2cv

|

| posted on 18/10/10 at 02:54 PM |

|

|

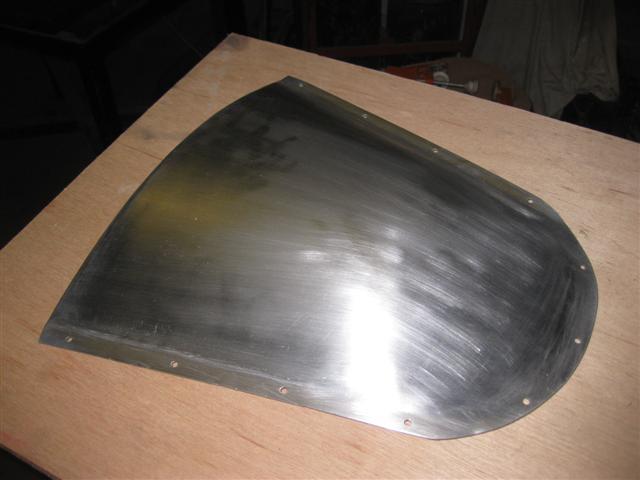

Making an Aluminium Bonnet Scoop: step by step pictures

As with many things in life there are often a number of ways to achieve the same object and metal shaping is no exception. There are no right or wrong

ways, you just find a method that works for you.

Hammerforming works for me and that's the way I'm tackling the bonnet air scoop.

As with the power bulge covered in a previous thread, the desired shape was cut out of two pieces of 12mm ply, the upper piece being about 10mm larger

all round than the lower piece. This time I'm using 1.5mm thick pure aluminium 1050A and have not annealed it. The aluminium was sandwiched

between the two pieces of ply and screwed together to stop any movement.

In the un-annealed state the aluminium was a lot harder to work and so I used the soft head of a Thor hammer to get some shape into it.

I covered the planishing stage in the previous thread and this was done in exactly the same way.

Here are some early stage pictures.

[img]

Description

[/img]

[img]

Description

[/img]

[img]

Description

[/img]

[img]

Description

[/img]

[img]

Description

[/img]

[img]

Description

[/img]

[img]

Description

[/img]

[Edited on 18/10/10 by 2cv]

[Edited on 18/10/10 by 2cv]

|

|

|

|

|

Ivan

|

| posted on 18/10/10 at 03:04 PM |

|

|

I just have to try this some time I just have to try this some time

|

|

|

2cv

|

| posted on 18/10/10 at 03:15 PM |

|

|

I warn you, it is addictive!!

|

|

|

flak monkey

|

| posted on 18/10/10 at 03:20 PM |

|

|

Excellent stuff, missed your previous installments and just went back and had a look

You have more patience that me, thats for sure. I have always wanted to give it a go though!

Sera

http://www.motosera.com

|

|

|

2cv

|

| posted on 18/10/10 at 03:25 PM |

|

|

I'm not patient at all but I don't think you need patience to do something you enjoy.

|

|

|

Daddylonglegs

|

| posted on 18/10/10 at 03:58 PM |

|

|

Nice one!

Always someone giving great advice on here

It looks like the Midget is winning at the moment......

|

|

|

2cv

|

| posted on 19/10/10 at 12:05 PM |

|

|

After planishing out the dents and blemishes caused by the hammering the next step is to form a safe edge on the front lip. After trimming off and

squaring up the flange a pencil line is made 10mm in from the edge. Using glaziers pliers the edge is progerssively turned over to as far as you can

go. The rest of the way is taken care of with a cross pein hammer.

[img]

Description

[/img]

[img]

Description

[/img]

[img]

Description

[/img]

[img]

Description

[/img]

[img]

Description

[/img]

|

|

|

2cv

|

| posted on 19/10/10 at 12:27 PM |

|

|

Once you have broken the line, the aluminium will always bend along that line.

[img]

Description

[/img]

[img]

Description

[/img]

[img]

Description

[/img]

|

|

|

2cv

|

| posted on 19/10/10 at 12:45 PM |

|

|

The last job was to punch 4mm mounting holes for either rivets or screws.

The great thing about a Hammerform is that it can be cut to the exact shape and size to suit the job and the finshed component will be exactly the

right size.

|

|

|

MikeR

|

| posted on 19/10/10 at 02:17 PM |

|

|

thank you - you're giving me inspiration for when i finally replace my crossflow with a zetec.

|

|

|

2cv

|

| posted on 19/10/10 at 02:50 PM |

|

|

That's really good news Mike, I'm very pleased that this has been a help to you.

|

|

|

2cv

|

| posted on 22/10/10 at 07:05 AM |

|

|

Just to bring the three threads to a conclusion, the following parts can be easily made using just the normal hand tools that most of us will have in

the workshop. The parts being, bonnet air scoop, power bulge and Dellow type heat extaction flutes.

They are all easy to make and in my opinion look good.

I hope these three "How To" topics will be an encouragement for others to have a go themselves and discover the delights of metal

shaping.

[img]

Description

[/img]

[img]

Description

[/img]

[img]

Description

[/img]

[Edited on 22/10/10 by 2cv]

|

|

|

steve m

|

| posted on 22/7/11 at 10:03 AM |

|

|

yesterday, i had a second attempt at making a bonnet hump to replace my sad looking fiberglas one that has been in the wars, and lost!

my main queston , is that now i have the shape i want, how do i get all the little bumps out?, i have tried and tried to no avail!

The current setup

The new bump just laid over the old one,, it needs cutting down, but the shape is there

As it is right now, waiting for the final bump removal and then polishing

|

|

|

2cv

|

| posted on 22/7/11 at 11:44 AM |

|

|

Hi Steve, That looks really good. You managed to put a lot of shape in and I know how much effort it takes to do that. I can also imagine your

satisfaction at having done it. Will you be putting a flange on for fixing the bulge to the bonnet?

There are two ways to remove the bumps. One is using a dolly and a slapper and the other is with an English wheel. If you take the first method, the

dolly will need to have a slightly greater radius than the bulge and the slapper can be made from an old heavy flat file first heated and bent and

then the serrations removed. The idea is to bring the low spots up by stretching. You then need to use a body file at the finishing stage to take out

the highs. Wherever there is any feathering (small cracks) around the edge these need to be trimmed off to avoid the cracks spreading further.

U2U sent.

|

|

|