bi22le

|

| posted on 26/3/11 at 08:16 PM |

|

|

Sump shortening and baffle advice please

Hi all,

So onto my next mod.

I have a second sump that I will be shortening and baffling. This is only being done because the sump to floor distance is far to close for my

conscience!

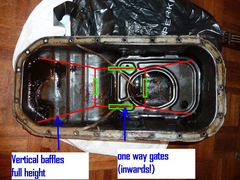

So I will be whipping about 40mm of the bottom. See below pics

Stock sump top modified

Above picture shows the 4 segments im looking for and a simple method of preventing the oil from getting away. I will be installing gates (doors or

flaps, what ever you want to call them) to allow oil to flow into the centre section but not out. The height of the diagonals will be full height (to

the bottom of the stock Windage tray) but the centre square will be slightly lower to allow oil to flow over the top. This is so the centre section

dont over fill too much.

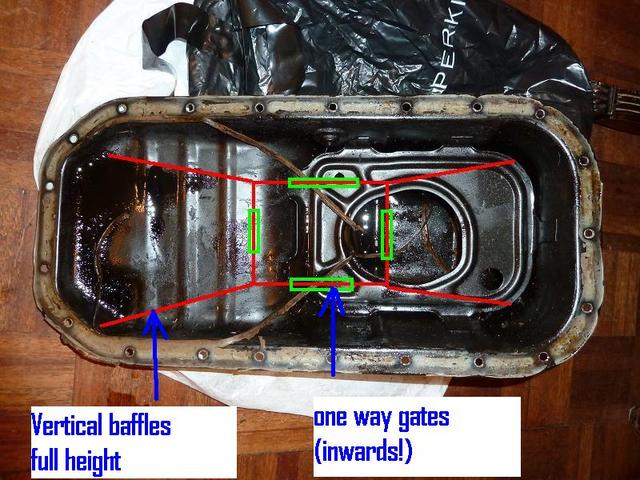

Stock sump side modified

Above picture shows side profile. This has tapered edges to allow flow and drainage.

I understand there are probably many different ways to reduce height, increase capacity and prevent unwanted flow. One thing to do is to rearrange the

vertical baffles and change gates for holes.

Oh the other thing is that I have heard that you have to be careful not to warp the top section of the sump or a tight seal can not be made. Has

anybody heard of this before. I have no spare block to bolt to during welding. Any neat tricks or ideas? The pro welders at my work will be doing it

so the welds should be amazing.

Whats peoples thoughts?

Thanks

Biz

[Edited on 26/3/11 by bi22le]

Track days ARE the best thing since sliced bread, until I get a supercharger that is!

Please read my ring story:

http://www.locostbuilders.co.uk/forum/13/viewthread.php?tid=139152&page=1

Me doing a sub 56sec lap around Brands Indy. I need a geo set up! http://www.youtube.com/watch?v=EHksfvIGB3I

|

|

|

|

|

jacko

|

| posted on 26/3/11 at 09:37 PM |

|

|

To stop them warping i screw the sumps down to my work bench

And don't just weld it all the way round do small welds a bit here a bit there so it don't get to hot

What engine is your sump for ?

[Edited on 26/3/11 by jacko]

|

|

|

mark chandler

|

| posted on 26/3/11 at 11:10 PM |

|

|

Why are you doing vertical baffles, this just keeps oil in the wrong place!

Horizontal baffles keep the oil down by the pickup, this is what you want.

|

|

|

bi22le

|

| posted on 26/3/11 at 11:23 PM |

|

|

Its for a AE111 (Blacktop 20V 4age)

I kind of get what your saying Mark but surly horizontals just stop the oil getting to the pickup. Im under the understanding that the verticals will

prevent it sloshing around and the gates will allow the oil to flow towards the pickup only.

Any other thoughts??

Cheers,

Biz

Track days ARE the best thing since sliced bread, until I get a supercharger that is!

Please read my ring story:

http://www.locostbuilders.co.uk/forum/13/viewthread.php?tid=139152&page=1

Me doing a sub 56sec lap around Brands Indy. I need a geo set up! http://www.youtube.com/watch?v=EHksfvIGB3I

|

|

|

alawrence

|

| posted on 27/3/11 at 05:56 AM |

|

|

sump

http://www.toyne.org.uk/kc-mods-sumpchop.html

have you seen this ?

|

|

|

bimbleuk

|

| posted on 27/3/11 at 06:55 AM |

|

|

Here's the two sump designs which were fitted to that very same engine before I sold the car to you.

The first three are of the BPJ Services large capacity cast sump. To put it bluntly it was overly engineered, heavy and not adequately baffled IMHO.

There's nothing to stop the oil rising up out of the central chamber. The windage plate which sits above (but not shown) is not sufficient.

Unfortunately I bought that sump before I did any proper research into sump design.

