote:

Originally posted by flak monkey

Thanks guys. Happy to be back to be honest!

I've been pretty busy this year in between quite a lot of custom shows, we built another bike to take to Bonneville. We got there only for the

event to be cancelled due to heavy rain causing flooding. So it's been a very expensive year in that respect.

http://www.saltflashracing.co.uk/

It was in Back Street Heros a couple of months ago too.

That has a very odd engine note, sounds more like a two stroke than a four stroke!

|

|

|

flak monkey

|

| posted on 14/12/14 at 04:11 PM |

|

|

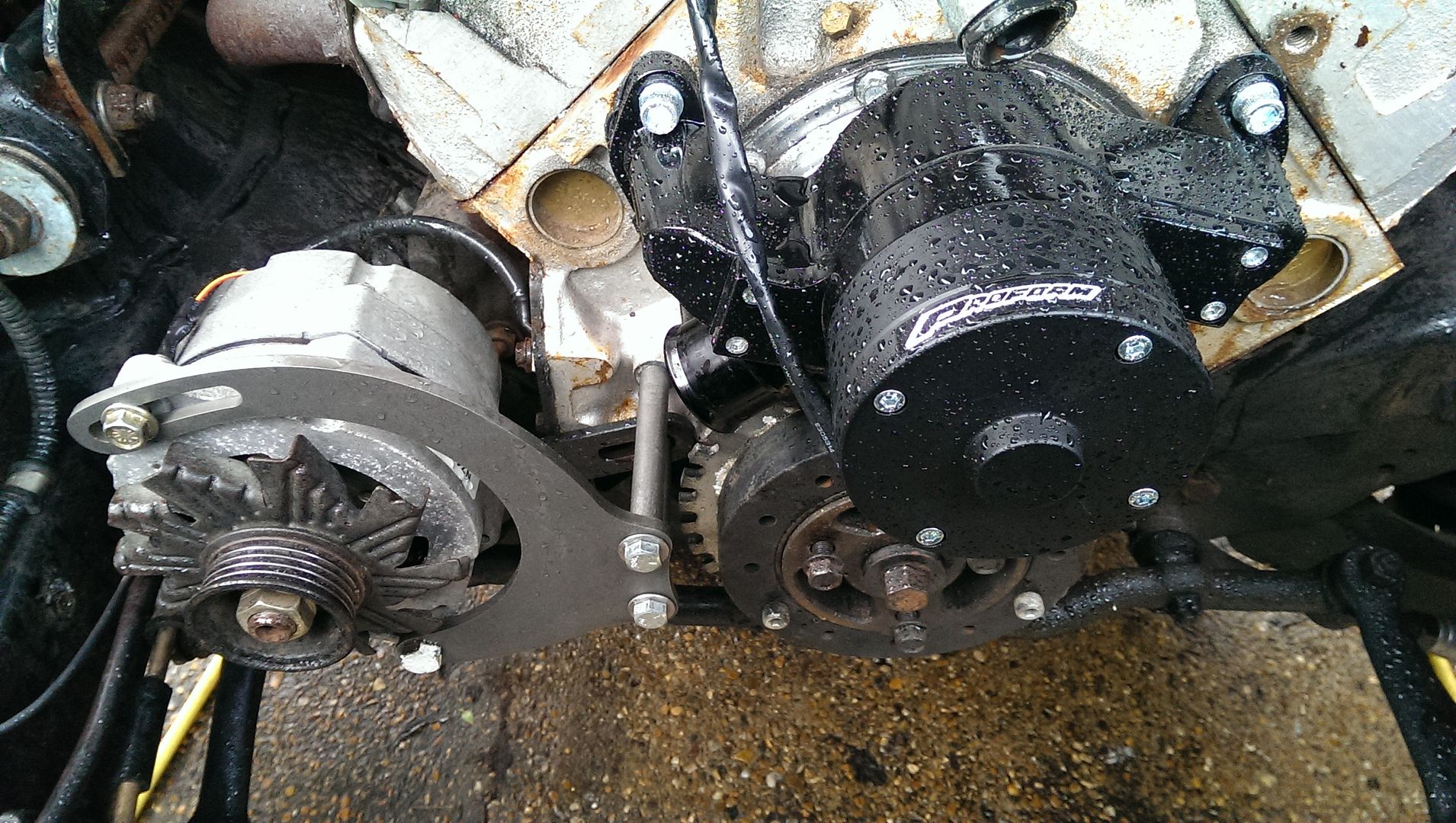

Kind of messing around with various parts on the car - ultimately all modifications for when the turbos are fitted. While the original engine is still

fitted it makes an ideal mock up and test bed for brackets etc.

