stuleah

|

| posted on 1/3/10 at 08:14 PM |

|

|

how have you fitted your pedalbox?

as title, i have a floor mounted pedal box and was wandering how the best way of fitting it is? pictures would good if poss.

|

|

|

|

|

big-vee-twin

|

| posted on 1/3/10 at 08:27 PM |

|

|

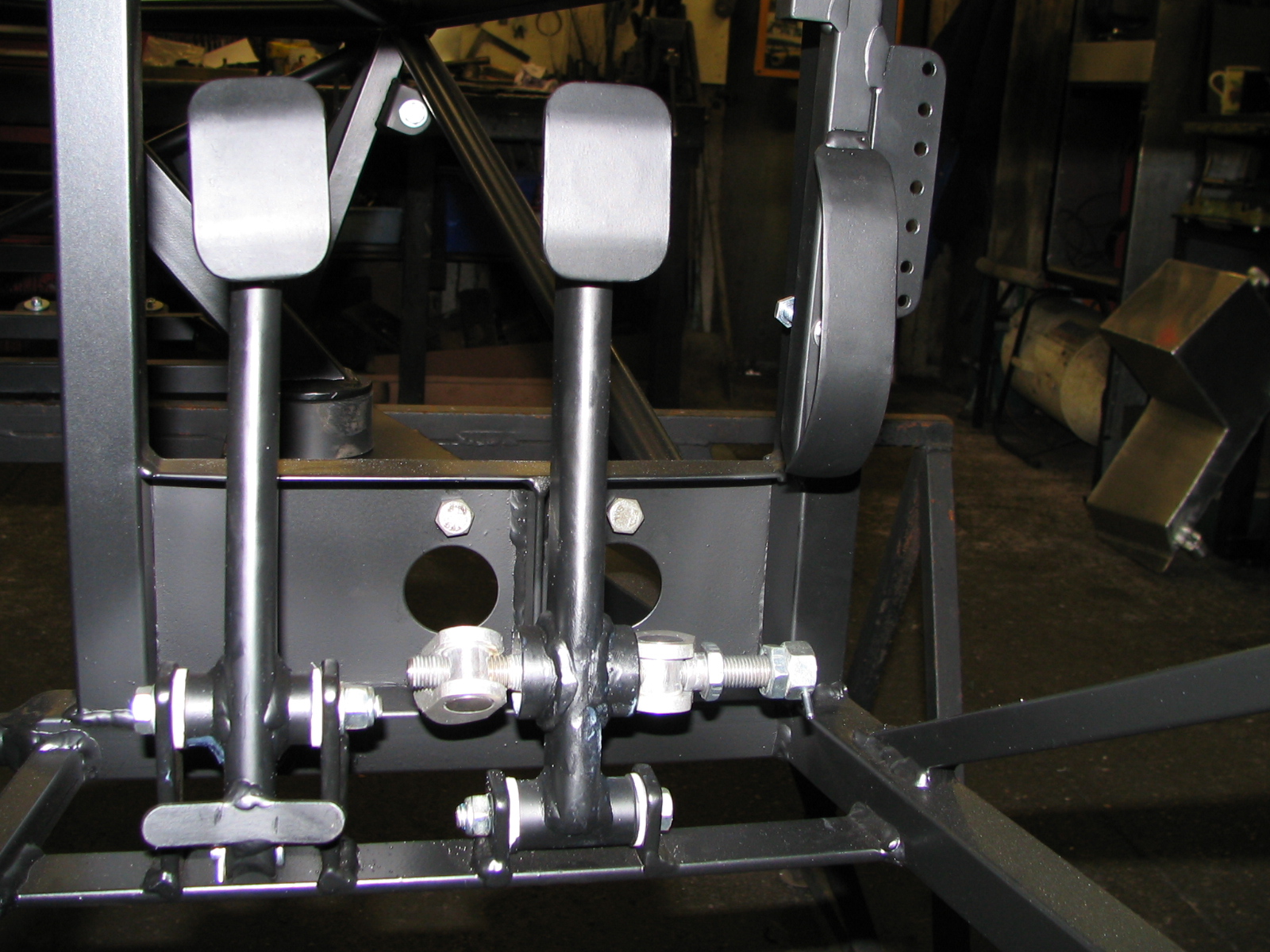

.jpg)

.jpg)

[Edited on 1/3/10 by big-vee-twin]

Duratec Engine is fitted, MS2 Extra V3 is assembled and tested, engine running, car now built. IVA passed 26/02/2016

http://www.triangleltd.com

|

|

|

stuleah

|

| posted on 1/3/10 at 08:44 PM |

|

|

thanks for the reply, are the 6 bolts for the m/cylinders the main thing that holds it in place?

|

|

|

boggle

|

| posted on 1/3/10 at 08:46 PM |

|

|

will let you know after the week end.....

im making it over the next few days....

just because you are a character, doesnt mean you have character....

for all your bespoke parts, ali welding, waterjet, laser, folding, turning, milling, composite work, spraying, anodising and cad drawing....

u2u me for details

|

PLEASE NOTE: This user is a trader who has not signed up for the LocostBuilders registration scheme. If this post is advertising a commercial product or service, please report it by clicking here.

|

stuleah

|

| posted on 1/3/10 at 08:54 PM |

|

|

cool keep us posted.

|

|

|

hicost blade

|

| posted on 1/3/10 at 08:55 PM |

|

|

I made mine by giving my car to Pro Comp and then handing them some money.....

