theprisioner

|

| posted on 13/7/12 at 06:08 PM |

|

|

Swirl pot question

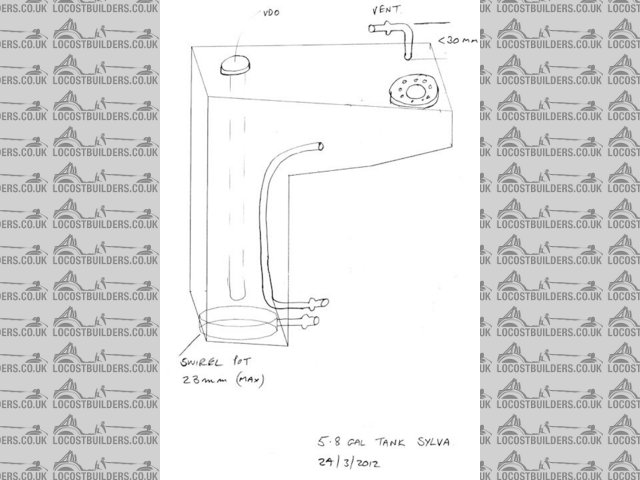

Sylva special tank

I have a swirel pot, but not enough head to gravity feed a Bosch type 044 pump.

All the recommendations are that the 044 must be gravity fed with a minimal head.

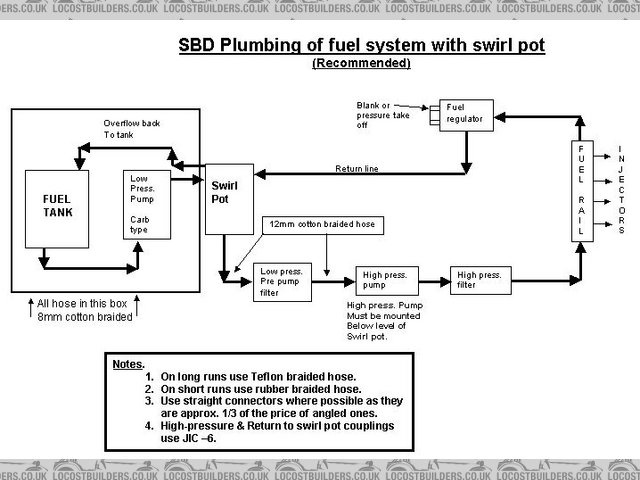

So I have been following the SBD advice about going down the external swirel pot route:

SBD recommends

I have done some experiments with a solid state pump and I can easily solve the head problem.

Question: As I have a swirel pot can I just leave out the external one and put both pumps in series?

P.S. I don't want to go the in tank pump route.

|

|

|

|

|

paulf

|

| posted on 13/7/12 at 08:14 PM |

|

|

I dont think it would be a good idea as the flow rate of the LP pump would most likely be less than the HP and restrict the flow and would therefore

achieve nothing.

Why do you think the feed from the in tank swirl pot would not be enough? most people fit a swirl pot and then fit the HP pump level with the base of

it so the only head is the depth of the swirl pot.

Paul

|

|

|

tomgregory2000

|

| posted on 13/7/12 at 08:57 PM |

|

|

quote:

Originally posted by paulf

so the only head is the depth of the swirl pot.