I needed to clear some more space at the top of the engine bay to allow for routing of lots of hoses etc so I decided to go with an electric water

pump then move the alternator low down on the block. I've also got a power steering pump off a 5th gen camaro (type with the remote reservoir)

to make some brackets for.

I'm going to use the current fuel pump feed to power the water pump as I'll be replacing the pump feed to cope with 2 pumps later on

anyway.

Today I've got the alternator mounted up in a place I am happy with. I'm making a double poly vee crank pulley with a trigger wheel as

well (alternator and PS pump will run off seperate belts), I just need a lump of 7" diameter aluminium...

Need to also hook up the bottom rad hose, which will route between the alternator and the bracket neatly out of the way.

Sera

http://www.motosera.com

|

|

|

flak monkey

|

| posted on 17/12/14 at 08:34 PM |

|

|

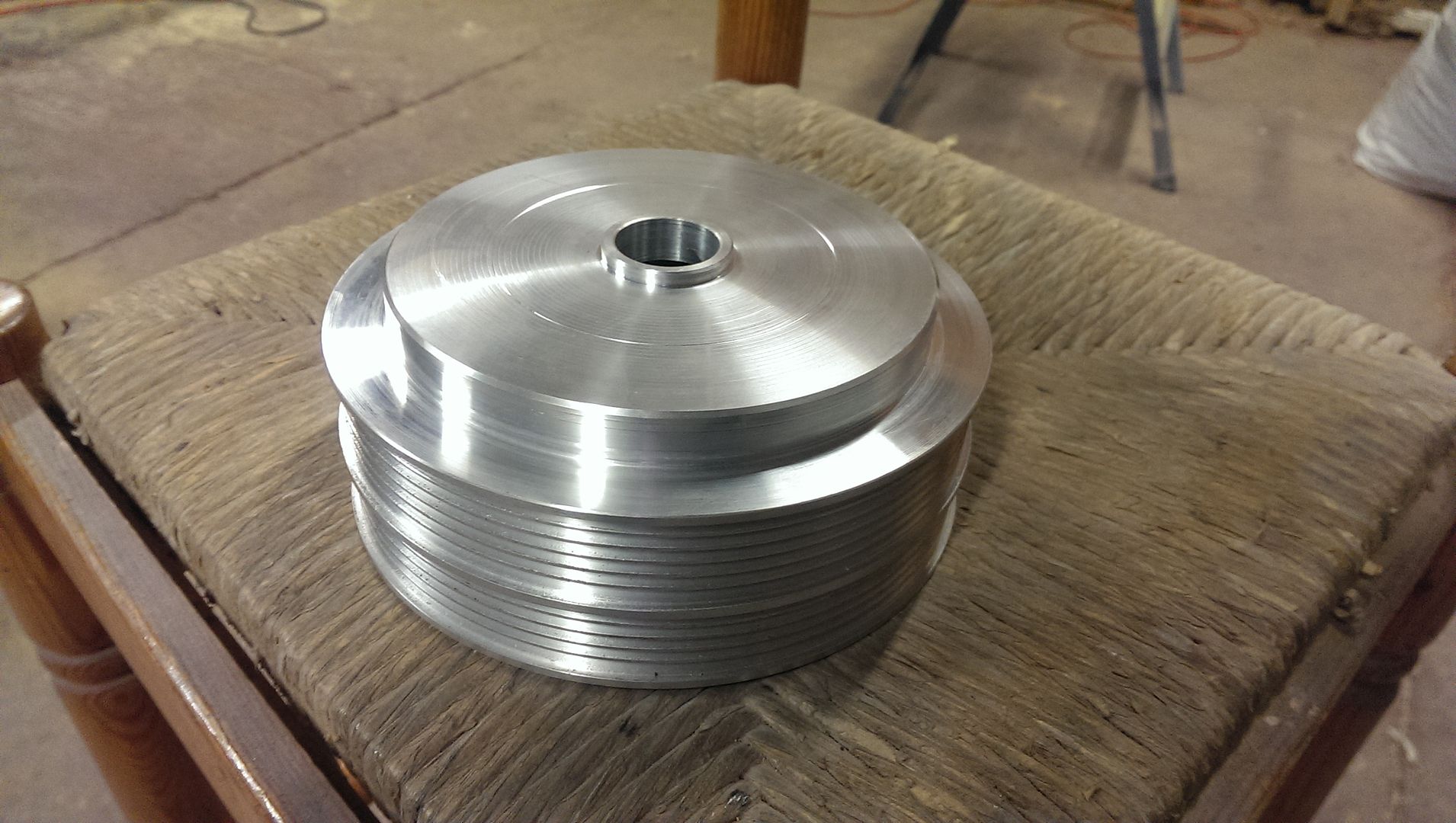

And this is what billet pulleys start life looking like.... this is destined to be the new crank pulley with trigger wheel. It will take about 6 hours

to machine it up.

Sera

http://www.motosera.com

|

|

|

BaileyPerformance

|

| posted on 17/12/14 at 09:48 PM |

|

|

Nice project :-)

One comment - your turbos, wastegate and blowoff look Chinese. If thay are cheap eBay jobbies then the wastgate and blowoff mite be usable but

I'd bin the turbos.

Mite be better to get a couple if used turbos from a large Diesel engine, I'd probably stick with internal wastegates to simplify the install,

no real advantage to external wastegates unless your running lots of boost.

|

NOTE:This user is registered as a LocostBuilders trader and may offer commercial services to other users

|

flak monkey

|

| posted on 17/12/14 at 10:26 PM |

|

|

Diesel turbos are crap in these installations. Unless you want to run a big single from a truck.

There's lots of people successfully running the same turbos in the USA with no problems at all. The Chinese ones have come on a long way in the

