Fred W B

|

| posted on 7/1/08 at 06:23 PM |

|

|

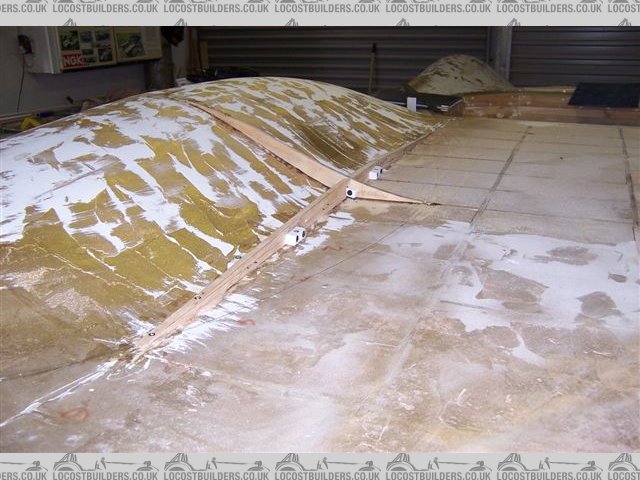

Here you can see that at this point I determined that I had had to bring the highest point of the RHS front wheel arch hump up another 3 mm.

[img][/img]

You can do it quickly. You can do it cheap. You can do it right. – Pick any two.

|

|

|

|

|

Fred W B

|

| posted on 7/1/08 at 06:24 PM |

|

|

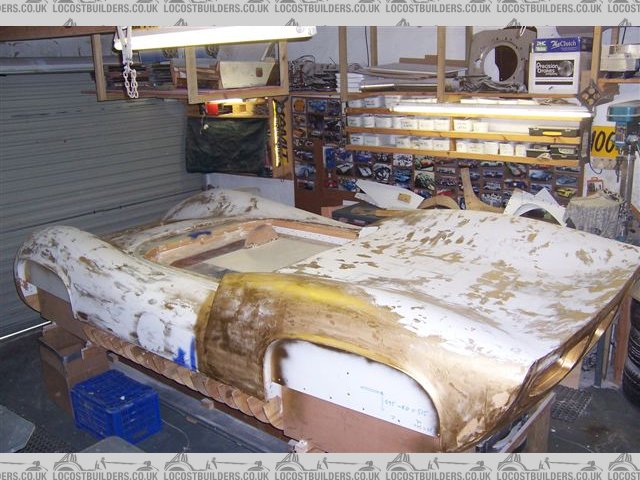

Have now started adding a bit more "fat" to the rear wheel arch humps towards the center of the rear deck.

Finally starting to feel I have now broken the back of most the body shaping.

Cheers

Fred W B

bb 0290

bb 0300

[Edited on 7/1/08 by Fred W B]

You can do it quickly. You can do it cheap. You can do it right. – Pick any two.

|

|

|

Ivan

|

| posted on 7/1/08 at 08:54 PM |

|

|

Fred - watching your progress amazes me - you are certainly going for perfection and getting there.

It reminds me of an old work colleage (a surveyor believe it or not) who's favourite expression was "we are not grinding crankshafts

here" as an excuse for mediocre quality work or taking shortcuts, and in many cases it was valid. However that definitely doesn't apply to

what you are doing and I am sure that your "grinding of the crankshaft" will show in the end result.

Keep up the good work - you are an insperation to many of us.

|

|

|

Fred W B

|

| posted on 9/1/08 at 07:17 PM |

|

|

thanks Ivan

I use the expression "this is not a space shuttle" quite a bit

Cheers

Fred W B

You can do it quickly. You can do it cheap. You can do it right. – Pick any two.

|

|

|

violentblue

|

| posted on 10/1/08 at 03:38 AM |

|

|

WOW, i check for updates on your project every time i visit these forums. I'm always impressed.

a few pics of my other projects

|

|

|

sgraber

|

| posted on 10/1/08 at 05:22 AM |

|

|

That is cracking me up! I use the phrase "we aren't sending a man to the moon" all the time!

But seriously Fred, you are really going the extra mile. And I just know you are having a great time doing it! Fun! Hard, but fun.

quote:

Originally posted by Fred W B

thanks Ivan

I use the expression "this is not a space shuttle" quite a bit

Cheers

Fred W B

Steve Graber

http://www.grabercars.com/

"Quickness through lightness"

|

|

|

Dom9

|

| posted on 10/1/08 at 09:53 AM |

|

|

Hi Fred, I have hovered on this forum for quite a while but have spent the last few years working away from home. So I never signed up here or indeed

had the space to work on my own project.

I was offered a Group C Jaguar XJR-9 body in GRP a few years back, but I had to move house and so couldn't commit to the project and I also

remember in one of the UK kit car mags a few years ago, another Group C/ Le Mans style body in GRP being sold for only £600 if memory serves

correct...

I haven't seen anything (except maybe the Ultima) like that for a long time and so I have been thinking a lot about getting a nice, authentic

die-cast model in say 1/10th scale and having it drawn up in AutoCAD (my missus, Lou, is a CAD draughy) and make the plug exactly as you have done in

the garage.

