blakep82

|

| posted on 14/2/10 at 09:01 PM |

|

|

body filler

i was watching american hotrod last night, and it was the one with the 1940's ford (that or the '44'... i couldn't really

tell) and when they came to do the filling, they had this bright green filler, that went on so easily, and fairly runny. they smeared it into a corner

with their fingers, and could run their finger along the panel about 1ft per second

anyone know what this stuff is? i've been using U-pol, and find it really thick, and a bit too hard to work with sometimes. and it keeps

sticking to my gloves.

any other recommendations?

________________________

IVA manual link http://www.businesslink.gov.uk/bdotg/action/detail?type=RESOURCES&itemId=1081997083

don't write OT on a new thread title, you're creating the topic, everything you write is very much ON topic!

|

|

|

|

|

Benzine

|

| posted on 14/2/10 at 09:08 PM |

|

|

quote:

Originally posted by blakep82

i was watching american hotrod last night, and it was the one with the 1940's ford (that or the '44'... i couldn't really

tell) and when they came to do the filling, they had this bright green filler, that went on so easily, and fairly runny. they smeared it into a corner

with their fingers, and could run their finger along the panel about 1ft per second

anyone know what this stuff is? i've been using U-pol, and find it really thick, and a bit too hard to work with sometimes. and it keeps

sticking to my gloves.

any other recommendations?

I was talking to my cousin who works at a bodyshop and he referred to it as "u-concrete". I can't remember what he said they used

but it was better and cheaper. I always get annoyed at those programs on tv, it goes on so smooth with no bubbles or dimples

|

|

|

RAYLEE29

|

| posted on 14/2/10 at 09:09 PM |

|

|

are you using upol c or the fine easy sanding stuff, upol extra the last last time i bought some.

all i can say is i like the fine stuff and anythings better than p38 or plastic padding you can get bodyline filler but ive never tried it worth

asking at the local body/paint shop what they use/recommend

Ray

|

|

|

blakep82

|

| posted on 14/2/10 at 09:11 PM |

|

|

lol u-concrete

its goes on so thick you end up sanding most of it off! if you try to do thin layers, it sticks to the 'spreader' (?) and pulls right back

off again!

________________________

IVA manual link http://www.businesslink.gov.uk/bdotg/action/detail?type=RESOURCES&itemId=1081997083

don't write OT on a new thread title, you're creating the topic, everything you write is very much ON topic!

|

|

|

boggle

|

| posted on 14/2/10 at 09:12 PM |

|

|

topstop in the red tin.....best you can get imho....

just because you are a character, doesnt mean you have character....

for all your bespoke parts, ali welding, waterjet, laser, folding, turning, milling, composite work, spraying, anodising and cad drawing....

u2u me for details

|

PLEASE NOTE: This user is a trader who has not signed up for the LocostBuilders registration scheme. If this post is advertising a commercial product or service, please report it by clicking here.

|

blakep82

|

| posted on 14/2/10 at 09:19 PM |

|

|

where would i get topstop? can i get it from the likes of halfords? or more specialist?

i'll try my local paint suppliers. the guy in there's pretty cool

here's what i got

Description

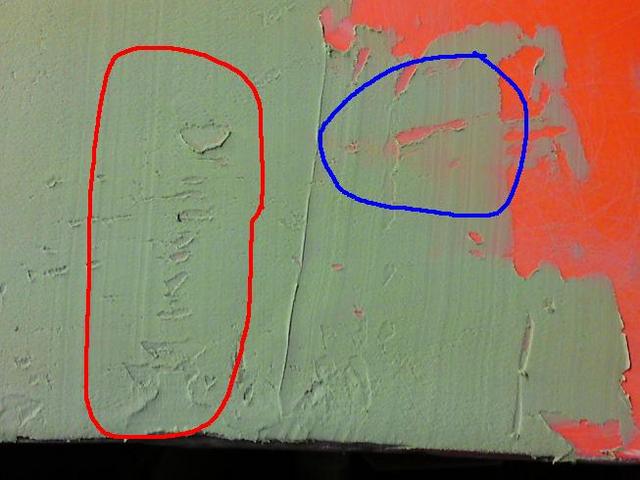

and here's what it does

Description

it drags (red)

and pulls off (blue)

ok, so i didn't want it where the blue line is anyway, and thats why the paint is still so smooth so that won't have helped, but its a pain

in the bottom

________________________

IVA manual link http://www.businesslink.gov.uk/bdotg/action/detail?type=RESOURCES&itemId=1081997083

don't write OT on a new thread title, you're creating the topic, everything you write is very much ON topic!

