DarrenW

|

| posted on 30/1/06 at 03:04 PM |

|

|

Can anyone explain diffs??

Im trying to understand diffs.

1. First conundrum is what do i have (tag was snapped off). I think i have sussed this out now as a 3.62:1. Speedo was calibrated at SVA (DD2). I

worked backwards thro ETB calculator and the only std ratio that fits the formula is the 3.62. This puzzled me as donor was manual gearbox 1992 2.0i

DOHC Sierra which my research says should be 3.92.

2. 2nd conundrum is to get it in my head what happens if i change diffs. For example ive been playing with 0-60 timer. I have to drop it into 3rd to

reach 60. Ive then sussed changing to 3.38 diff will reach 60 in 2nd and save me a gear change. I then could see that a 3.38 diff will give me a

higher top end - does this therefore follow that acceleration will suffer and as such a change may not improve 0-60 time???

Could i actually gain some acceleration going for a 3.92 or higher diff by sacrificing some top end.

3. Later step maybe to determine where the diffs come from and if pinion / crownwheel sets can be bought. How do people get 4.1:1 etc for their race

cars?? i assume these high geared diffs are to give good acceleration on tracks that are too short to get high top end speeds.

This is all theorising at the moment. I wont make any changes till i get some track time in and perfect the engine / suspension set up. Ive got some

bhp to find yet.

|

|

|

|

|

stevebubs

|

| posted on 30/1/06 at 03:08 PM |

|

|

1. This is only a rule of thumb really - Ford sometimes fitted whatever they felt like, and who says the diff is original anyhow?

2. Yes.

3a. Transmission specialists, e.g. Quaife and others will supply CWP sets...

3b. Yes

[Edited on 30/1/06 by stevebubs]

|

|

|

smart51

|

| posted on 30/1/06 at 03:22 PM |

|

|

the best way to check what ratio diff you have is to count the number of turns if the input shaft are needed to turn the outputs by 1 rev. For a

sierra diff it will be 3.92, 3.62, 3.38 or 3.14.

A higher numbered diff will give you lower gearing. That is you will have more acceleration in each gear but the top speed in that gear will be less.

To work out how much, divide the old diff ratio by the new one. overall the acceleration of your car will be the same, however over ceartain

measured distances or speeds, one diff may seem better than another.

if a 0-60 time is what you want then gear the car to reach 63 or 65 MPH in 2nd at the red line. Be sure that your engine is up to this job though.

some small engined cars are geared for this speed but bog down the engine when shifting to 2nd as the engine doesn't have enough grunt.

I would suggest that it is better to choose a diff for drivability more than anything else. If 3rd gear only takes you to 69 MPH then you will over

rev it when accelerating up a motorway slip road, far example.

As for changing crown wheels and pinions, leave it. You cna change the gearing by fitting different sized road wheels and tyres as well, you know.

|

|

|

DarrenW

|

| posted on 30/1/06 at 04:01 PM |

|

|

this is an interesting link on the subject.

http://forum.fordsierraclub.co.uk/viewtopic.php?t=5843

Im currently running 15" wheels with 195/50 tyres. If i drop down to 13" wheels with 185/60's (5% drop in circumference) would this

effectively give better acceleration but slightly lower speed in each gear?

|

|

|

smart51

|

| posted on 30/1/06 at 04:10 PM |

|

|

yes, bit it is rolling circumference, not unladen that matters. Don't go multiplying the nominal width by the nominal aspect ratio. It

doesn't really work like that.

a 195/50/15 wheel and tyre has a rolling circumference of 1760mm when inflated to the correct pressure and has no tread wear.

|

|

|

DarrenW

|

| posted on 30/1/06 at 04:20 PM |

|

|

Im please you posted 1760mm. Ive just had a piece of string around my wheel and measured 1750mm. i know it was a touch short cos concrete floor was in

the way of being more accurate.

When ive been doing some calcs to see effect diffs have on road speed i used 1750mm so at least i got that bit right.

