chrisg

|

| posted on 8/2/08 at 04:47 PM |

|

|

Spring steel

Just a quick question, does spring steel lose it's temper if you weld it?

I don't mean does it get upset so all you smart arses can step away from the keyboard!!!

Does it affect the spring properties?

Cheers

Chris

Note to all: I really don't know when to leave well alone. I tried to get clever with the mods, then when they gave me a lifeline to see the

error of my ways, I tried to incite more trouble via u2u. So now I'm banned, never to return again. They should have done it years ago!

|

|

|

|

|

02GF74

|

| posted on 8/2/08 at 04:49 PM |

|

|

if you weld it in summer you'll be fine.

|

|

|

Mr Whippy

|

| posted on 8/2/08 at 04:52 PM |

|

|

quote:

Originally posted by 02GF74

if you weld it in summer you'll be fine.

groan groan

to answer your question, yes it becomes soft and losses it springyness, is that a word?

[Edited on 8/2/08 by Mr Whippy]

|

|

|

02GF74

|

| posted on 8/2/08 at 04:54 PM |

|

|

spring steel is heat treated and this treatment varies depending on the application it is put to use.

So if you heat it up, then you will affect its properties in some way.

you can retemper it ofcourse but will it be the same as the original? I cannot say.

Best not to in my opinion.

|

|

|

britishtrident

|

| posted on 8/2/08 at 05:02 PM |

|

|

Spring steels vary from 0.5% (leaf spring) to 1.0% carbon by the text book any steel over 0.4% carbon after hot work should be re-heated water

quenched and then re heated again to a lower temperature and tempered by slow cooling.

I have seen springs sucessfully cut down using a gas axe without re-heatreating but never welded.

In any case even on to a spring is trick -- what are you trying to do ?

|

|

|

britishtrident

|

| posted on 8/2/08 at 05:11 PM |

|

|

quote:

Originally posted by Mr Whippy

quote:

Originally posted by 02GF74

if you weld it in summer you'll be fine.

groan groan

to answer your question, yes it becomes soft and losses it springyness, is that a word?

[Edited on 8/2/08 by Mr Whippy]

Welding is most likely to produce a localised HAZ area which is excessively hard ie brittle with other adjacent area further from the weld which are

ductile (soft).

The value of "E" "springyness" for steel is more or less unaffected by heat treatment/hot work the elastic limit however

will be changed.

[Edited on 8/2/08 by britishtrident]

[I] “ What use our work, Bennet, if we cannot care for those we love? .”

― From BBC TV/Amazon's Ripper Street.

[/I]

|

|

|

chrisg

|

| posted on 8/2/08 at 05:12 PM |

|

|

it's for an "blade" type adjustable anti-roll bar. I can make up a bolted fixing but it would be much easier to weld it.

Do you think it could be welded and re tempered then BT?

cheers

Chris

Note to all: I really don't know when to leave well alone. I tried to get clever with the mods, then when they gave me a lifeline to see the

error of my ways, I tried to incite more trouble via u2u. So now I'm banned, never to return again. They should have done it years ago!

|

|

|

britishtrident

|

| posted on 8/2/08 at 05:18 PM |

|

|

quote:

Originally posted by chrisg

it's for an "blade" type adjustable anti-roll bar. I can make up a bolted fixing but it would be much easier to weld it.

Do you think it could be welded and re tempered then BT?

cheers

Chris

It could be quenched then re heated tempered but I would be tempted to try brazing or silver soldering the fitting it on as the tempereatures

involved are lower.

One problem with any kind of torsion bar is you have to avoid stress raiser and changes of section as much as possible.

Most anti-roll bars can be made of mild steel without problem.

[I] “ What use our work, Bennet, if we cannot care for those we love? .”

― From BBC TV/Amazon's Ripper Street.

[/I]

|

|

|

chrisg

|

| posted on 8/2/08 at 05:27 PM |

|

|

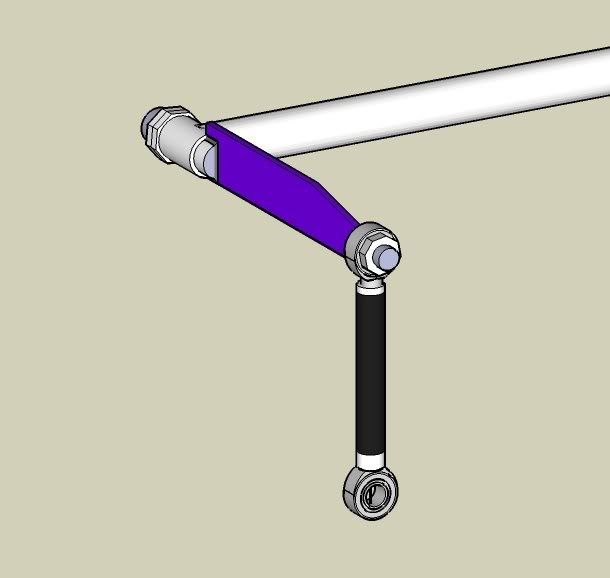

This is the set-up I'm looking for, the spring steel acts like a solid bar when it's orientated as shown in the picture, but it can be

rotated anywhere up to 90 degrees to reduce the effectiveness of the ARB.

Brazing is an option I might look into, it might by tripe but silver soldering never looks strong enough to me!

Cheers

Chris

Note to all: I really don't know when to leave well alone. I tried to get clever with the mods, then when they gave me a lifeline to see the

error of my ways, I tried to incite more trouble via u2u. So now I'm banned, never to return again. They should have done it years ago!

|

|

|

bonzoronnie

|

| posted on 8/2/08 at 06:57 PM |

|

|

Pre heating of the anti roll bar prior to welding may be of some use.

Ronnie

|

|

|

NS Dev

|

| posted on 8/2/08 at 11:21 PM |

|

|

in simple terms, no you cant' weld it.

sorry

I have done it once, and only once. it broke and the car ended up in the gravel trap.

Retro RWD is the way forward...........automotive fabrication, car restoration, sheetmetal work, engine conversion

retro car restoration and tuning

|

|

|