MK9R

|

| posted on 15/12/09 at 04:17 PM |

|

|

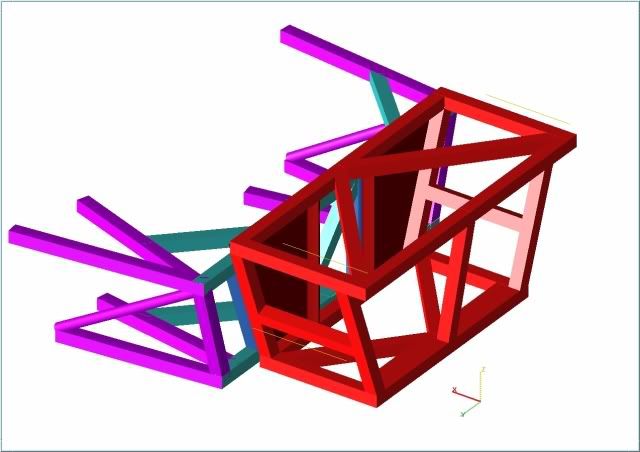

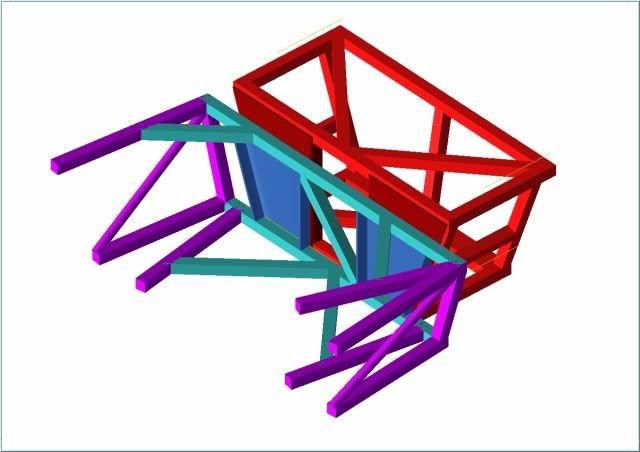

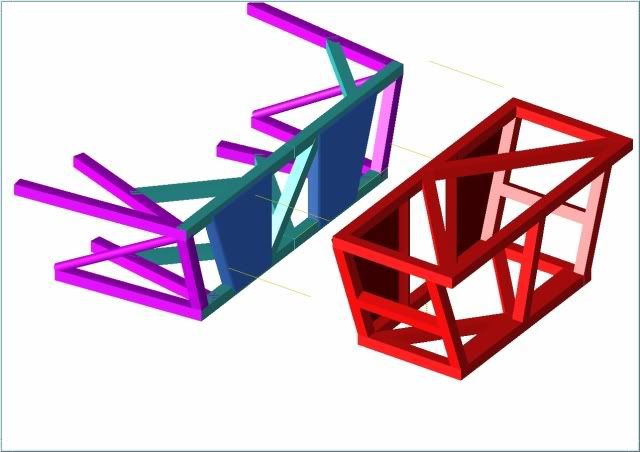

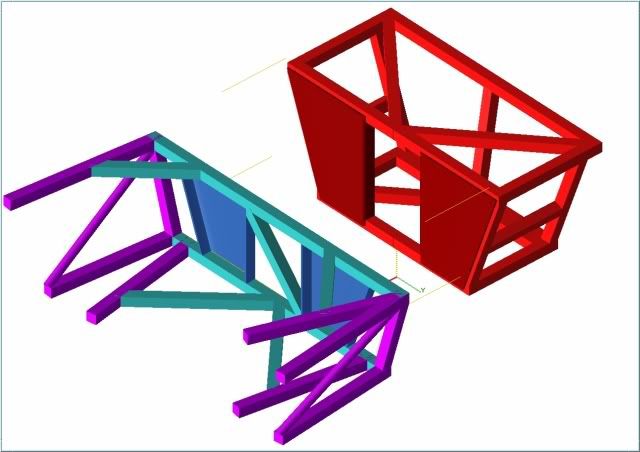

Bolt on front end subframe

Thinking of replacing the front end of the chassis with a bolt on subframe so easily changeable after a racing incidents, and/or develop suspension.

