Jomac

|

| posted on 27/5/16 at 04:31 PM |

|

|

Chassis mods for a rear engined car

Im just about to start on my build and plan to use a rear engine configuration. This will mean I won't need the transmission tunnel. Is there

any advice other members can give concerning chassis rigidity if I omit this?

a person who makes no mistakes, learns nothing

|

|

|

|

|

Sam_68

|

| posted on 27/5/16 at 04:40 PM |

|

|

quote:

Originally posted by Jomac

Is there any advice other members can give concerning chassis rigidity if I omit this?

Yes, you won't have enough.

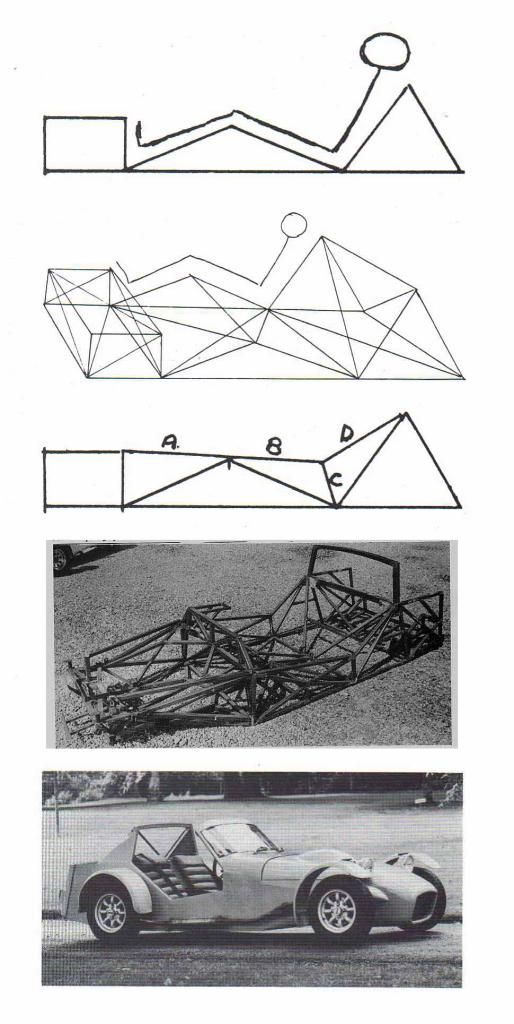

Think about using triangulated 'torsion box' pontoon structures down either side to the cockpit, to replace (and improve upon) the tunnel.

Obviously, you don't need the big hole at the front where the engine used to go, so this can be fully triangulated to form a closed

'box' too (and only needs to be long enough to accommodate the footwells and suspension.

But moving from front to rear engine, you really need to be thinking in terms of a complete, 'clean sheet' design, rather than trying to

adapt the Locost chassis arrangement. Have a look at the Sylva J15 as a reasonable example of how to do it, (though even that can be improved

upon, and it retains a 'tunnel' you'll notice):

|

|

|

big_wasa

|

| posted on 27/5/16 at 05:10 PM |

|

|

Have you seen the Midlana. I've only seen a couple mid / rear engine 7esq cars. The Midlana is probably the best looking and comes as a book

with plans like the original. It is a fairish investment just for a read though.

It uses a full cage.

[Edited on 27/5/16 by big_wasa]

|

|

|

jossey

|

| posted on 27/5/16 at 06:28 PM |

|

|

full cage may solve the ridgidity issue but i wouldnt build a super car on untested chassis builds...

Thanks

David Johnson

Building my tiger avon slowly but surely.

|

|

|

motorcycle_mayhem

|

| posted on 27/5/16 at 07:07 PM |

|

|

I disagree with the previous to some extent, it is possible to get a rigid chassis without extensive construction down the middle.

One need only look at the Sylva Riot to see what is possible, early Riots in particular, didn't have extensive triangulation, later ones did.

Sylva Riots certainly didn't lack rigidity, especially after the adoption of side bars running across the roll hoop to the front scuttle. They

weren't wide, which also helped, the cars weren't designed for the morbidly obese (later ones were), and very well over-engineered without

being too excessive. In my opinion, a delightful piece of simple design.

The MEV Rocket? Correct me if wrong (I usually am, it's an age thing), but I remember seeing that when it came out with not a lot down the

middle - nothing in fact.