last 5 years so don't discount them. Many people reporting 50k+ mile life from them in daily drivers with them still running strong.

Internal waste gates are rarely big enough to prevent boost creep on big displacement, high rpm engines. Smaller T3/4 hybrids suffer massive issues

trying to keep boost under control. The GT35 and bigger turbos rarely come fitted with internal ones either. Read any write up of professional

installations of turbos on small blocks and they all say the same, dont consider internal wastegates.

The wastegates are identical to Tials, probably the same factory in China... I stripped them and couldn't find any difference....

Yes the Chinese stuff had a bad rep 10 yrs ago, but they learn quickly and a lot of those earlier problems are fixed now.

Sera

http://www.motosera.com

|

|

|

Ivan

|

| posted on 18/12/14 at 06:09 AM |

|

|

That's another exciting project from you David - close to my heart as it's something I want to do some time so will be watching this with

interest.

Have sent you a U2U as well.

|

|

|

BaileyPerformance

|

| posted on 18/12/14 at 09:27 AM |

|

|

We've seen loads of Chinese turbos over the last 5 years, as you say they are not as bad as they used to be, but still 3/4 are disappointing

regarding spool-up or smoke.

The last one was a garrett T3 (Cosworth style) copy we fitted to a 2.0 zetec, it made good power (296bhp) but was very laggy (0.48 hot side). Normally

a genuine garrett T3 with a 0.48 housing will be on full boost at 3000rpm on a 2.0, the Chinese copy was over 4000rpm.

It lasted the day on the dyno, but started to smoke from shorty after.

We fitted a GT35 copy to a Lexus v8 in an Autograss car, same story, laggy and short lived.

We mapped a golf VR6 with a GT30 copy, that one seized up (oil supply and return fine)

There is a nice range of garrett turbos fitted to new holland medium sized tractors, T3 bolt pattern, around the same size as a GT30. I'll try

and find out the details, they do appear on eBay from time to time.

