Gakes

|

| posted on 11/1/08 at 04:22 PM |

|

|

Locost based middy, plan to use subaru ej20 engine

Hi everyone, greetings from down below  , South Africa, Cape Town. I love what you guys and gals are doing. , South Africa, Cape Town. I love what you guys and gals are doing.

This is my first time posting on this forum, I've been reading all the middy posts for a while now. I chose this project for my final year of

study in industrial design. I know this is crazy, the car must be done in 4 1/2 months. I have designed most of the chassis and I've come up

with a design for the body already.

I am looking for the dimensions of the EJ20, Subaru engine, and I was wondering which gearbox I can use as a 2wd box. I saw a post on welding up the

internals of the 4wd box for RWD but not sure if it will work for front wheel drive.

Has anyone else done a scooby based middy succesfully?

Heres my concept design, my chassis design is on my other PC, I'll post it tomorrow:

Description

|

|

|

|

|

zzr1100rick2

|

| posted on 11/1/08 at 04:34 PM |

|

|

Why not use the 2wd gearbox as its slightly shorter than the 4wd one

ho idea as to dimensions use to work on them but never measured one

|

|

|

iank

|

| posted on 11/1/08 at 04:46 PM |

|

|

Welcome.

Only Scooby based middy I've come across is the "Saker GT" http://www.saker.co.nz/ though I don't know which exact engine it

uses.

On your project 4.5 months is very aggressive to get a body made as well as the mechanicals. See "Fred W B" "Gaz 1977" and

"sgraber" posts which should help a lot as a start. On the positive side it isn't the most complex shape (in a good way - I quite

like it from that angle) which makes life a lot easier. Do you have lights in mind or will you be fabricating/faking some?

There is a Subaru 2wd gearbox but it's not as common obviously.

--

Never argue with an idiot. They drag you down to their level, then beat you with experience.

Anonymous

|

|

|

RazMan

|

| posted on 11/1/08 at 04:46 PM |

|

|

quote:

Originally posted by Gakes

I saw a post on welding up the internals of the 4wd box for RWD but not sure if it will work for front wheel drive.

Some of this was discussed quite recently here but are you sure about a front

wheel drive middy?

[Edited on 11-1-08 by RazMan]

Cheers,

Raz

When thinking outside the box doesn't work any more, it's time to build a new box

|

|

|

Gakes

|

| posted on 11/1/08 at 04:58 PM |

|

|

Thanks for the swift replies guys.

zzr1100rick2 and iank Contributor

: I heard bout a 2wd box but I'm not sure if it will fit.

I planned to make the body out of hemp and a plant based epoxy resin.

RazMan Contributor: That post dont have any dimensions

Description

|

|

|

Gakes

|

| posted on 11/1/08 at 05:08 PM |

|

|

OOOOOH, i just went through the "Subaru Powered Midy/Thoughts?" post and saw that the gearboxes look exactly the same except for the end

section that probably houses the centre diff.

Its not a FWD middy, its the subaru drivetrain's front section without the prop

[Edited on 11/1/08 by Gakes]

Description

|

|

|

iank

|

| posted on 11/1/08 at 05:14 PM |

|

|

quote:

Originally posted by Gakes

...

I planned to make the body out of hemp and a plant based epoxy resin.

...

You eco-warrior you  no idea about that as a material, but the I guess you still need a negative mould, so therefore a buck i.e. a full size car

body made of wood/chickenwire/polystyrene/plaster - or whatever will be needed to model the final shape and pull the moulds from. It's that bit

that takes the time if you want/need a quality final body. no idea about that as a material, but the I guess you still need a negative mould, so therefore a buck i.e. a full size car

body made of wood/chickenwire/polystyrene/plaster - or whatever will be needed to model the final shape and pull the moulds from. It's that bit

that takes the time if you want/need a quality final body.

--

Never argue with an idiot. They drag you down to their level, then beat you with experience.

Anonymous

|

|

|

Gakes

|

| posted on 11/1/08 at 05:22 PM |

|

|

quote:

You eco-warrior you no idea about that as a material, but the I guess you still need a negative mould, so therefore a buck i.e. a full size car body

made of wood/chickenwire/polystyrene/plaster - or whatever will be needed to model the final shape and pull the moulds from. It's that bit that

takes the time if you want/need a quality final body.

"eco warrior" , good1 , good1

Its basically the same process as making a glass-fibre body, I'm just using hemp fibres instead. This is why the body is so simple, its divided

into a front,back and two sides. The car is planned to be more then 95% recyclable and/or ground into biodegradeable grains/dust.

Quite optimistic , I know. but I'm sure its a good learning curve , I know. but I'm sure its a good learning curve

Description

|

|

|

Ivan

|

| posted on 11/1/08 at 05:41 PM |

|

|

If you want the dimensions of a Subie motor there are several importers of used motors in Cape Town who normally have Subie motors in stock and who

would be happy to let you measure one up.

|

|

|

Gakes

|

| posted on 11/1/08 at 05:48 PM |

|

|

quote:

Ivan

If you want the dimensions of a Subie motor there are several importers of used motors in Cape Town who normally have Subie motors in stock and who

would be happy to let you measure one up.