I would really love to design the whole car, from spaceframe and suspension through to bodywork and own my own Group C/ Le Mans/ IMSA GTP replica!

This thread is a real inspiration as is Andygtt's work, which I have followed (quietly) on Pistonheads since he first posted there. The only

thing that scares me is the cost and the time involved... Despite being an engineer in the oil and gas industry, having previously worked for Lotus

and Ferrari, I would still be worried about trying to build a body from scratch.

If we are ever in town, and I have promised Lou we will go to SA soon as my grandparents were from Cape Town, I would love to come and see the work

you have done.

Hopefully I will have the time and passion to do what you and Andy have done, over the next few years.

|

|

|

Fred W B

|

| posted on 10/1/08 at 06:27 PM |

|

|

HI Dom

Thanks for your post. I would be very pleased to show you what I am doing, if you ever end up in Port Elizabeth. If you are planning a trip to SA,

driving by road from PE to Cape Town (or visa versa), via Kynsna is reccomended.

Anything is possible, if you persevere. As an engineer you already have the problem solving skills required. Before I started this, I had no practical

experience in any car designing or composite building skills.

As I said in another post a while ago, once I've decided what I want to do I:

Find out how to do it - books, internet, speak to people.

Get what I need to do it - tools, materials.

Start doing it!

Solve one problem at a time.

If you get stuck do something else for a while, then go back to it.

So just go for it

Cheers

Fred W B

[Edited on 10/1/08 by Fred W B]

You can do it quickly. You can do it cheap. You can do it right. – Pick any two.

|

|

|

Fred W B

|

| posted on 10/1/08 at 06:34 PM |

|

|

[img][/img]

You can do it quickly. You can do it cheap. You can do it right. – Pick any two.

|

|

|

TheGecko

|

| posted on 11/1/08 at 03:31 AM |

|

|

quote:

Originally posted by Fred W B

Anything is possible, if you persevere. As an engineer you already have the problem solving skills required.

This brings to mind the quote attributed to Nevil Shute who, as well as being a notable author,

was firstly an aeronautical engineer. He said:

"An engineer is a man who can make something for five bob that any bloody fool can make for a quid!"

I agree wholeheartedly with Fred's thoughts here. Knowledge of the technical details of building a car are less important than the mindset

necessary to enable you to acquire that knowledge.

I suspect that some people enjoy the problem solving aspect as much as (or maybe even more than) driving the finished product.

Dominic

|

|

|

Peteff

|

| posted on 11/1/08 at 11:17 AM |

|

|

I like Monty Burns' saying in the Simpsons " Good grief man,this is brain surgery, it's not rocket science " You'll see

the shape more when it's all one colour but it looks good so far.

yours, Pete

I went into the RSPCA office the other day. It was so small you could hardly swing a cat in there.

|

|

|

Fred W B

|

| posted on 10/2/08 at 11:08 AM |

|

|

So now we have bigger hips...........

feb 006

feb 008

[Edited on 10/2/08 by Fred W B]

You can do it quickly. You can do it cheap. You can do it right. – Pick any two.

|

|

|

Fred W B

|

| posted on 10/2/08 at 11:14 AM |

|

|

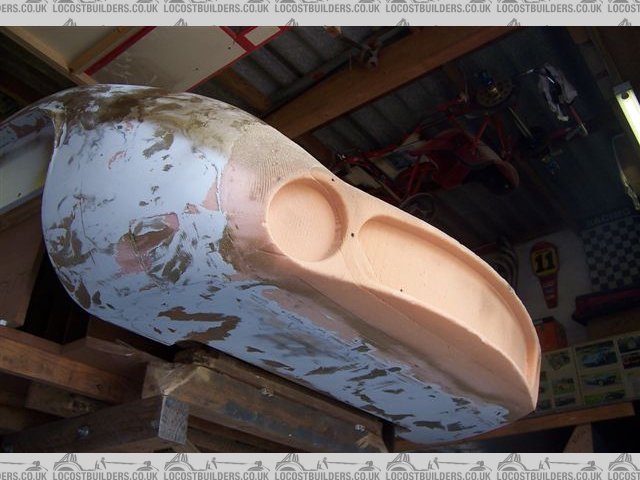

Here you can see how much material I added when reworking the nostrils.

feb 001

Now just need the edge radii formed

feb 022

[Edited on 10/2/08 by Fred W B]

You can do it quickly. You can do it cheap. You can do it right. – Pick any two.

|

|

|

Fred W B

|

| posted on 10/2/08 at 11:17 AM |

|

|

As always the devil is in the detail and the smallest things always seem to take forever. Here I am forming the windscreen recess

feb 108

feb 024

feb 025

[Edited on 10/2/08 by Fred W B]

You can do it quickly. You can do it cheap. You can do it right. – Pick any two.

|

|

|

Fred W B

|

| posted on 10/2/08 at 11:23 AM |

|

|

Looking back up the thread I see I have been reworking for 7 months now. But finally I am happy with the major details of the shape

