Slimy38

|

| posted on 20/9/19 at 08:30 AM |

|

|

Pipe bender dimensions

Time for a really basic engineering question if I may. I'd like to have a go at 3d printing a pipe bender for 3/16" brake pipe. The main

part will be the roller that forms the bend. If the pipe is 3/16", what radius should I use on the roller? Should it be 3/16" or is there

a rule for the amount of tolerance required?

Along the same lines, is there a minimum bend radius that can be applied?

I would like to understand the theory behind both measurements, if someone has a link to a suitable web page explaining pipe bending that would be

brilliant.

|

|

|

|

|

voucht

|

| posted on 20/9/19 at 08:57 AM |

|

|

Hi,

I Can't answer about the bender radius, but I can about the minimum radius for brake pipes. For copper, copper-nickel or steel pipes we sold in

the motorsport hydraulic company I used to work for, the minimum bend radius is 8mm for 3/16'' pipes.

Now, when I have a look at the pipe benders we sold, the smallest one for 3/16'' pipe has a bend radius of 10mm.

Hope that will help

555

|

|

|

Slimy38

|

| posted on 20/9/19 at 09:08 AM |

|

|

Thanks for the information, it's appreciated. I think 10mm is a good starting point, it's actually a good deal tighter than I expected so

I might go for a larger radius just to make things a bit easier for myself.

|

|

|

907

|

| posted on 21/9/19 at 07:20 AM |

|

|

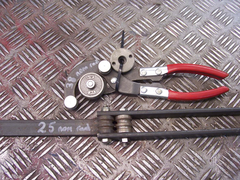

I bought a pipe bender that had a nominal radius of 19mm ( 1.5" dia ) but wouldn't do bends close to each other, so I made one with a 25

nominal diameter.

When you bend pipe the inside wall thickness stays more or less the same while the outside wall thins, depending on how tight the radius is.

If you work out the distance round the inside dia, and the distance round the outside dia, then the percentage difference will be the percentage

thinning that will occur. Based on this you then choose what radius & % thinning is acceptable.

My home made bender gives a nominal ( or centre line ) radius of 12.5mm and did the Suttol brake ( 3/16" ) and clutch pipes. ( 1/4" ) (

see pic )

Paul G

Description

[Edited on 21/9/19 by 907]

|

|

|