Sounds to me that it would be better to get to 60 comfortably in third knowing that the car is accellerating strongly right through. To be honest i

can gain huge improvements in acceleration by;

1. Waiting till summer when i have a hope of getting traction,

2. Fianalising basic set up and releasing those horses (well, maybe ponies!),

3. practising launch technique,

4. Continue with eating these salads to shed some more pounds. I can gain approx 8bhp/tonne by losing 20Kg weight!!! How much would that cost to gain

in £££'s???

All good stuff though so keep the advice rolling.

|

|

|

britishtrident

|

| posted on 30/1/06 at 05:07 PM |

|

|

Feed the numbers in to work out what happens to your acceleration figures if you ignore 1st gear and start in 2nd using a low diff ratio.

Actual tyre manufacturers figures for 195/50x15 show has a equivalent rolling circumfrence of 1809mm -- although the tyre compresses a tiny

bit at the bottom due to weight it grows in radius once under way due centrafugal forces and tyre wall reactions. Also section size dosen't

allow for tread depth.

If you actually do the maths on the section size aspect ration and diameter it actually works out pretty close to 1809mm

[Edited on 30/1/06 by britishtrident]

|

|

|

Triton

|

| posted on 30/1/06 at 07:21 PM |

|

|

Nope seriously strange things diffs....made to blow yer mind as well as provide drive

My Daughter has taken over production of the damn fine Triton race seats and her contact email is emmatrs@live.co.uk.

www.tritonraceseats.com

www.hairyhedgehog.com

|

|

|

smart51

|

| posted on 30/1/06 at 07:31 PM |

|

|

quote:

Originally posted by britishtrident

Actual tyre manufacturers figures for 195/50x15 show has a equivalent rolling circumfrence of 1809mm

Funny that, that's where I got 1760 from. I also measured two rolled circumferences from the 195/50/15s on my road car just to check and that

came out at 1760mm x 2. Which brand of tyre did you get your data from?

I've just done a google search on 1760 (OK no not guarraneed to be accurate) but alfa / opel / renault / smart owners websites quote 1760mm for

195 50 15s. OK, there's less than 3% in it so you'll hardly notice.

[Edited on 30-1-2006 by smart51]

|

|

|

iank

|

| posted on 30/1/06 at 07:45 PM |

|

|

Using http://www.miata.net/garage/tirecalc.html

and plugging in 195/50-15

gives:

Specification Sidewall Radius Diameter Circumference Revs/km

195/50-15 98mm 288mm 576mm 1810mm 553

(sorry about the formatting).

But unless the tyre's steel bands allow stretching or the tyre is moving on the rim I don't see how the inflation/tyre rpm will affect

anything except the shape - the tread circumference should remain the same, so the revs per mile should be constant.

|

|

|

bimbleuk

|

| posted on 31/1/06 at 10:13 AM |

|

|

Search for GearCalc as this is very useful for calculating your diff and GBX ratios.

On my Striker I decided on a 4.4:1 diff with a BGH 5 speed box. The BGH box is built with much taller 1st and 2nd gears to offset the much shorter

diff ratio. Also effectively makes it a close ration GBX.

I run on 14" alloys with 185x60 tyres. On the road I can get to 60mph in 2nd but I have to use the full rev range on my 20V 4AGE i.e.

8000RPM!

Top speed is approx 125mph but it does get there v. v. quickly. Both the diff and GBX have been built to take the abuse but are very expensive

compared to using standard parts

70mph is around 4500rpm which might be high for a lot of peeps but I mostly travel to work (18 miles) or to trackdays so I get the maximum benefit on

track.

|

|

|

smart51

|

| posted on 31/1/06 at 10:41 AM |

|

|

quote:

Originally posted by iank

...unless the tyre's steel bands allow stretching or the tyre is moving on the rim I don't see how the inflation/tyre rpm will affect

anything except the shape - the tread circumference should remain the same, so the revs per mile should be constant.

The weight of your car will push the tyre out of round where it touches the floor. the radius of the wheel from the (static laden radius) will be

less than the free radius. This does affect the rolling circumference.

