MikeR

|

| posted on 5/5/20 at 03:36 PM |

|

|

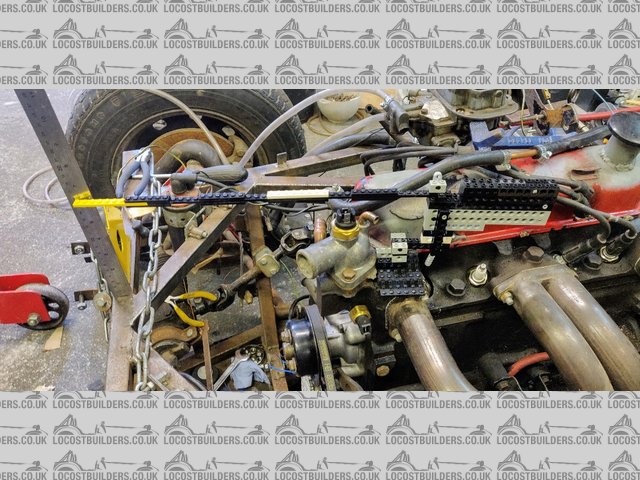

budget / emergency dial gauge (Lego)

So I couldn't shake the concern of messed up calculating tdc. I don't have a dial gauge so had shoved a bit of copper pipe down plug #1

& watched it move as I rotated the crank. Marking where it stopped and started moving. Tdc being in the middle.

We'll as I couldn't shake this I thought I need to make my own dial gauge. 20 minutes with the technical Lego and.....

Lego dial

Worked perfectly, ended up with a weight on the base so I was sure it wouldn't fall off but in 2 minutes I proved I had tdc perfect. Now why

aren't my kids interested in doing Lego with me?

|

|

|

|

|

steve m

|

| posted on 5/5/20 at 04:15 PM |

|

|

Boys and there toys ??

I use and old spark plug with the ceramic smashed or drilled out with a rod with the end rounded off so it slides across the piston better

doesn't matter how you do it, as long as the result comes out that you want

steve

Thats was probably spelt wrong, or had some grammer, that the "grammer police have to have a moan at

|

|

|

nick205

|

| posted on 5/5/20 at 04:26 PM |

|

|

Fantastic work!

Lego is truly a great thing.

|

|

|

rusty nuts

|

| posted on 5/5/20 at 05:40 PM |

|

|

Iíve also used an old spark plug at times , broke out the ceramic and removed the electrodes then welding in an old bolt. Screwed into the plug hole

and slowly turned the engine over until the piston hit the bolt, marked the crank pulley then rotated the engine backwards marked the pulley again the

measured between the two marks and divided by 2 gives an accurate TDC

|

|

|

daviep

|

| posted on 5/5/20 at 09:44 PM |

|

|

quote:

Originally posted by rusty nuts

Iíve also used an old spark plug at times , broke out the ceramic and removed the electrodes then welding in an old bolt. Screwed into the plug hole

and slowly turned the engine over until the piston hit the bolt, marked the crank pulley then rotated the engine backwards marked the pulley again the

measured between the two marks and divided by 2 gives an accurate TDC

+1

No need to try and judge when movement has stopped, much simpler / more reliable method.

ďA truly great library contains something in it to offend everyone.Ē

|

|

|