albertz

|

| posted on 16/5/04 at 06:56 PM |

|

|

Sidepanels

What have most people done regarding side panels i.e. have you made them one piece from front to rear, or in two sections as per the book with a line

of rivets?

Cheers

Albertz.

|

|

|

|

|

JoelP

|

| posted on 16/5/04 at 07:08 PM |

|

|

mines not book, its got flat sides, but i did one piece of 18g/22g (cant remember which) welded in fully. looks a bit industrial but works well.

|

|

|

Hellfire

|

| posted on 16/5/04 at 09:02 PM |

|

|

We've got FG panels and we have PU adhesive'd them on.

|

|

|

Mark Allanson

|

| posted on 16/5/04 at 09:20 PM |

|

|

I did mine as per the book except for the front sections. If you can do yours in one go, you're a better man than me!

If you can keep you head, whilst all others around you are losing theirs, you are not fully aware of the situation

|

|

|

SeaBass

|

| posted on 16/5/04 at 09:36 PM |

|

|

We manufactured ours in a single piece. It's perfectly doable just more of a fiddle. Make up a decent template and you'll be fine.

http://www.bass2dark.freeserve.co.uk/170703/170703.htm

Cheers

|

|

|

ray.h.

|

| posted on 16/5/04 at 11:09 PM |

|

|

We made up cardboard templates and moved the holes around untill they all looked ok.Not hard but very time consuming but it meant the stainless ones

fitted first time,thank god.

|

|

|

DavidM

|

| posted on 16/5/04 at 11:16 PM |

|

|

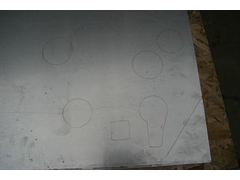

One piece in 1.5 mm aluminium. Make all the mistakes on cardboard templates and grow a couple of extra pairs of hands and it's easy.

Rescued attachment P1010075.JPG

|

|

|

albertz

|

| posted on 17/5/04 at 07:05 AM |

|

|

Thanks for the help. I have made a cardboard template for each side and hopefully it should be a case of transferring it onto the Zintec (using 1.0

Zintec as a replacement for the expensive Alu).

On the front section of the side panel, at the bottom edge, have you radiused it, or bent it to form a right angle? On my templates i have bent it to

right angle, but i am noticing that some people have radiused this area instead. Is there any particular reason for that? cosmetics, simplicity?

Albertz

|

|

|

redeye

|

| posted on 17/5/04 at 12:06 PM |

|

|

did mine in one piece aswell

looks better than i line of rivets down the side

i also radiused the bottom, just looks better i reckon

Rescued attachment 119-1909_IMG.JPG

|

|

|

DavidM

|

| posted on 18/5/04 at 08:19 PM |

|

|

Neither, did mine at 45 degrees.

ish!

[Edited on 18/5/04 by DavidM]

|

|

|