195mm x 50% x 2 + 15" x 25.4mm x PI = 1809.6mm This is the theoretical circumference. A simple calculator of tyre size from the numbers will

give you this. The rolling curcumference will be less.

|

|

|

iank

|

| posted on 31/1/06 at 11:30 AM |

|

|

quote:

Originally posted by smart51

quote:

Originally posted by iank

...unless the tyre's steel bands allow stretching or the tyre is moving on the rim I don't see how the inflation/tyre rpm will affect

anything except the shape - the tread circumference should remain the same, so the revs per mile should be constant.

The weight of your car will push the tyre out of round where it touches the floor. the radius of the wheel from the (static laden radius) will be

less than the free radius. This does affect the rolling circumference.

195mm x 50% x 2 + 15" x 25.4mm x PI = 1809.6mm This is the theoretical circumference. A simple calculator of tyre size from the numbers will

give you this. The rolling curcumference will be less.

Hmm we might be talking about different things, but the total length of the tread will be constant (I don't believe they stretch since they are

full of steel bands), and the trigonometric circumference is as good a guess as any for that.

For each rotation of the wheel all of that tread will touch the road, so it shouldn't matter what the radius from the middle of the wheel to the

road is at any point in time. For each wheel revolution the car should move forward by the length of the tread.

|

|

|

britishtrident

|

| posted on 31/1/06 at 11:46 AM |

|

|

The total perimeter of the tread dosen't increase but the radius at the contact patch "plumps up" --- anyone who has experience a

tyre deflate at motorway speeds but stay on the rim will know the tyre to a very large extent stays "up" until the speed falls below about

30mph.

|

|

|

smart51

|

| posted on 31/1/06 at 11:52 AM |

|

|

You both seem to be using the "surely it doesn't" arguement. I have read in various sources that "in fact it does".

The difference in any case is small. The michelin tyre size guide that I seem to have lost certainly states a rolling circumference for each of its

tyres that is less than the theoretical radius. I'll see if I can dig it out.

|

|

|

iank

|

| posted on 31/1/06 at 12:00 PM |

|

|

Actually using the logic/maths shows that the tread patch shape doesn't matter to the distance per rev assuming the tread doesn't

stretch/contract. (as an aside surely sidewalls would split if that happened).

So does the tread length change, or do some manufacturers play silly games with their specifications for some reason - which is perhaps the most

likely situation

|

|

|

Schrodinger

|

| posted on 31/1/06 at 01:04 PM |

|

|

The tyre walls destort as does the tread giving a smaller rolling circumference, just look at your tyres as the car stands on the road, the walls

bulge allowing the tread to be closer to the centre of the wheel.

regards

Keith

Suffolk

|

|

|

iank

|

| posted on 31/1/06 at 01:19 PM |

|

|

quote:

Originally posted by Schrodinger

The tyre walls destort as does the tread giving a smaller rolling circumference, just look at your tyres as the car stands on the road, the walls

bulge allowing the tread to be closer to the centre of the wheel.

regards

Keith

Suffolk

Yes the distortion is obvious. However I don't believe it the tread grows longer because of it, so the distance per rev remains the same.

Look at the construction of a radial tyre, there are steel belts running under the tread, so I don't think it's able to stretch a

significant amount.

http://en.wikipedia.org/wiki/Radial_tire

|

|

|

britishtrident

|

| posted on 31/1/06 at 01:39 PM |

|

|

A couple of points

Tyre section size is the carcase section size --- the tread is on top of this.

Tyres change shape with rotational speed -- try jacking a driven wheel up and put the car in a high gear with the engine running just watch the

shape of tyre change.