|

|

|

StrikerChris

|

| posted on 14/2/10 at 09:23 PM |

|

|

just mix some fiberglass resin in with it,halfrauds sell it in small quantities,flows far smoother,goes alot further and gives you more time,goes off

with the normal hardener

|

|

|

blakep82

|

| posted on 14/2/10 at 09:24 PM |

|

|

ah, so you can just thin it? nothing to lose. if it ruins it i'll just buy some more (better) stuff!

i'll gove that a shot thanks

________________________

IVA manual link http://www.businesslink.gov.uk/bdotg/action/detail?type=RESOURCES&itemId=1081997083

don't write OT on a new thread title, you're creating the topic, everything you write is very much ON topic!

|

|

|

tomgregory2000

|

| posted on 14/2/10 at 09:24 PM |

|

|

in america its called BONGO

|

|

|

RAYLEE29

|

| posted on 14/2/10 at 09:25 PM |

|

|

it doesnt like the cold weather is your work area cold?

Ray

|

|

|

blakep82

|

| posted on 14/2/10 at 09:28 PM |

|

|

quote:

Originally posted by RAYLEE29

it doesnt like the cold weather is your work area cold?

Ray

freezin'

about 8 degrees outside i'd say, but i do have a heater on...

i find it hard to work with in the summer too right enough.

________________________

IVA manual link http://www.businesslink.gov.uk/bdotg/action/detail?type=RESOURCES&itemId=1081997083

don't write OT on a new thread title, you're creating the topic, everything you write is very much ON topic!

|

|

|

boggle

|

| posted on 14/2/10 at 09:38 PM |

|

|

you loose the elasticity if you mix resin with it....

just because you are a character, doesnt mean you have character....

for all your bespoke parts, ali welding, waterjet, laser, folding, turning, milling, composite work, spraying, anodising and cad drawing....

u2u me for details

|

PLEASE NOTE: This user is a trader who has not signed up for the LocostBuilders registration scheme. If this post is advertising a commercial product or service, please report it by clicking here.

|

blakep82

|

| posted on 14/2/10 at 09:42 PM |

|

|

^ ah, thats true... it would be a bit brittle i suppose...

________________________

IVA manual link http://www.businesslink.gov.uk/bdotg/action/detail?type=RESOURCES&itemId=1081997083

don't write OT on a new thread title, you're creating the topic, everything you write is very much ON topic!

|

|

|

tomprescott

|

| posted on 14/2/10 at 09:45 PM |

|

|

I've always used isopon, p38 and p40, one has fibre based in and the other is easy-sand, I've found that ambient temp can have quite an

effect on the ease of use as they are thermogenic. Easily available and when you mix it well you can achieve very good results.

|

|

|

boggle

|

| posted on 14/2/10 at 09:47 PM |

|

|

this is the stuff....

just because you are a character, doesnt mean you have character....

for all your bespoke parts, ali welding, waterjet, laser, folding, turning, milling, composite work, spraying, anodising and cad drawing....

u2u me for details

|

PLEASE NOTE: This user is a trader who has not signed up for the LocostBuilders registration scheme. If this post is advertising a commercial product or service, please report it by clicking here.

|

blakep82

|

| posted on 14/2/10 at 09:49 PM |

|

|

ah, yeah, i'll be able to get that easy enough. i'll give it a shot

don't think i've got a huge amount of body work to do, but will be an better finish if i've got a decent filler to work with. all my

body work is very 2nd hand  (race 2nd hand, some panels broken completely in 2!) (race 2nd hand, some panels broken completely in 2!)