I'm also a dab hand at making curry, using a phone and £20

If you want a decent pedal box you can't beat 20 years of development

|

|

|

stuleah

|

| posted on 1/3/10 at 08:59 PM |

|

|

LOL

|

|

|

boggle

|

| posted on 1/3/10 at 09:18 PM |

|

|

quote:

Originally posted by hicost blade

I made mine by giving my car to Pro Comp and then handing them some money.....

I'm also a dab hand at making curry, using a phone and £20

If you want a decent pedal box you can't beat 20 years of development

thought it was about keeping it locost???

and 20 years ago they had to start somewhere???

just because you are a character, doesnt mean you have character....

for all your bespoke parts, ali welding, waterjet, laser, folding, turning, milling, composite work, spraying, anodising and cad drawing....

u2u me for details

|

PLEASE NOTE: This user is a trader who has not signed up for the LocostBuilders registration scheme. If this post is advertising a commercial product or service, please report it by clicking here.

|

hicost blade

|

| posted on 1/3/10 at 09:30 PM |

|

|

quote:

thought it was about keeping it locost???

and 20 years ago they had to start somewhere???

Some things are worth splashing out on, safety critical items being top of my list.....

And development.......I don't think it's worth explaining, you either want or you don't....I did

BTW my car is being built as a track car I can use and abuse....

[Edited on 1/3/10 by hicost blade]

|

|

|

boggle

|

| posted on 1/3/10 at 09:35 PM |

|

|

its only unsafe if you dont know or unsure what you are doing....if that s the case then fair play....

you could say the same with the steering components etc.....i just dont see the point in parting with your hard earned if you have the knowledge and

facilities to do it yourself.......

just because you are a character, doesnt mean you have character....

for all your bespoke parts, ali welding, waterjet, laser, folding, turning, milling, composite work, spraying, anodising and cad drawing....

u2u me for details

|

PLEASE NOTE: This user is a trader who has not signed up for the LocostBuilders registration scheme. If this post is advertising a commercial product or service, please report it by clicking here.

|

boggle

|

| posted on 1/3/10 at 09:57 PM |

|

|

interesting that yours is intergrated as part of the chassis, and the design is simplistic and minimalistic......

nothing difficult there......

just because you are a character, doesnt mean you have character....

for all your bespoke parts, ali welding, waterjet, laser, folding, turning, milling, composite work, spraying, anodising and cad drawing....

u2u me for details

|

PLEASE NOTE: This user is a trader who has not signed up for the LocostBuilders registration scheme. If this post is advertising a commercial product or service, please report it by clicking here.

|

big-vee-twin

|

| posted on 1/3/10 at 10:44 PM |

|

|

6 bolts through bulkhead and 2 x 8mm botls through floor pan with large washers to spread load

Duratec Engine is fitted, MS2 Extra V3 is assembled and tested, engine running, car now built. IVA passed 26/02/2016

http://www.triangleltd.com

|

|

|

hicost blade

|

| posted on 1/3/10 at 11:39 PM |

|

|

quote:

Originally posted by boggle

interesting that yours is intergrated as part of the chassis, and the design is simplistic and minimalistic......

nothing difficult there......

You could say that about anything.......there are loads of factors, making it look simple is part of the process

You need to look at ratio, stiffness, pedal feel, position, weight, strength, adjustability....you pay the money because they have done all the hard

work

It's not just a question of; if it looks right it is right

As I say mine is being built for the track, I don't really want a 'compromise'

[Edited on 1/3/10 by hicost blade]

|

|

|

stuleah

|

| posted on 2/3/10 at 07:28 AM |

|

|

thanks big vee thats given me some idea,

my only problem is the bulk head is further away than that so i will have to bolt it through the floor with half a dozen bolts.

|

|

|

alistairolsen

|

| posted on 2/3/10 at 08:06 AM |

|

|

All pedal boxes are a compromise anyway unless designed for a specific set of calipers and master cylinders!

The procomp one looks nice, I like the use of oval tube on the pedals. I dont like the way they mount on the tops of the crossmember, I'd have

done them on the front unless youre really tall.

My Build Thread

|

|

|

hicost blade

|

| posted on 2/3/10 at 01:29 PM |

|

|

My box was bespoke and built to the specification (http://en.wikipedia.org/wiki/Specification_(technical_standard)) of my car and components

including master cylinder size and brake caliper piston size, the clutch ratio was developed through experience as was the accelerator ratio.

The picture is not of my car...

and yes I am tall and my car is 4" shorter than a Locost.

I'm just trying to give stuleah information about MY car......

|

|

|

SPYDER

|

| posted on 2/3/10 at 04:16 PM |

|

|

quote:

Originally posted by boggle

i just dont see the point in parting with your hard earned if you have the knowledge and facilities to do it yourself.......

Me neither. Here's our effort, knocked up at work during lunch hours/ nightshifts.

It's locost too! We only paid for the balance bar and master cylinders.

Stuleah, try to bolt your pedal box to the floor as well as the bulkhead. Depending on what stage of chassis build you are at you may wish to weld

tabs or gussets into the chassis to bolt through as drilling through the chassis rails can be a no-no.

Or introduce an extra rail just to bolt to.

Our pedal mounts are integrated into the chassis.

Despite our bulkhead being strengthened between the master cylinders we still found the area would flex when the brakes were applied, so extra gussets

were fitted. Such flexing is to be avoided at all costs.

Geoff.

[img] [/img] [/img]

[Edited on 2/3/10 by SPYDER]

[Edited on 2/3/10 by SPYDER]

|

|

|