Also, unless you're thinking of ruining the thing with an entirely inappropriate engine, something from a 1000cc bike will help packaging and

performance no end.

|

|

|

Sam_68

|

| posted on 27/5/16 at 07:39 PM |

|

|

quote:

Originally posted by motorcycle_mayhem

...it is possible to get a rigid chassis without extensive construction down the middle.

Yes, don't misunderstand me - it certainly is.

Backbone tunnels are structurally efficient in one respect - in that it's easy to fully triangulate them without having big holes to fit engines

and people into - but very inefficient in another - in that they are on the centreline of the vehicle and thus have a poor 'second area

moment'. But the first factor is enough to make them an 'easy win' in terms of stiffness:weight.

And I agree that Sylvas are amongst the most elegantly simple spaceframes on the market (although they are only adequately stiff - nothing

special in absolute terms, or, indeed, in stiffness:weight). But the fact that a conscious decision was made to add more triangulation on later R1ots

should tell you something?

...and if you just omit the tunnel and rely on the simple, 2-dimensional side trellises that are left, you're asking for trouble, as the side

trellises have very little torsional stiffness.

I still think it would be wise, therefore, to use triangulated pontoons if you have the chance.

If you want to be really clever, have a look at Frank Costin's patented 'perfect' spaceframe. This is very structurally

ingenious - far more than it looks at first glance - because it uses a minimal number of tubes to 'stabiise' the 2-dimensional side

trellises and floor, preventing them from cupping or twisting and ensuring that they function efficiently as pure, fully triangulated beams:

|

|

|

JC

|

| posted on 28/5/16 at 01:14 PM |

|

|

Having gone the self design route, you will probably need some sort of tunnel to carry fuel, electricity, hydraulics, water etc. If it's there,

it might as well be structural!

|

|

|

TheGecko

|

| posted on 29/5/16 at 04:06 AM |

|

|

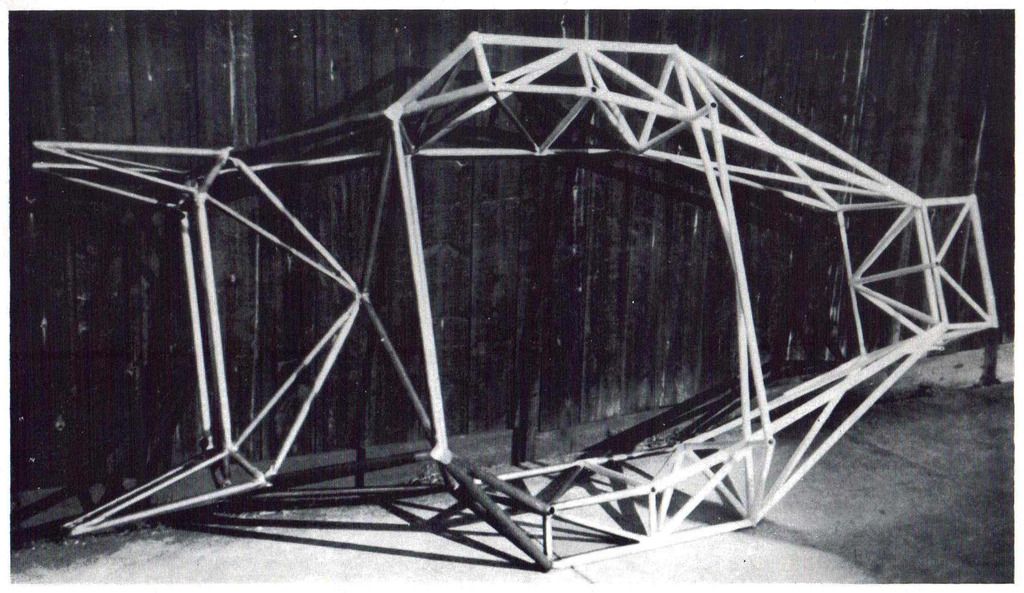

You can read about my middy project in my buikd thread here.

If you look at my chassis as it was being strength tested, you can see where I've added 125mm wide side beams to replace the torsional strength

lost from deleting the centre tunnel.

Hope this is helpful,

Dominic

[Edited on 29/5/2016 by TheGecko]

|

|

|

Neville Jones

|

| posted on 30/5/16 at 03:08 PM |

|

|

The centre tunnel in a 7 does very little for beam or torsion. Anyone who can do the numbers will tell you fairly quickly and somewhere on this forum

is the FEA to prove it as well.