|

|

|

iank

|

| posted on 31/1/06 at 02:00 PM |

|

|

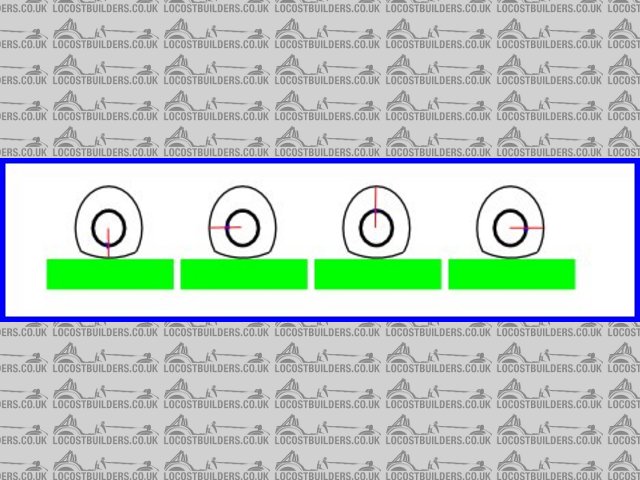

Time for a badly drawn diagram

tyre distortion

Wheel rotating clockwise with a really heavy load on it making the bottom distort. The red line shows the radius of a particular point on the tyre,

changing depending on where it is. If the tyre doesn't slip on the rim. the point where the red line crosses the rim and meets the tread will

be the same in relation to one another.

Clear as mud  But I think this shows the distortion of the contact patch doesn't make any difference to the distance per rev. But I think this shows the distortion of the contact patch doesn't make any difference to the distance per rev.

Now the question comes back to am I right that the tread doesn't stretch significantly because the metal belts hold it in position - is this not

the main function of the belts? i.e. to keep it from getting bigger (and exploding at high speed) due to the centripetal forces from the rotation.

If I'm not right I'd appreciate a reference or a clear explanation so I can learn for the future.

|

|

|

MikeRJ

|

| posted on 31/1/06 at 02:34 PM |

|

|

The effective rolling radius of a tyre IS slightly less than the measured unladen radius. The carcass of the tyre cannot stretch or compress due to

the steel belts, but over the length of the contact patch, the tyres tread does compress slightly, reducing the effective circumference of the tyre.

IIRC the difference is only of the order of 2% for modern radial tyres. I guess this implies that a worn tyre will have a smaller effective change in

RR from laden to unladed as the tread will be that much closer to the belts, and hence less able to compress.

2% is probably smaller than the RR change from a new tyre to a worn one, so it's not really that critical in the grand scheme of things.

|

|

|

iank

|

| posted on 31/1/06 at 02:42 PM |

|

|

quote:

Originally posted by MikeRJ

The effective rolling radius of a tyre IS slightly less than the measured unladen radius. The carcass of the tyre cannot stretch or compress due to

the steel belts, but over the length of the contact patch, the tyres tread does compress slightly, reducing the effective circumference of the tyre.

IIRC the difference is only of the order of 2% for modern radial tyres. I guess this implies that a worn tyre will have a smaller effective change in

RR from laden to unladed as the tread will be that much closer to the belts, and hence less able to compress.

2% is probably smaller than the RR change from a new tyre to a worn one, so it's not really that critical in the grand scheme of things.

Excellent, now I understand. Thanks.

|

|

|

Liam

|

| posted on 31/1/06 at 04:32 PM |

|

|

Wanna see tyres expanding with speed? Check out a top fuel dragster burnout! Probably a good 20-30% increase in diameter. In fact it's well

documented that during the run, the expansion of the tyre with speed acts just like a CVT changing the dragsters gearing. God knows what sort of tyre

construction they use though.

liam

|

|

|

iank

|

| posted on 31/1/06 at 04:39 PM |

|

|

quote:

Originally posted by Liam

Wanna see tyres expanding with speed? Check out a top fuel dragster burnout! Probably a good 20-30% increase in diameter. In fact it's well

documented that during the run, the expansion of the tyre with speed acts just like a CVT changing the dragsters gearing. God knows what sort of tyre

construction they use though.

liam

The top fuel dragsters don't use Steel banded Radials  Still on crossplys I think, though Hooisier call them 'bias' tires. Still on crossplys I think, though Hooisier call them 'bias' tires.

[Edited on 31/1/06 by iank]

|

|

|

Stu16v

|

| posted on 31/1/06 at 06:10 PM |

|

|

'Bias', or bias belted, are a different tyre type again to crossplys and radials...

Dont just build it.....make it!

|

|

|