________________________

IVA manual link http://www.businesslink.gov.uk/bdotg/action/detail?type=RESOURCES&itemId=1081997083

don't write OT on a new thread title, you're creating the topic, everything you write is very much ON topic!

|

|

|

deltron63

|

| posted on 14/2/10 at 10:13 PM |

|

|

what ever filler you use, put it on with a metal spreader, it'll go on a lot smoother.( 25 years doing body work)!!

|

|

|

Humbug

|

| posted on 14/2/10 at 10:25 PM |

|

|

quote:

Originally posted by tomgregory2000

in america its called BONGO

...I think you'll find it's Bondo, not Bongo...

|

|

|

boggle

|

| posted on 14/2/10 at 10:26 PM |

|

|

sorry dont agree....

i find a decent soft plasic filler spreader better and you can shape it if your are going between curves....i think the art of filling is more to do

with your ability to feel the pannell surface before and after to keep your block rubbing flat...if you are worried its best to add too much and rub

back......

i find that if you put a bit of tissue under your hand and rub across the pannell you will feel any deveations in the surface...its something that

takes time and practice....

just because you are a character, doesnt mean you have character....

for all your bespoke parts, ali welding, waterjet, laser, folding, turning, milling, composite work, spraying, anodising and cad drawing....

u2u me for details

|

PLEASE NOTE: This user is a trader who has not signed up for the LocostBuilders registration scheme. If this post is advertising a commercial product or service, please report it by clicking here.

|

andrew-theasby

|

| posted on 14/2/10 at 10:38 PM |

|

|

last time i did some filling, it was freezing and the filler was really stiff. so i got the paint stripper gun out and gave it a waft with that just

to see. Only a second or two on the spatuler but what a difference that made. It was miles better. I use a perspex scraper for flat things, but

agree a softer one would be best for curves. HTH

|

|

|

blakep82

|

| posted on 14/2/10 at 10:53 PM |

|

|

i've only got plastic spreaders at the moment, so they're what i'll use

round 2 in a minute, so i'll try heating the filler with a heat gun before i use it. see how i get on.

cheers everyone! some ideas to keep me going there  hopefully i won't have too much filling to do on this car lol hopefully i won't have too much filling to do on this car lol

________________________

IVA manual link http://www.businesslink.gov.uk/bdotg/action/detail?type=RESOURCES&itemId=1081997083

don't write OT on a new thread title, you're creating the topic, everything you write is very much ON topic!

|

|

|

hicost blade

|

| posted on 14/2/10 at 11:00 PM |

|

|

I find by far the best spreader is an old credit/bank card.....

BTW you people do know all of these fillers are just a polyester resin with talc to thicken in up don't you? So it will have all the same

behaviour....

|

|

|

Peteff

|

| posted on 14/2/10 at 11:13 PM |

|

|

You need more practise, that's all and rub it down with some 80 grit first layer so the second layer keys better and goes on thinner just to

fill the scratches. Don't let your applicator whatever you use get too flat to the surface and keep the edge of it clean. Don't heat the

filler before you use it, you could warm the surface it's going on then warm the filler after it's on there. My favourite spreader is a

piece of thin shim steel, it flexes the filler back off when it hardens so it keeps a good edge.

[Edited on 15/2/10 by Peteff]

yours, Pete

I went into the RSPCA office the other day. It was so small you could hardly swing a cat in there.

|

|

|

blakep82

|

| posted on 15/2/10 at 01:39 AM |

|

|

warmer garage didn't work very well, and warming the panel seems to make it go hard faster. also use a old loyalty card as a spreader since it

was extra flexable. didn't really come up much better, but a little bit more sanding should see the right shape. i think about 70% of the filler

i put on ends up sanded back off again lol

true enough its all in the practise though. its much better than my first attempts at it all those years ago lol

________________________

IVA manual link http://www.businesslink.gov.uk/bdotg/action/detail?type=RESOURCES&itemId=1081997083

don't write OT on a new thread title, you're creating the topic, everything you write is very much ON topic!

|

|

|

boggle

|

| posted on 15/2/10 at 10:18 AM |

|

|

we need pics!!!!

just because you are a character, doesnt mean you have character....

for all your bespoke parts, ali welding, waterjet, laser, folding, turning, milling, composite work, spraying, anodising and cad drawing....

u2u me for details

|

PLEASE NOTE: This user is a trader who has not signed up for the LocostBuilders registration scheme. If this post is advertising a commercial product or service, please report it by clicking here.

|