Have a walk down the pitlane at an LMP type event, no tunnels in those. However, they do put substantial structures at the sides, where the material

will do the most good. Polar moments and all that stuff.

The wide side on the Gecko thing is a good halfway solution, but a full box, properly triangulated, will do everything needed. Better still to put a

roll cage around the cockpit, and pick up big amounts of beam and torsion strength.

So, leave out the centre tunnel, it's not needed, but place the material you would have wasted, out on the sides, and enjoy a roomier cockpit.

Cheers,

Nev.

|

|

|

Jomac

|

| posted on 30/5/16 at 03:39 PM |

|

|

Thanks for the interesting info guys, certainly a lot to ponder on. If i had to retain the centre tunnel and use it as suggested for cables etc, i

could be tempted to reduce the height of it a little. I've done some quick calculations and measurements of the donor engine and subframe, and

being a small engine and box (505cc and 20hp) i think i can accommodate the whole unit quite nicely in what is effectively the boot space. I was

hoping for a flat floor as it would be easier to make and give me more room in what would be a smaller car.

a person who makes no mistakes, learns nothing

|

|

|

Sam_68

|

| posted on 30/5/16 at 03:50 PM |

|

|

quote:

Originally posted by Neville Jones

The centre tunnel in a 7 does very little for beam or torsion. Anyone who can do the numbers will tell you fairly quickly and somewhere on this forum

is the FEA to prove it as well.

...leave out the centre tunnel, it's not needed...

That's not correct: and the implication that you could leave out the tunnel and not replace it with pontoon sill structures because

'it's not needed' is very foolhardy indeed.

Certainly, as I explained above, the second area moment of a tunnel is not large enough to represent the most efficient use of material, but

the depth of the structural element is the important factor in beam stiffness and even in torsion, the potential for the perfect, fully

triangulated box section that a backbone tunnel offers can add considerably to the stiffness.

A Lotus Elan backbone chassis on its own (without bodyshell) is stiffer than most 'Seven' spaceframes, and it's folded from

18g sheet. It's light enough to pick up with one hand.

Caterham added a tubular backbone structure (the original Lotus Seven just used a stressed sheet aluminium tunnel) as one of the major advances

on the way from ~950lb.ft/degree to >2,500lb.ft/deg. You can be assured that they didn't add the extra weight and cost for shits and

giggles.

If you're talking about the 'Cymtriks' or Wesley Linton analyses, they prove just the opposite; both rely on reinforcing the

tunnel to achieve a decent level of stiffness, and the Wesley Linton analysis suggests that just fully paneling the tunnel improves overall stiffness

by almost 55% and efficiency by about 38%.

Even with torsion structures for the sills (which I agree is theoretically the best solution, in terms of efficiency), there's still

plenty of structural benefit from a central tunnel, if you design it right.

Edited to add:

If you do decide to add tubular 'pontoon' sill structures, the Costin Lister Jaguar chassis is an interesting example of how it can

be done (without centre tunnel, you'll notice!) on a front-engined roadster that is otherwise similar in arrangement to a

'Seven':

...whether front or rear-engined, what you're trying to achieve (and the reason I said that even the Sylva J15 chassis pictured above could be

improved upon) is 'pontoon' structures that are basically made up of tessellated, well-proportioned tetrahedra.

[Edited on 30/5/16 by Sam_68]

|

|

|

Sam_68

|

| posted on 30/5/16 at 03:53 PM |

|

|

quote:

Originally posted by Jomac...If i had to retain the centre tunnel and use it as suggested for cables etc, i could be tempted to reduce

the height of it a little.

Do bear in mind that - particularly for beam stiffness - reducing the height will substantially reduce the stiffness. If you choose to keep the

tunnel, you should keep it as deep (and as wide) as you can, for maximum benefit.

|

|

|

Neville Jones

|

| posted on 31/5/16 at 08:40 AM |

|

|

'Professor' Sam_68, Martin S seems to know it all.  Though he's not an engineer. Though he's not an engineer.

But he's wrong. Years back, there was a lot of info here about leaving out the tunnel, as I said. Plenty of FEA about as well, other than that

stated. As it is in the book, the tunnel is ineffectual. The height of the side rails has more bearing on beam strength and deflection than anything

the tunnel could ever contribute. Area times distance squared, and all that maths. Torsion...that tunnel is so small, and so close to the centre that

it'd have to be made from 40x40x4 shs, and solidly triangulated to be anywhere near structural, and that's from practical hands on

testing. Build the tunnel from anything smaller, and book size, and you're wasting good metal and precious time. It contributes a small

percentage to beam and torsion.The tunnel can be made from 1.5mm sheet, and often was/is. When you do a torsion test, the sheet can be seen visibly

twisting and distorting.