Thanks for the suggestion, fellow South African I'll go around tomorrow morning I'll go around tomorrow morning

Description

|

|

|

meany

|

| posted on 11/1/08 at 09:32 PM |

|

|

if you need any measurements, just give me a shout.

not sure what i have in my photo archive.

look in "misc"

[Edited on 11/1/08 by meany]

|

|

|

Gakes

|

| posted on 12/1/08 at 06:50 PM |

|

|

Thanks Meany.

All hail Meany   You rock dude! You rock dude!

Description

|

|

|

Gakes

|

| posted on 13/1/08 at 10:31 AM |

|

|

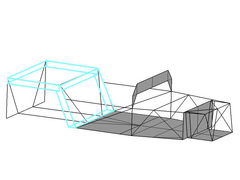

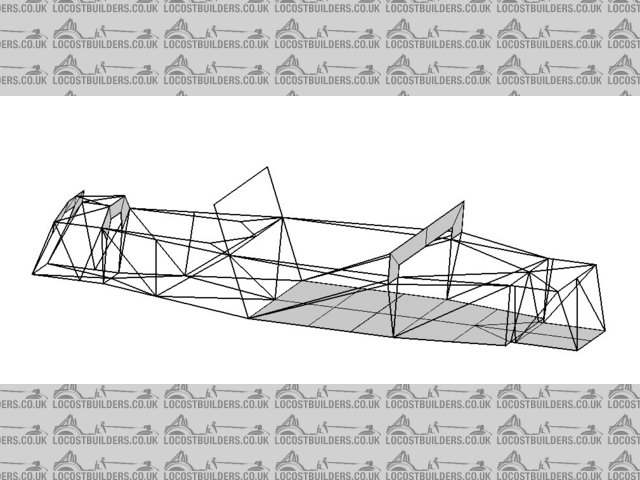

Here's a few pics of my chassis, some constructive criticism will be much appreciated:

[img][/img]

Description

|

|

|

RazMan

|

| posted on 13/1/08 at 10:53 AM |

|

|

I'm no expert, but I am sure that you will need a LOT more triangulation in that design.

Cheers,

Raz

When thinking outside the box doesn't work any more, it's time to build a new box

|

|

|

Fred W B

|

| posted on 13/1/08 at 01:04 PM |

|

|

Hi gakes, nice to see another Sa on here

You might like to check out

this thread

and

this thread

Cheers

Fred W B

[Edited on 13/1/08 by Fred W B]

You can do it quickly. You can do it cheap. You can do it right. – Pick any two.

|

|

|

cymtriks

|

| posted on 13/1/08 at 01:23 PM |

|

|

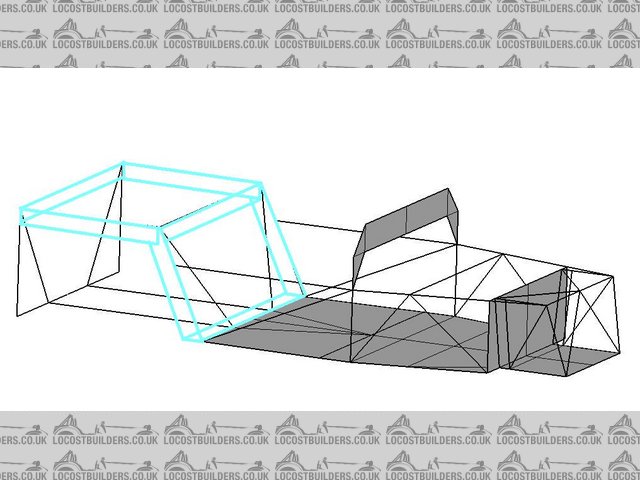

better chassis

OK,

The tunnel is probably doing nothing for the chassis, in fact the whole chassis isn't going to do much for the chassis until you put in some more

triangulation!

A front like the one on this would be a lot better. The blue lines show the bigger 4x2 14 gauge tubes around the engine bay. A spaceframe rear is

certainaly possible.

Rescued attachment pic2-4x2.JPG

|

|

|

cymtriks

|

| posted on 13/1/08 at 01:27 PM |

|

|

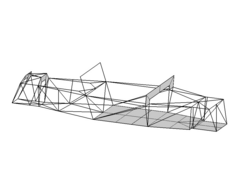

Another one

Or a variation of this perhaps?

Rescued attachment snapshot23.jpg

|

|

|

Gakes

|

| posted on 13/1/08 at 02:11 PM |

|

|

Thanks for the advice guys  , I was going to add a few cross members into the design, but its still a "work in process" project. I have

another idea that could probably work much better with less tubing. I'll get cracking and post something later. , I was going to add a few cross members into the design, but its still a "work in process" project. I have

another idea that could probably work much better with less tubing. I'll get cracking and post something later.

Description

|

|

|

Gakes

|

| posted on 13/1/08 at 03:36 PM |

|

|

does anyone have the track width that goes with the EJ20

Description

|

|

|

Gakes

|

| posted on 13/1/08 at 03:37 PM |

|

|

does anyone have the track width for the ej20?? Meany do you perhaps have those details please

[Edited on 13/1/08 by Gakes]

Description

|

|

|

Gakes

|

| posted on 21/1/08 at 09:16 PM |

|

|

Description

|

|

|