Welding Jig

Dick Axtell - 18/1/05 at 05:16 PM

....for LOWER wishbones.

Yes, I know it's a long shot, just hoping someone's done some prep already.

TIA

nige - 18/1/05 at 05:36 PM

is this for fitting or fabbing up

either way we made ours out of 1" ply

Dick Axtell - 18/1/05 at 08:48 PM

quote:

Originally posted by nige

is this for fitting or fabbing up

either way we made ours out of 1" ply

For fabricating/welding.

How did you limit welding heat effects on the ply?

And have you any pics or drawings, of ur jig?

[Edited on 18/1/05 by Dick Axtell]

nige - 18/1/05 at 09:52 PM

didnt burn much

will dig it out and take some piccys

Mix - 19/1/05 at 09:59 AM

I turned up two sets of dummy bushes from tufnol and using these and 12mm threaded rod set the width of the bone. A piece of 25x25 drilled at right

angle was threaded onto the rod between the buses and secured in the correct position by nuts and then the ball joint plate was clamped to this for

welding. Worked fine, made the upper bones in a similar fasion but used a second threaded rod welded to a nut and running at 90 degrees to the first

and a couple of dummy bushes to set the ball joint tube.

Hope this makes sense

Mick

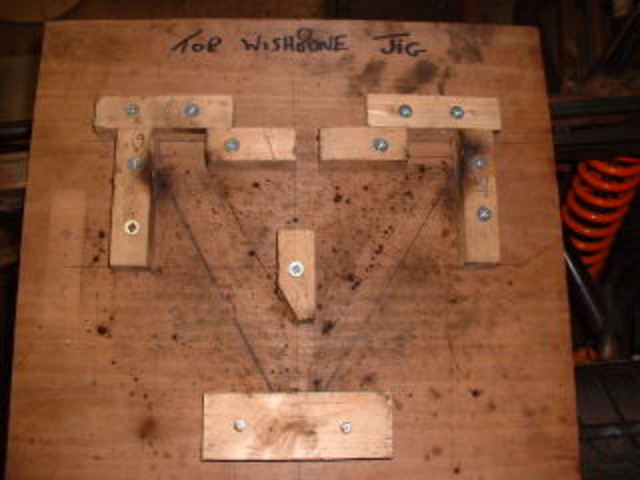

nige - 19/1/05 at 08:33 PM

cant find bottom jig

but its much like top

laid bush tube,s in and pack arms up to centreline with welding rod

tacked up checked... turned over tacked put back in jig checked ... welded up

and rechecked ......... "job,s a good un"

p.s check my archive dick .... see your old nosecone

Rescued attachment jig3.JPG

Dick Axtell - 20/1/05 at 11:09 AM

Mix & Nige,

Thanks for the tips, and the pic. Now I need some 1" ply (or some old kitchen worktop??).

Reckon there will have to be some 90 deg brkts, for the centring rod, for mounting the bushing sleeves.

Cheers, guys!

Mix - 20/1/05 at 11:21 AM

Dick

My method for the upper bones

Mick

Rescued attachment Locost pics 002.jpg