So after that I got RAW to make me a sump to my design which addressed the problem of oil staying at the periphery of the sump. Toyota had actually

made a pretty good sump design to start with so all I was doing really was addressing the ground clearance in a kit car. Everything from the

horizontal plate upwards is original Toyota, below that is modifed. So the last two pictures are of the sump RAW ended up making. The lower chamber

traps oil below the horizontal plate. There is a vertical lip around the edge of the hole to stop oil easily rising up and the original sump sides are

acting as vertical baffles (not visible) in the sump with holes to allow oil flow.

That was my orginal design. If I was to improve on it I would raise the horizontal plate. Make it slop towards the centre hole in the middle and

reduce the size of the hole so you can just squeeze the pickup pipe & filter through it. Maybe put trap doors in the vertical baffles in the lower

section of the sump.

RAW liked it and use it to offer a sump mod service for about £130 rather than the £300-400 for their steel copy of the BPJ sump.

BPJ Sump 1

BPJ 2

BPJ 3

Shortened sump

Baffled sump

[Edited on 27-3-11 by bimbleuk]

|

|

|

mark chandler

|

| posted on 27/3/11 at 11:45 PM |

|

|

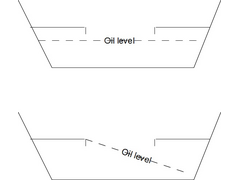

Horizontal baffles need seam welding around the outside, oil can then only slosh up as high as the baffle then falls back. For the hole where the

pickup drops press the hole in so you end up with a lip facing down, do this for any extra drain holes as it helps keep the oil where its needed.

Baffle

You can prove this easily enough, get a plastic tub, cut some vertical baffles and drop in then fill with water, give it a shake and water will spash

out and stay in local areas, a bad thing!

Next remove the vertical baffles, clip on the lid and cut a hole in the middle of the lid, now fill with water and shake, like a babies potty, you

will find to hard to slash out the water!

The baffle needs to be no more than 1/2" above the running oil level in the sump, this makes sure when cornering hard the oil will fill the side.

second drawing shows the oil forced up the side.

Regards Mark

|

|

|

bi22le

|

| posted on 28/3/11 at 12:39 PM |

|

|

Thanks for the infor Mark and Justin, I think the Horizontals are abit more cruicial than first throught.

Justin, how much did your design (second sump) reduce the depth of the sump by becasue it dont look like that much?

I was hopeing to loose about 40mm in height. I also wanted to take advantage of the shallow reat section to gain back my volume instead of branching

sidways. Did you decide not to do this so that the car would not starve under acceleration?

Mark, good point about the vertical lips on horizontal plates. Ill try and integrate that into my design.

So I am now still thinking along the mines of my original design, the cross and square vertical baffle layout seems proven with gates.

The other unanswered quesiton still is regarding the warping of the sump during welding. As previously said, is it just a case of spot welding it and

taking you time not to heat it up too much? Maybe lots of G clamps to a metal desk would help.

Any other thoughts, improvments or ideas.

Cheers,

biz

Track days ARE the best thing since sliced bread, until I get a supercharger that is!

Please read my ring story:

http://www.locostbuilders.co.uk/forum/13/viewthread.php?tid=139152&page=1

Me doing a sub 56sec lap around Brands Indy. I need a geo set up! http://www.youtube.com/watch?v=EHksfvIGB3I

|

|

|

mark chandler

|

| posted on 28/3/11 at 10:36 PM |

|

|

Little welds and leap all over the sump so it all gets hot at the same time, running a long bead is asking for trouble which is a pity as stop start

leads to pin holes

Screw it to something solid anyway when welding from the outside, bit of thick ply will do.

[Edited on 28/3/11 by mark chandler]

|

|

|

FASTdan

|

| posted on 29/3/11 at 06:26 AM |

|

|

I think both horizontal and vertical baffles are required plus gating as you have shown.

A few pics of our duratec one can be seen here:

http://www.locostbuilders.co.uk/viewthread.php?tid=127607

First time round it wasn't sufficient, we still had surge on hard braking and brief pressure drops. Basically I had left too much clearance

around the edges of the baffle plates (I was concerned about too little flow TO the pickup). I filled in around the edges and some of the holes and it

was bang on, no surge from 120-20mph braking on track or at any other time.

I did as said and filled it with water and sloshed about a bit to check the gates etc, quite interesting to watch the flow. This does show how

important the horizontal is - the amount of water that would pass upwards through the pickup pipe hole was surprising.

NEW danST WEBSITE NOW LIVE! Bike carbs, throttle bodies and more......

http://www.danstengineering.co.uk/

|

NOTE:This user is registered as a LocostBuilders trader and may offer commercial services to other users

|

Dopdog

|

| posted on 7/6/12 at 07:46 PM |

|

|

I keep looking at this post for reference and have noticed that the sump you have in your mod pictures is for a 16v 4age engine not the 20v. If you

look at bimbles picture it does not have a straight edge on one side.

to add to this I think I have found new sumps in the states for around $70, will confirm once I have all the info.

Simon

|

|

|