Mr Whippy

|

| posted on 12/1/09 at 11:47 AM |

|

|

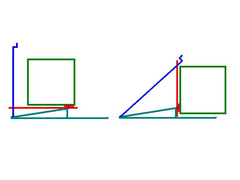

Car rotating frame

Hi

Been thinking, Iím needing one or two of the cars put on their side to sort the floors out and looking on the web I see you can buy for about £5, 3m

long M10 threaded rod. I also have tones of scaffolding lying around so I drew up this idea to safely rotate the cars over. Given the leverage and the

light weight of the cars (the beach buggy is one of them) the tension on the treaded rod would be very low. Course it would take a while to do it due

to the length of the thread so thought of adding a handle to the end of each  Due to the design of the cars, neither the front or the back of the

body can take the weight (or in the case of the buggy there is no back) of a shell hence two of these things would be bolted onto the hubs and two

bars would tie the two lifters together. Due to the design of the cars, neither the front or the back of the

body can take the weight (or in the case of the buggy there is no back) of a shell hence two of these things would be bolted onto the hubs and two

bars would tie the two lifters together.

Obviously this is just a super basic (not close to scale) concept sketch but what do you think?

[Edited on 12/1/09 by Mr Whippy]

Rescued attachment car rotator.JPG

|

|

|

|

|

Steve P

|

| posted on 12/1/09 at 12:05 PM |

|

|

Are they a bare shell? just curious as not sure if 10mm up to the job.

|

|

|

MikeR

|

| posted on 12/1/09 at 12:06 PM |

|

|

That seems like a lot of weight on the hubs / bearings when the car is lying on its side.

You'll also have the issue of stuff weeing out of holes when on its side (i'm assuming you'll remove the engine but what about oil

in the diff housing of RWD live axle cars?)

|

|

|

Mr Whippy

|

| posted on 12/1/09 at 12:10 PM |

|

|

Pretty much bare shells, but that is almost a 2m leverage...

I donít mind going to M12 if that was what was needed but kind of think thatís an overkill. I have actually done this before on a beetle about 15

years ago, no issues at all with the hub bearings (I tightened them up fully before hand) and replaced the dampers with two lengths of tube to lock

the suspension. The last time it was a much more basic roll the thing over using an engine crane and was a tab dangerous tbh. As you say the oil had

to be drained out but thatís a 5 minute job anyway.

[Edited on 12/1/09 by Mr Whippy]

|

|

|

ReMan

|

| posted on 12/1/09 at 12:16 PM |

|

|

No. I'm not convinced that threaded rod woud be strong enough at that size, particularly as its' not best qyality steel.

The rest of the idea looks good though.

Up the size to 14/16/18 for a couple of quid more

You can get 18mm HT for £15!

|

|

|

Mr Whippy

|

| posted on 12/1/09 at 12:19 PM |

|

|

ok I can still deal with M18 since I will just use nuts instead of cutting threads. Seems a dead easy thing to make really. ta

|

|

|

matt_claydon

|

| posted on 12/1/09 at 12:37 PM |

|

|

quote:

Originally posted by MikeR

That seems like a lot of weight on the hubs / bearings when the car is lying on its side.

No more than when cornering at 1g.

These things are available comercially, just google "car tilter". eg:

http://www.cjautos.org.uk/phdi/p1.nsf/supppages/cjautos?opendocument&part=3

M10 would be probably be strong enough depending on the grade but I'd go M18-M20 for the safety factor and because it'll be half as many

turns on the handle!

I'd build in some kind of locked prop or support for once it's in position just to be safe.

|

|

|

Mr Whippy

|

| posted on 12/1/09 at 12:52 PM |

|

|

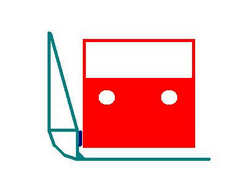

that one at the top pic looks almost identical to the first one I made but at -

BASIC BODY ROLLER

Price: £365.00 + VAT + P&P

I was thinking more along £50 to build one

|

|

|

mcerd1

|

| posted on 12/1/09 at 01:08 PM |

|

|

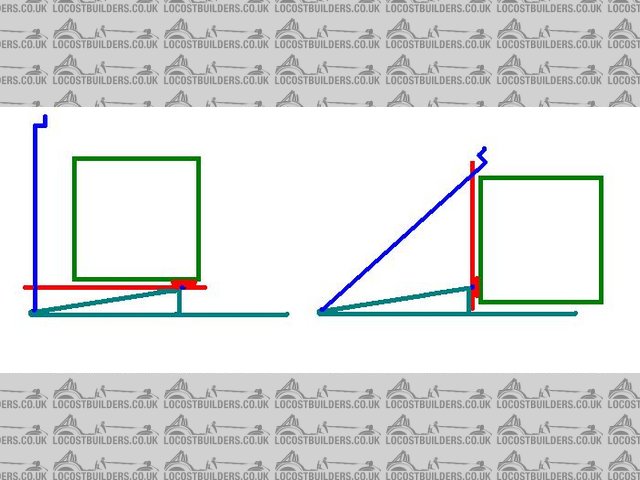

you mean this type:

I've been thinking about making a basic one of these for a while:

I recon you could make a locost version quite easily - probably using a couple of old hubs

it wouldn't be as adjustable as the £800 one - but if you make it to fit your car(s) why would it matter

|

|

|

Mr Whippy

|

| posted on 12/1/09 at 01:22 PM |

|

|

the first one I made was like this but like I said a little scary to lower and raise the car. The 'new' one would do it far more safely and

controlled. It was just made of angle section and scaffold tube, cost peanuts thb and held the car on its side in the garage for about half a year

with no effect on the wheel bearings. The curve was simply several cuts rewelded in the angle section.

[Edited on 12/1/09 by Mr Whippy]

Rescued attachment first.JPG

|

|

|

speedyxjs

|

| posted on 12/1/09 at 05:53 PM |

|

|

quote:

Originally posted by matt_claydon

These things are available comercially, just google "car tilter". eg:

http://www.cjautos.org.uk/phdi/p1.nsf/supppages/cjautos?opendocument&part=3

But thats not the locost way

How long can i resist the temptation to drop a V8 in?

|

|

|

Fred W B

|

| posted on 12/1/09 at 06:07 PM |

|

|

quote:

Course it would take a while to do it due to the length of the thread so thought of adding a handle to the end of each

How about adding a suitable fitting or just a nut welded on and drive it with a socket on a drive chucked into a hand held drill machine?

Cheers

Fred W B

You can do it quickly. You can do it cheap. You can do it right. Ė Pick any two.

|

|

|

Dale

|

| posted on 13/1/09 at 12:49 PM |

|

|

When I was welding up my floor I just welded a piece of round tube at the pivot point in the front and a bar at the back and used my engine stand

which rotates and made a stand for the other end of the car with a bolt the right size to go through the tube at the other end. It worked quite

nicely but was only turning less than 200 lbs

Dale

Thanks

Dale

my 14 and11 year old boys 22

and 19 now want to drive but have to be 25 before insurance will allow. Finally on the road

|

|

|