Paul

And all the fuel above that

|

|

|

theprisioner

|

| posted on 13/7/12 at 10:11 PM |

|

|

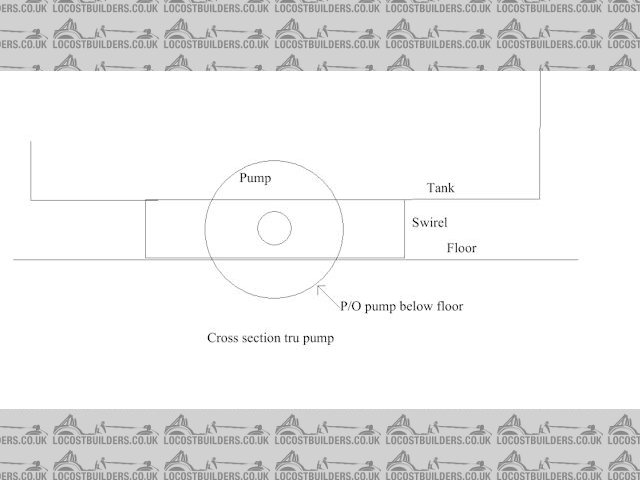

Pump below floor

My understanding is part of the HP pump in my case would be below floor level to gain head when the fuel is level with the top of the swirel?

Pump issue

|

|

|

britishtrident

|

| posted on 14/7/12 at 05:31 AM |

|

|

You are adding too much complication -- keep things simple.

if the tank shape is as shown in the sketch you don't need anything other than the HP pump mounted with the pump inlet level (or below )

the bottom of the tank. You don't even need the baffle (what you call a swirl pot) in the bottom of the tank.

[I] “ What use our work, Bennet, if we cannot care for those we love? .”

― From BBC TV/Amazon's Ripper Street.

[/I]

|

|

|

adithorp

|

| posted on 14/7/12 at 07:47 AM |

|

|

quote:

Originally posted by britishtrident

You are adding too much complication -- keep things simple.

if the tank shape is as shown in the sketch you don't need anything other than the HP pump mounted with the pump inlet level (or below )

the bottom of the tank. You don't even need the baffle (what you call a swirl pot) in the bottom of the tank.

What he said... KISS!

HP pumps don't like to pull/suck and can cause cavitation in the fuel lines but with the pump level with the outlet from your tank you'll

have no problem. Mine was level with the top of the tank for 1 1/2 years (5000miles) with no running problems. Then moved level with the outlet where

it''s been fine for 2 1/2 years.

"A witty saying proves nothing" Voltaire

http://jpsc.org.uk/forum/

|

|

|

theprisioner

|

| posted on 14/7/12 at 08:29 AM |

|

|

Thanks

I do have a habit of over complicating designs, that is why I posted this discussion in the first place, so I am grateful for the responses. That is

why I find this forum so valuable.

Part of my question was prompted by the leaflet in the Sytec box:

" FUEL PUMPS ARE LUBRICATED & COOLED BY THE FUEL - DO NOT ALLOW THE FUEL LEVEL TO RUN EXCESSIVELY LOW"

"INJECTION PUMPS MUST BE GRAVITY FED (OR BY A LIFT PUMP)"

I assumed (possibly wrongly) a solid state pump could be regarded as a lift pump?

Note no reference to a swirel pot in between?

Anyway thanks for the responses I am listening!

|

|

|

britishtrident

|

| posted on 14/7/12 at 01:22 PM |

|

|

Tank -> hp pump - > hp filter -> regulator (with return) - > injectors = job done.

It is no different from a Bosch HP pump fitted in tank the fuel in the tank gives you a positive head of pressure at the hp pump inlet.

[I] “ What use our work, Bennet, if we cannot care for those we love? .”

― From BBC TV/Amazon's Ripper Street.

[/I]

|

|

|

tomgregory2000

|

| posted on 14/7/12 at 08:04 PM |

|

|

quote:

Originally posted by britishtrident

Tank -> hp pump - > hp filter -> regulator (with return) - > injectors = job done.

It is no different from a Bosch HP pump fitted in tank the fuel in the tank gives you a positive head of pressure at the hp pump inlet.

The regulator comes after the injectors in a normal set up

|

|

|

owelly

|

| posted on 14/7/12 at 08:30 PM |

|

|

It matters not where the regulator comes off as long as it holds the correct pressure in the fuel rail. I had mine mounted on the return at the tank

for a few weeks during some under-bonnet tweaking and it was fine.

http://www.ppcmag.co.uk

|

|

|