matt.c

|

posted on 11/4/08 at 08:02 PM posted on 11/4/08 at 08:02 PM |

|

|

INDY GEAR CHANGE RODS

Hi locosters, Im having a bit of trouble at the moment with the sloppyness of my gear changing rods. I have the rod ends as close to the pivots but

there is still to much movement for me.

I like the feel of the gearknob being very solid ie less movement for gear changing.

What about moving the rod from the bottom of the gear stick to the middle or as high as i can get to the gear knob. Will this minimalise the

movement?

Gear

|

|

|

|

|

jacko

|

| posted on 11/4/08 at 08:08 PM |

|

|

Road runner has some photos in his archives how he made his it may help you

Jacko

|

|

|

dan__wright

|

| posted on 11/4/08 at 08:08 PM |

|

|

no that would make it further, move it further from the pivot, or change it the gaerbox engine put it closer to the selector.

FREE THE ROADSTER ONE…!!

|

|

|

mackei23b

|

| posted on 11/4/08 at 08:16 PM |

|

|

Hi Matt

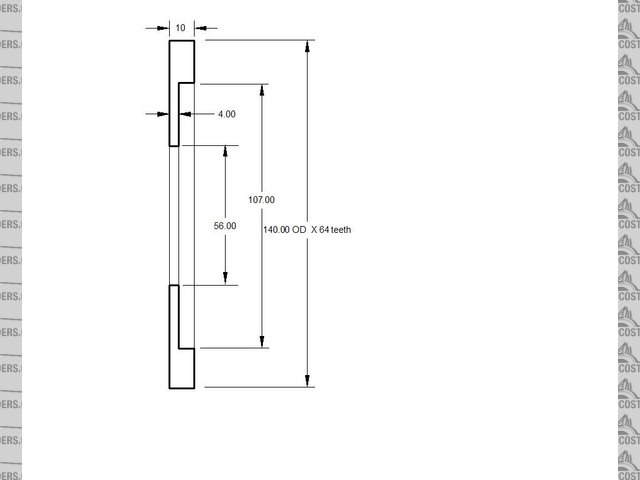

Here are your options for less movement at the gear lever:

Option 1 lengthen point A from pivot

Option 2 shorten point B from pivot

Option 3 lengthen point C from pivot

Option 4 shorten point D towards pivot

Cheers

Ian

[Edited on 11/4/08 by mackei23b]

[Edited on 11/4/08 by mackei23b]

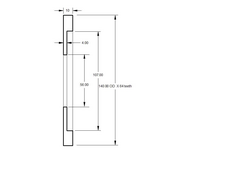

Rescued attachment Gear Link.JPG

|

|

|

matt.c

|

| posted on 11/4/08 at 08:33 PM |

|

|

Have made all the rods as close as possible to there pivots. If thats the case then would pic 2 have less movement at the gearknob than pic 1?

I could make the link fit higher on the gearknob.

[Edited on 11/4/08 by matt.c]

|

|

|

mackei23b

|

| posted on 11/4/08 at 09:04 PM |

|

|

Yes it would.

quote:

Originally posted by matt.c

Have made all the rods as close as possible to there pivots. If thats the case then would pic 2 have less movement at the gearknob than pic 1?

I could make the link fit higher on the gearknob.

[Edited on 11/4/08 by matt.c]

|

|

|

gingerprince

|

| posted on 13/4/08 at 05:53 PM |

|

|

quote:

Originally posted by matt.c

Have made all the rods as close as possible to there pivots. If thats the case then would pic 2 have less movement at the gearknob than pic 1?

I could make the link fit higher on the gearknob.

[Edited on 11/4/08 by matt.c]

If all your joints are as close to the pivots as possible, then the easiest way is probably to drill point C in mackei's diagram further out -

that'll increase throw to the engine compared to throw in your hand achieving what you want. I wouldn't bother re-engineering the whole

thing like you were suggesting.

|

|

|