The cars that do best in the Australian beam and torsion tests, have substantially bigger top and bottom side rails, than Book sizes, and leave the

tunnel as is or even reduced.

Chip Foose was rebuilding a Lotus on the weekend(an old episode), and that chassis could be seen, quite noticeably, twisting as they moved it about.

Chip even commented on it, and extra ali was added. That is just how good a tunnel is, compared with a proper perimeter chassis.

As I said, a cage will add huge amounts of beam and torsion strength, and for a road car, and moreso track, the safety benefits outweigh any other

consideration.

I've been involved in building a good number of customer Locost type cars in the last 30 years, and tested more than a few which were for

export. The 'soft' areas in the book are the untriangulated front panels, and the cockpit. Some solutions are as I posted above.

Not worth arguing further with people who get their knowledge from books and i'net.

Cheers,

Nev.

[Edited on 31/5/16 by Neville Jones]

|

|

|

Sam_68

|

| posted on 31/5/16 at 09:04 AM |

|

|

quote:

Originally posted by Neville Jones

I've been involved in building a good number of customer Locost type cars in the last 30 years

I look forward to you posting photos of all the ones where you omitted the tunnel structure because it's 'not needed' then,

Rod/Rob/Neville/Syd.

Currently in the process of installing a 310bhp supercharged engine in a spaceframe of my design, not following the instructions from a book by

a CDT teacher.

|

|

|

Neville Jones

|

| posted on 31/5/16 at 09:12 AM |

|

|

Tch Tch! Put your handbag away Mrs. Thatcher. Hissy hissy cat claws out.

Do let us know when you're driving this supercharged beast, Martin, so we can keep well away!

Kill yourself, but noone else please.

This thread initially was concerning a chassis for 20hp microcar, then someone started sprouting his i'net knowledge, and info cut and pasted

from the net.

So 99% of what has been said is totally irrelevant.

Hell, a go-kart chassis would be sufficient.

So, Jomac, build your chassis from tubes at least as big as kart tubes, put some sides on to protect yourself at least a little, from side impacts, a

roll bar with braces in case you tip over, and go and have some fun!

[Edited on 31/5/16 by Neville Jones]

|

|

|

Sam_68

|

| posted on 31/5/16 at 09:20 AM |

|

|

quote:

Originally posted by Neville Jones

Tch Tch! Put your handbag away Mrs. Thatcher. Hissy hissy cat claws out.

No, I was being serious, Rod/Rob/Neville/Syd.

The early Lotus Seven used a chassis with nothing more than a bent sheet of aluminium for a tunnel (albeit not delivering modern levels of stiffness),

so I'm sure it would be very instructive and informative for us all to see your proven attempts at putting your money where your mouth is. The

weight saving would be worthwhile.

I'll go further: if you can show me yours, I'll show you mine.

And I bet mine's stiffer.

|

|

|

Neville Jones

|

| posted on 31/5/16 at 09:26 AM |

|

|

That sexual innuendo is not out of place with what the i'net shows about you.

|

|

|

Jomac

|

| posted on 1/6/16 at 11:08 AM |

|

|

Ive been playing with chalk in the driveway...

I marked out the chassis and discovered two things, the first is the chassis is a little long for the size of wheels and the space for the engine. I

either increase the size of the wheels to keep things in proportion, or reduce the size to get the same effect.

The other is the fuel tank. In the original car the tank sits just behind the drivers seat below floor level. The side sills hang down hiding the tank

from view from the side, but with this frame and body the tank would be visible and an eyesore, so i have two choices. I either make a custom tank

that sits in its own frame for protection, in between the drivers seat and the engine, or i mount the tank under the front bonnet, are these

permissable?

a person who makes no mistakes, learns nothing

|

|

|

gremlin1234

|

| posted on 1/6/16 at 03:27 PM |

|

|

quote:

are these permissable?

I think the next thing you have to do is get a copy of the sva/ iva manuals,

car iva (M1) and bike/trike/quad MSVA

available from:

https://www.gov.uk/vehicle-approval

|

|

|