The plate between the existing chassis and subrame would be 5mm, bolted together with M12 and doweled.

Magenta = existing Fury Chassis

Cyan = added members to chassis

Red = bolt on front end

yellow lines are pick up points for suspension.

Note, the steering rack mounts and damper mounts are not shown

The reason the front subframe is higher is because its a racing chassis so has the raised suspension points and i want them to mount direct to the

chassis rail

What do you think?

[Edited on 15/12/09 by MK9R]

Cheers Austen

RGB car number 9

www.austengreenway.co.uk

www.automatedtechnologygroup.co.uk

www.trackace.co.uk

|

|

|

|

|

thunderace

|

| posted on 15/12/09 at 04:27 PM |

|

|

Magenta Cyan wtf are they lol

|

|

|

Staple balls

|

| posted on 15/12/09 at 04:32 PM |

|

|

quote:

Originally posted by thunderace

Magenta Cyan wtf are they lol

Colours

|

|

|

MikeRJ

|

| posted on 15/12/09 at 04:33 PM |

|

|

The 5mm plates seems unnecessarily large and heavy. Something like a small bit of 3mm plate would likely suffice if you could create a rigid mounting

area with box sections.

Perhaps you could make the cyan parts out of wider box so you could weld in some mounting bosses/dowel locators and ditch the big plates entirely?

|

|

|

TimC

|

| posted on 15/12/09 at 04:37 PM |

|

|

quote:

Originally posted by thunderace

Magenta Cyan wtf are they lol

A comment there from someone who clearly never had a CGA monitor. This used to be it - the only colours you could see on a PC!

|

|

|

MK9R

|

| posted on 15/12/09 at 04:39 PM |

|

|

quote:

Originally posted by MikeRJ

The 5mm plates seems unnecessarily large and heavy. Something like a small bit of 3mm plate would likely suffice if you could create a rigid mounting

area with box sections.

Perhaps you could make the cyan parts out of wider box so you could weld in some mounting bosses/dowel locators and ditch the big plates entirely?

Good point, could use 50mmx25mm box with crush tubes

Cheers Austen

RGB car number 9

www.austengreenway.co.uk

www.automatedtechnologygroup.co.uk

www.trackace.co.uk

|

|

|

Mr G

|

| posted on 15/12/09 at 04:44 PM |

|

|

quote:

Originally posted by TimC

quote:

Originally posted by thunderace

Magenta Cyan wtf are they lol

A comment there from someone who clearly never had a CGA monitor. This used to be it - the only colours you could see on a PC!

Or someone who owned a ZX spectrum

Normal is getting dressed in clothes that you buy for work and driving through traffic in a

car that you are still paying for - in order to get to the job you need to pay for the clothes

and the car, and the house you leave vacant all day so you can afford to live in it.

|

|

|

adithorp

|

| posted on 15/12/09 at 05:02 PM |

|

|

Can't see why not. Adds a bit of weight but if done right will add stiffness. If you put in dowels to locate it accuratly, you could

remove/refit without having to recheck the suspension. Or you could have another front sub-frame complete and set up and just swap them over should

you ever have damage at a meeting.

adrian

"A witty saying proves nothing" Voltaire

http://jpsc.org.uk/forum/

|

|

|

blakep82

|

| posted on 15/12/09 at 05:19 PM |

|

|

hmm, i wouldn't like it, but to be honest, i can't think of a reason why not lol

my head says it would be too wobbly, but all your suspension is bolted on anyway.

i would worry that the 3mm plate would be too bendy though, 5mm would be too heavy

