jonti

|

| posted on 21/3/04 at 06:30 PM |

|

|

Round Speedo for a Fiver

Some of you high tech types may scoff at this as a bodge and my apologies if it's old stuff that I've only just stumbled upon.

Anyway.....I think I've hit on a super cheap way to get a nice Round Speedo using the standard Sierra module and ANY old 100mm DIA clock.

I extracted the speedo bit out of the Sierra Intrument Pod (see pikkie in my archive) then I got an old speedo and cut the bezel off about 10mm fom

the end. (I had one in my bits box but you could get an old knacker from an autojumble for a fiver) and, as I said ANY 100m DIA clock will do.

This was then sprayed matt black and affixed in the hole in the dash with three tiny screws and copiuos amounts of araldite (also see archive). The

Sierra Module was then fixed to the back of the dash held by four clips over the edge of it and screwed.

Say what you like but I think it looks ok and it cost nowt.(true LOCOST ) Plus its the standard car instrument which should please Mr SVA.

Shame the other clocks cost nearly £100 !!!!

Cheers

Jonti

[Edited on 21/3/04 by jonti]

Rescued attachment Padded-Dash in place.JPG

OFROK

|

|

|

|

|

JoelP

|

| posted on 21/3/04 at 06:52 PM |

|

|

no arguments with that jonti, ive squished the old speedo into a tight hole in the dash, didnt think to get a bezel for it but thats any easy way to

tidy it up.

|

|

|

Kitlooney1000

|

| posted on 21/3/04 at 08:26 PM |

|

|

problems is that the bezel you have used doesnt look like it will pass thr SVA radius test. but i might be wrong. bloody good idea though

|

|

|

gjn200

|

| posted on 21/3/04 at 08:30 PM |

|

|

er I think odear!! I've got a racetech gauge and the bezel wont pass SVA. Admittidly its hard to tell how much its recessed in the padding from

your pic.

<- Me!

|

|

|

jonti

|

| posted on 21/3/04 at 08:59 PM |

|

|

Speedo and Tacho are well recessed actually you can put a straight edge across without touching the bezels.

You're right though, the racetech ones do stick up a bit.

Thought I might make an additional, sort of padded 'mask' to fit over all of them for SVA if I needed too though.

OFROK

|

|

|

givemethebighammer

|

| posted on 21/3/04 at 09:21 PM |

|

|

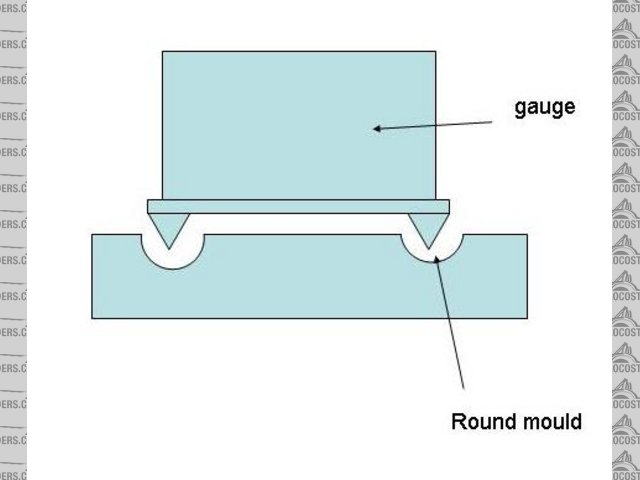

Nice one, my smiths gauges don't meet MR SVA's approval. I was thinking of moulding some rounded bezel covers using black silicone or car

filler.

Not worked out exactly how to do this but making moulds from plasticene or clay would seem possible. Or even allowing the car filler to go off enough

to be workable like clay ?

Rescued attachment bezel.JPG

|

|

|

paulf

|

| posted on 21/3/04 at 10:02 PM |

|

|

Why not just fit the guages into the exempt area, which is anywhere behind and to the right of the steering wheel ,and an amount i cant remember to

the left of the wheel of about 120mm.

Paul.

quote:

Originally posted by givemethebighammer

Nice one, my smiths gauges don't meet MR SVA's approval. I was thinking of moulding some rounded bezel covers using black silicone or car

filler.