Cheers

Fred W B

feb 012

feb 013

[Edited on 10/2/08 by Fred W B]

You can do it quickly. You can do it cheap. You can do it right. – Pick any two.

|

|

|

RK

|

| posted on 10/2/08 at 03:01 PM |

|

|

How much is 5 bob?

|

|

|

Kaspa

|

| posted on 10/2/08 at 06:44 PM |

|

|

1 quid = 1 pound. or 20 shillings in old pre decimal curreny

5 bob = 5 shillings

not a lot

Kaspa

understeer= when you hit the wall front first

oversteer=when you hit the wall back first

HP= how fast you hit the wall

Torque= how far the wall moves when you hit it

|

|

|

Fred W B

|

| posted on 14/3/08 at 11:30 AM |

|

|

Struggling with my motivation a bit at the moment, and have had a few other things to do. Haven't touched the car in a month.......

Cheers

Fred W B

You can do it quickly. You can do it cheap. You can do it right. – Pick any two.

|

|

|

Delinquent

|

| posted on 14/3/08 at 11:46 AM |

|

|

quote:

Originally posted by Fred W B

Struggling with my motivation a bit at the moment, and have had a few other things to do. Haven't touched the car in a month.......

Cheers

Fred W B

Think there must be a bug going around - virtually everyone I know that has a project running at the moment seems to be down on enthusiasm!

|

|

|

Fred W B

|

| posted on 13/4/08 at 09:30 AM |

|

|

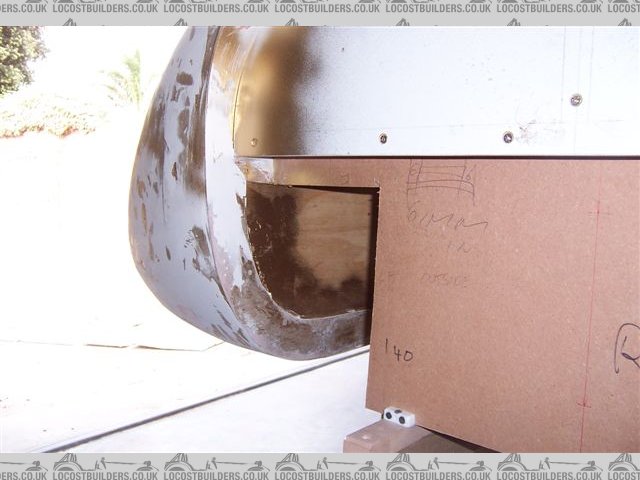

Enough! Foam and preskinning filler work finally finished. Just completed shaping the front lower edges of the front wheel arches and the surface

under the nose. Working overhead while lying on your back is not fun!

Now just radiusing a last few edges and then I can start with laying on the grp skin and the real surfacing.

Cheers

Fred W B

nose 55

nose 049

nose 50

nose 51

[Edited on 13/4/08 by Fred W B]

You can do it quickly. You can do it cheap. You can do it right. – Pick any two.

|

|

|

Delinquent

|

| posted on 13/4/08 at 12:17 PM |

|

|

Congrats Fred, a milestone reached - and a bloody good looking one at that

|

|

|

autohausdolby

|

| posted on 14/4/08 at 08:19 PM |

|

|

Awesome thread

|

|

|

ghetto_eddie

|

| posted on 16/4/08 at 03:28 PM |

|

|

Fred,

I am building a body in a very similar way to you... even down to the little KD (modesty/whatever you call them) blocks holding the ply together..

But one big question... how the hell did you secure yours together? i started to assemble my buck the other day and realised my drill is too big and

hence doesnt fit in enough for me to sink the final screw (of the 3) in the blocks!

My only solution so far is a 90degree drill adapter... but would be interested to see how you got on with this!

Regards

Edd

|

|

|

Fred W B

|

| posted on 16/4/08 at 03:42 PM |

|

|

Hi Eddie

I made sure that I worked from the first station outwards, so you were always working away from the previous panel. Secure that panel, then move onto

the next. You have to think the assembly process through to ensure you can get in where necessary. Put all the joiners on a panel before you add it to

the buck where possible for example.

Where I sometimes had to go back in, I had to cut away the second panel back enough to get a short battery operated pistol grip style screwdriver in.

Or some times I could use a very long adaptor made up from 1/4" drive socket set bits, through access holes drilled in the stations etc etc.

Use a large "spade" drill

All the best with your project

Cheers

Fred W B

[Edited on 16/4/08 by Fred W B]

[Edited on 16/4/08 by Fred W B]

You can do it quickly. You can do it cheap. You can do it right. – Pick any two.

|

|

|

ghetto_eddie

|

| posted on 16/4/08 at 04:11 PM |

|

|

Thankyou Fred for the quick and helpful reply!

I shall see tonight if my 90 degree adaptor idea will fit in... if not i shall procede with the method you outlined above!

All the consideration i put into this build... and i overlook the smallest of things!

Edd

|

|

|