________________________

IVA manual link http://www.businesslink.gov.uk/bdotg/action/detail?type=RESOURCES&itemId=1081997083

don't write OT on a new thread title, you're creating the topic, everything you write is very much ON topic!

|

|

|

rayward

|

| posted on 15/12/09 at 06:02 PM |

|

|

as others have said, can;t see anything wrong with it, but don;t think i;d risk it myself,

my main concern would be the shear effect on the bolts/dowels if the font of the car was hit from the side.

are you using the car for racing ?, if so maybe worth finding a friendly MSA scrutineer, and getting his opinion on it ?

hth

ray

|

|

|

tegwin

|

| posted on 15/12/09 at 06:07 PM |

|

|

In an accident wont the car fail at the weakest point?

Most likely the join between the two chassis parts?

------------------------------------------------------------------------------------------------------------------------

Would the last person who leaves the country please switch off the lights and close the door!

www.verticalhorizonsmedia.tv

|

|

|

sebastiaan

|

| posted on 15/12/09 at 06:08 PM |

|

|

quote:

Originally posted by rayward

my main concern would be the shear effect on the bolts/dowels if the font of the car was hit from the side.

I'd think in a crash you'd want to get rid of as much parts (= kinetic energy!) as you can, so parts flying off would be a bonus?

If you're stood by the side of the track though.... (and that is where the "do not lose wheels in a crash" rule in F1 comes from)

|

|

|

blakep82

|

| posted on 15/12/09 at 06:10 PM |

|

|

^ which would tug on the threads (and would do on heavy bumps, heavy braking etc), rather than through the thickest part of the bolt

quote:

Originally posted by rayward

my main concern would be the shear effect on the bolts/dowels if the font of the car was hit from the side.

if it was hit from the side, its pretty much screwed anyway though

________________________

IVA manual link http://www.businesslink.gov.uk/bdotg/action/detail?type=RESOURCES&itemId=1081997083

don't write OT on a new thread title, you're creating the topic, everything you write is very much ON topic!

|

|

|

smart51

|

| posted on 15/12/09 at 06:13 PM |

|

|

quote:

Originally posted by blakep82

i would worry that the 3mm plate would be too bendy though, 5mm would be too heavy

So you'd go for 4mm then?

|

|

|

blakep82

|

| posted on 15/12/09 at 06:13 PM |

|

|

quote:

Originally posted by smart51

quote:

Originally posted by blakep82

i would worry that the 3mm plate would be too bendy though, 5mm would be too heavy

So you'd go for 4mm then?

that would be too bendy AND heavy

________________________

IVA manual link http://www.businesslink.gov.uk/bdotg/action/detail?type=RESOURCES&itemId=1081997083

don't write OT on a new thread title, you're creating the topic, everything you write is very much ON topic!

|

|

|

rayward

|

| posted on 15/12/09 at 06:15 PM |

|

|

quote:

Originally posted by blakep82

^ which would tug on the threads (and would do on heavy bumps, heavy braking etc), rather than through the thickest part of the bolt

quote:

Originally posted by rayward

my main concern would be the shear effect on the bolts/dowels if the font of the car was hit from the side.

if it was hit from the side, its pretty much screwed anyway though

fair comment, but i think i;d prefer it if the steering stayed as intact as possible right to the end

ray

|

|

|

blakep82

|

| posted on 15/12/09 at 06:18 PM |

|

|

quote:

Originally posted by rayward

quote:

Originally posted by blakep82

^ which would tug on the threads (and would do on heavy bumps, heavy braking etc), rather than through the thickest part of the bolt

quote:

Originally posted by rayward

my main concern would be the shear effect on the bolts/dowels if the font of the car was hit from the side.

if it was hit from the side, its pretty much screwed anyway though

fair comment, but i think i;d prefer it if the steering stayed as intact as possible right to the end

ray

ah, yeah, i was forgetting about what happens til the car comes to rest. you're right, it should really stay on

i was just thinking about what was said about replacing the damaged front. any impact is going to bend the mounting too.

