blakep82

|

| posted on 3/12/14 at 11:48 PM |

|

|

extending a fuel rail

Ok, so i've been busy and spent a bit of time not even looking at the car, electrics and efi to do and just needed time away from it

I needed to respace the itbs, done. Now need to extend the fuel rail. Speaking to a tig welding lecturer at college who's happy to weld it for

me, its steel, only needs extended by 4mm or so. Looks to be 12mm o.d, and looking at the end of it, I think its 8mm I.d so wall of 1.5mm

It could be sleeved outside and welded. Or could I extend it with a small piece of fuel hose, clamped with proper fuel hose clamps.

I'd prefer it to be welded, but theres a risk of pin holes leaking. Hose would work, but why have I never seen anyone extend a rail with

hose?

Thoughts?

________________________

IVA manual link http://www.businesslink.gov.uk/bdotg/action/detail?type=RESOURCES&itemId=1081997083

don't write OT on a new thread title, you're creating the topic, everything you write is very much ON topic!

|

|

|

|

|

mark chandler

|

| posted on 4/12/14 at 12:00 AM |

|

|

Classic rangerovers, SIII jags etc had stubby little hoses from the fuel rail to the injectors, no reason why not I suspect it's just cheaper to

manufacture stuff more accurately these days.

|

|

|

Andybarbet

|

| posted on 4/12/14 at 12:25 AM |

|

|

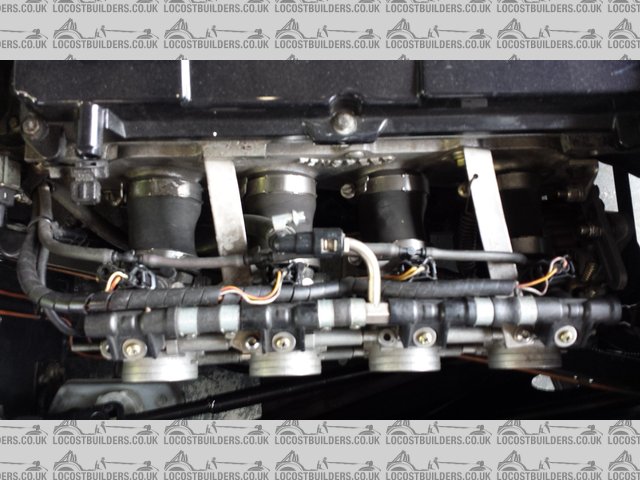

fuel rail

Here's one i saw at Donnington a few weeks ago on one of the kit manufacturers cars so it must work ok.

Give a man a fish & it will feed him for a day, give him a fishing rod & you've saved a fish.

|

|

|

blakep82

|

| posted on 4/12/14 at 01:00 AM |

|

|

Awesome, just never seen it before, but hose must be up to the pressure, thats what it does!

Andy that pic is kinda what I was thinking, except I only need to space out the middle by 4mm, 1 cut, 1 hose. And under pressure it can't go

anywhere.

Cheers lads

________________________

IVA manual link http://www.businesslink.gov.uk/bdotg/action/detail?type=RESOURCES&itemId=1081997083

don't write OT on a new thread title, you're creating the topic, everything you write is very much ON topic!

|

|

|

BenB

|

| posted on 4/12/14 at 08:35 AM |

|

|

External sleeve and a relatively copious amount of JB weld would be my option! Ain't going to be no pin hole leaks then and simple.

|

|

|

mark chandler

|

| posted on 4/12/14 at 09:20 AM |

|

|

File a couple of notches in the tube fior the hose to hang on and use decent clamps, it's not a problem.

|

|

|

sebastiaan

|

| posted on 4/12/14 at 06:49 PM |

|

|

I did this two weeks ago, also a 12mm OD rail with 1,5mm wall thickness. It's not off an R6 or R1, is it? I just cut the rail where it needed to

be extended, clamped the separated bits to a piece of angle iron and welded in small pieces of 12x1,5 hydraulic tubing with the MIG. A 1 hour job once

I stopped mulling and simply got on with it. Simples.

|

|

|