Not worked out exactly how to do this but making moulds from plasticene or clay would seem possible. Or even allowing the car filler to go off enough

to be workable like clay ?

|

|

|

jonti

|

| posted on 21/3/04 at 10:51 PM |

|

|

I thought about getting a sheet of black squidgy rubber mat and making a mask to fit over the intrument cluster with holes cut slightly smaller than

the bezels. this could be stuck on with double sided tape then peeled off after SVA.

D'yer think it might work ? Or is this just a cynical dodge of which I should be ashamed ?

quote:

Originally posted by paulf

Why not just fit the guages into the exempt area, which is anywhere behind and to the right of the steering wheel ,and an amount i cant remember to

the left of the wheel of about 120mm.

I'd need a bloody big wheel to cover that lot I fear !

[Edited on 21/3/04 by jonti]

OFROK

|

|

|

gjn200

|

| posted on 21/3/04 at 11:46 PM |

|

|

You should be applauded

<- Me!

|

|

|

Fifer

|

| posted on 22/3/04 at 01:56 PM |

|

|

I like givemethebighammer's idea. If someone could make something like this in various diameters with the correct radius on the face and a

groove on the back to take most sharp bezels, these could be stuck on for the SVA man then removed (or not if they look good !) after test !

|

|

|

jonti

|

| posted on 22/3/04 at 08:02 PM |

|

|

I agree but they'd have to be bespoke I think....

No two clocks manufacturers seem to use the same bezel.

OFROK

|

|

|

stephen_gusterson

|

| posted on 22/3/04 at 09:03 PM |

|

|

i have some nice guages that have illegal bezels.

I am gonna make up either a plastic cover sheet or use the padded idea.

atb

steve

|

|

|

givemethebighammer

|

| posted on 22/3/04 at 10:36 PM |

|

|

Bought some black silicone today, think I may have ago at making some covers this weekend..... or making a right mess, whatever I will keep you

informed !!!!

|

|

|

jonti

|

| posted on 22/3/04 at 10:49 PM |

|

|

Be interested in seein' how you get on chuck make sure you let us know...

Wonder if there's such a thing as half round self adhesive rubber strip ?

Boat chandlers maybe ?....mmmm.......might check that one out.

OFROK

|

|

|

Alan_Thomas

|

| posted on 23/3/04 at 12:45 PM |

|

|

quote:

Originally posted by givemethebighammer

Nice one, my smiths gauges don't meet MR SVA's approval. I was thinking of moulding some rounded bezel covers using black silicone or car

filler.

You might want to look up the thread I posted on this search for 'Smiths Instruments'

|

|

|

britishtrident

|

| posted on 25/3/04 at 01:47 PM |

|

|

The moral is put they car through SVA with a minimum of dials and switches all in the "safe zone" and add extra dials after SVA.

|

|

|

James

|

| posted on 25/3/04 at 02:31 PM |

|

|

Looking good Jonti!

Britishtrident,

Just out of interest- your profile's a bit sparse- what are you building? Locost? Kit? Or still deciding? Would be cool to see some pictures.

Cheers,

James

|

|

|

givemethebighammer

|

| posted on 13/4/04 at 04:11 PM |

|

|

Update

Tried to mould a new bezel from body filler using plasticene as a mould.

New new bezel came out the right shape and looked OK, except the plasticene has stuck all over it and looks impossible to completely clean off without

breaking the new bezel. Pain as I was intending to spray the finished article matt black.

So... looking for something better to make a mould out of, I have thought maybe clay ?

|

|

|

James

|

| posted on 16/4/04 at 09:58 AM |

|

|

What about modelling putty?

Back in the day I used to use some stuff called 'Milliput'. It's two part and lovely to work with. When hard is file/sandable if

need be too.

It wasn't barry bargain cheap but cheap enough! Local modelling shop should be able to help you.

HTH,

James

|

|

|

ned

|

| posted on 16/4/04 at 10:42 AM |

|

|

how about putting a thin layer of grease and some cling film so the stuff doesn't stick to the mould. Not a tried and tested combination on my

part, but there must be something that you can use to stop the mould sticking to the workpiece.

Ned.

beware, I've got yellow skin

|

|

|

DaveFJ

|

| posted on 16/4/04 at 12:17 PM |

|

|

How about using Flexane? it's a rubber compound available from Frosts and as long a your 'mould' has some release agent (wax?) it

gives a really good result.

Dave

"In Support of Help the Heroes" - Always

|

|

|