the plates will get twisted, chassis tubes bent, so its never going to be a case of just bolting a new front end on

________________________

IVA manual link http://www.businesslink.gov.uk/bdotg/action/detail?type=RESOURCES&itemId=1081997083

don't write OT on a new thread title, you're creating the topic, everything you write is very much ON topic!

|

|

|

MikeRJ

|

| posted on 15/12/09 at 06:30 PM |

|

|

quote:

Originally posted by blakep82

i would worry that the 3mm plate would be too bendy though, 5mm would be too heavy

3mm plate would certainly be too bendy if it was a couple of large flat plates bolted in the middle. A small bit of 3mm plate supported by box

section around it's periphery would be very rigid.

|

|

|

boggle

|

| posted on 15/12/09 at 07:08 PM |

|

|

you could use 3mm with a triangular press in the middle, or a slight rigid fold throu the center diagonaly...

you need some form of servo saver for the steering? maybe putting the removable section further back?

just because you are a character, doesnt mean you have character....

for all your bespoke parts, ali welding, waterjet, laser, folding, turning, milling, composite work, spraying, anodising and cad drawing....

u2u me for details

|

PLEASE NOTE: This user is a trader who has not signed up for the LocostBuilders registration scheme. If this post is advertising a commercial product or service, please report it by clicking here.

|

MikeRJ

|

| posted on 15/12/09 at 10:18 PM |

|

|

quote:

Originally posted by boggle

you need some form of servo saver for the steering?

It's not a radio controlled car

|

|

|

Volvorsport

|

| posted on 15/12/09 at 11:13 PM |

|

|

hmm , id came up with a design early in my chassis life so that i could convert it to composite chassis later on .

why not use the actual chassis tube section and dowel it tight with some high tensile bolts in the original chassis , you wouldnt need to make the 3mm

mounting plates , and in my opinion not much weight gained and no less stiffness .

www.dbsmotorsport.co.uk

getting dirty under a bus

|

|

|

MK9R

|

| posted on 16/12/09 at 07:19 AM |

|

|

quote:

Originally posted by Volvorsport

hmm , id came up with a design early in my chassis life so that i could convert it to composite chassis later on .

why not use the actual chassis tube section and dowel it tight with some high tensile bolts in the original chassis , you wouldnt need to make the 3mm

mounting plates , and in my opinion not much weight gained and no less stiffness .

mmmm, interesting idea. When a chassis gets cut and shut it uses that principle, but obviously welded rather than bolted.

Cheers Austen

RGB car number 9

www.austengreenway.co.uk

www.automatedtechnologygroup.co.uk

www.trackace.co.uk

|

|

|

Guihanos

|

| posted on 16/12/09 at 09:28 AM |

|

|

Does you modeling software has something like Cosmos in Solidworks? It could give you an idea of which aera will have the highest stress.

|

|

|

MK9R

|

| posted on 16/12/09 at 09:31 AM |

|

|

quote:

Originally posted by Guihanos

Does you modeling software has something like Cosmos in Solidworks? It could give you an idea of which aera will have the highest stress.

No, its actually a CAD package for simulating robotic automation, bt has a simple modelling tool that i can knock stuff up in very quickily. It has

Kinematics, but not stress evaluation

Cheers Austen

RGB car number 9

www.austengreenway.co.uk

www.automatedtechnologygroup.co.uk

www.trackace.co.uk

|

|

|

se7en

|

| posted on 31/12/09 at 07:01 PM |

|

|

I have seen it done on F2 stock cars away back in the 80's. There is nothing new about this chassis.

IICR Audi did something similar with the Le Mans cars when the rear suspension/drive train was held on to the car by 4 bolts.

The only thing to keep in mind is a chassis is only as strong as it's weakest point.

|

|

|