A GT30, 0.63 exhaust housing is good for 500bhp,

so a pair of these would be more suitable than GT35. A large exhaust A/R really effects lag, I suggest your GT35 0.82 will be too big.

|

NOTE:This user is registered as a LocostBuilders trader and may offer commercial services to other users

|

flak monkey

|

| posted on 18/12/14 at 10:35 AM |

|

|

Thanks - if you've got any info that'd be good.

I went based on the sizes guys were having good success with in the USA both street and strip use for my engine spec. Many people have said that the

smaller turbine housings get restrictive at the power goals I'm looking for.

The car will see a fair amount of 1/4 mile action - with power goals of 850-900 hp. The GT35's I have are rated up to 600hp each.

Sera

http://www.motosera.com

|

|

|

BaileyPerformance

|

| posted on 18/12/14 at 11:52 AM |

|

|

I'm sure it will make good power, we have done a couple of Rover V8 turbos in TVRs, baby engines compared to yours, 400BHP an over 500lb/ft at

10PSI (4.6L)

I would expect 900lb/ft out of your motor, maybe not massive BHP unless you change the cam but more than enough! i'd offer to help you map it

but it would probably break my dyno!!

I'm putting megasquirt on a SBC at the moment, in a New York Taxi, retaining the duel point injection unit and converting to coil packs.

Just fitted the 36-1

|

NOTE:This user is registered as a LocostBuilders trader and may offer commercial services to other users

|

flak monkey

|

| posted on 18/12/14 at 12:40 PM |

|

|

I'm not sure what cam I am going to be using yet - probably a custom grind

Sera

http://www.motosera.com

|

|

|

BaileyPerformance

|

| posted on 18/12/14 at 01:51 PM |

|

|

quote:

Originally posted by flak monkey

I'm not sure what cam I am going to be using yet - probably a custom grind

If your going for big BHP, and sticking with large turbos with big housings then i'd just use a decent NA cam, you will loose some boost on

overlap at lower RPM but not much, the turbo / SC cams are often too mild for top end power

The last 2 turbo Rover V8s we did use used a Piper 285, made good power at low boost and kept pulling to 7K

Just has a X-flow BCF3 profile ground onto a Renault GT Turbo blank, it made 235BHP (1400cc) limiter set at 7200 power still going up.

|

NOTE:This user is registered as a LocostBuilders trader and may offer commercial services to other users

|

Volvorsport

|

| posted on 18/12/14 at 01:54 PM |

|

|

a single GT42 would be nice.... external wastegate tho...

search for volvette on you tube , thats a twin turbo SBC .. in a volvo

www.dbsmotorsport.co.uk

getting dirty under a bus

|

|

|

flak monkey

|

| posted on 21/12/14 at 07:47 PM |

|

|

Today I spent around 4 hours turning that big lump of aluminium ^^

Into this - and a whole heap of swarf.

Just need to drill and tap a few holes in it, fit the trigger wheel for the EFI and it'll be done. Might think about getting it anodised at some

point.

It's got grooves for a 5 and 6 rib belt, one each for the alternator and PS pumps. I would normally have figured it out to run a single belt,

but with the electric pump there wasn't really a good place to put an idler and keep everything mounted at the bottom of the block. Either way -

hopefully this will fix the annoying PS belt slip...

Sera

http://www.motosera.com

|

|

|

flak monkey

|

| posted on 8/2/15 at 05:19 PM |

|

|

Finally finished that pulley and fitted it...

I managed to get the steering pump trial fitted and get it lined up with the crank pulley. Had to modify the fluid feed tube, but it's only

pushed into the body of the pump and came out surprisingly easily. I need to add a bend on the end of it toward the inner fender in order to keep the

pipework neat and tidy. The pump came off a 5th gen Camaro, but I think it's the same as fitted to many late model GM cars, but I wanted one

specifically with the multi-rib pulley. I just need to make some proper spacers (1/4" thick) and paint the bracket to finish the

installation.

I didn't get as far as sorting the alternator alignment before it got dark. Really must move the car into the workshop....

Please ignore the rusty engine block.... I'll be fixing that when I swap engines out later in the year. Only I'll be painting the next one

with 2k...!

[Edited on 8/2/15 by flak monkey]

Sera

http://www.motosera.com

|

|

|