NS Dev

|

| posted on 1/11/06 at 12:59 PM |

|

|

Reference points in Megasquirt?

Not sure how to ask this question, its an extension of another thread but I thought best asked seperately.

I am investigating running a (well a pair) of vee twin bike engines using megasquirt with dizzyless ign control too.

how can I configure the ecu to run a 60 degree vee twin?

Retro RWD is the way forward...........automotive fabrication, car restoration, sheetmetal work, engine conversion

retro car restoration and tuning

|

|

|

|

|

MikeR

|

| posted on 1/11/06 at 01:06 PM |

|

|

There are yahoo groups for the megasquirt - that would probably be the best forum to ask the question (and find people who've done the same).

I'd also contact bill shurvington, tell him what you want to do, ask him can megasquirt cope / what do you need / can he point you at someone

who's done it to ask questions.

(bear in mind that bill does this as a hobby)

I'm assuming you're going to run the two engines off the one megasquirt. my only concern about this would be how tightly coupled the two

engines are, using chains to drive the rears would mean a degree of slop that would mean one engine wouldn't be firing at exactly the right

time.

Bill will sell you the kit to solder if up yourself and then if you can't get it to work, will sort out someone to look it over for you (for a

reasonable cost). Might be worth getting two kits which would work out about the same as one soldered up one.

What does the V rev too? you'll have to use MS3 as i'm sure they are over 10k, not sure how high the MS3 will rev, i've got a number

in my head but i've no idea how accurate it is. There is no issue with MS driving v6, v8 or flat's so in theory there is no trouble

driving a v2.

|

|

|

NS Dev

|

| posted on 1/11/06 at 01:11 PM |

|

|

no, two ms setups, one for each engine. they rev to 10500.

Problem is unequal fire, so need pattern trigger wheel or crank and cam sensors (as used by the denso ecu as std)

Retro RWD is the way forward...........automotive fabrication, car restoration, sheetmetal work, engine conversion

retro car restoration and tuning

|

|

|

zilspeed

|

| posted on 1/11/06 at 01:14 PM |

|

|

Mike

I don't think there's any hope whatsoever of running two engines off one ECU .

Just think about startup alone. For it to work then, you would be depending on both engines cranking at the same speed and 'catching' at

the same time. (That's with both cranks having been at the same position when the starter button was hit.)

It's just not going to happen, is it ?

Two ECUs IMveryveryHO

OOPS - This post is redundant - see above

[Edited on 1/11/06 by zilspeed]

|

|

|

MikeR

|

| posted on 1/11/06 at 05:19 PM |

|

|

I was just asking about the 1 ECU as i know NS Dev wants to do it on the cheap & was sure he'd discounted using one ECU in the past - just

wanted to check.

You could theoretically get over the cranking problem by starting the (race) car in gear with the wheels off the ground.

How unequal is the fire ? Just wondering if its something like the same pattern as a couple of cylinders on something like a 6 cylinder?

Just done some reading up, seems the code to run uneven spark was added in experimentally on v2.2 mega squirt n spark extra. Can't find if

anyone actually used it or if its added into later (v3) revisions.

[Edited on 1/11/06 by MikeR]

|

|

|

Syd Bridge

|

| posted on 1/11/06 at 06:28 PM |

|

|

Nat,

That should not be too difficult. MS can be used on V6's, which are mostly 60degreeV.

You just need one cylinder from each bank. Working out which one will be the fun!

Cheers,

Syd.

|

|

|

whittlebeast

|

| posted on 7/11/06 at 11:58 AM |

|

|

Fuel only is not a problem.

The ignition side can be a challange. The trick is to get a clean RPM signal to the squirt and then the number of trigger teeth on the trigger wheel

must be evenly devisable by the number of ignition events per engine cycle. Picture the spark event always sparks at TDC, TDC for each cylinder must

happen as the trigger wheel comes up to a even tooth on the wheel. If you can get the math to come up to this, then these guys can most likely get it

to work. James and Ken are the experts on this at www.msextra.com

AW

|

|

|

NS Dev

|

| posted on 8/11/06 at 03:16 PM |

|

|

there is a 6 tooth trigger (but the docs don't make it clear whether this is the the crank one or the cam one, need to check the manual properly

and maybe so a bit of stripping down and have a look)

so this will be 6 x 60 degrees, and the cyl bank angle is 60 deg too, so that should be ok then.

Retro RWD is the way forward...........automotive fabrication, car restoration, sheetmetal work, engine conversion

retro car restoration and tuning

|

|

|

NS Dev

|

| posted on 8/11/06 at 04:00 PM |

|

|

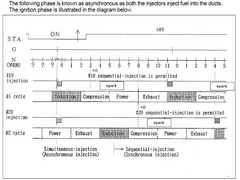

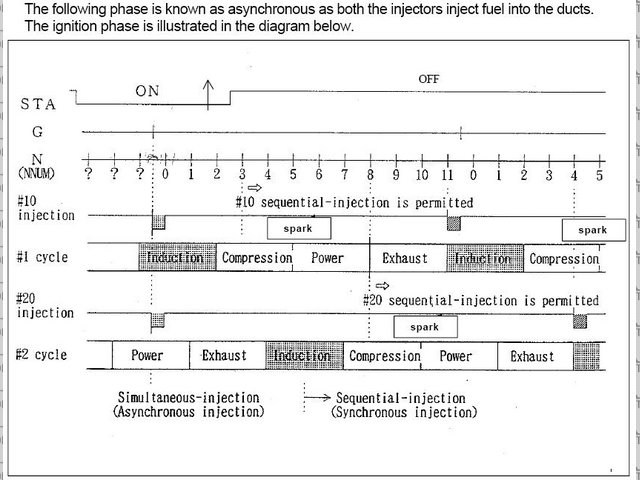

Right, here's a diagram from the RSV Mille tech manual, the titles with it make only limited sense, but from what I can tell it is a diagram of

the sensor outputs vs the engine cycle, on a startup then into running mode.

Seems that (if I read it correctly) that the crank sensor is 6 equal segments (though for some reason counted 0 to 11 (labelled N) , which I guess is

an internal count on the ECU, reset by the cam sensor ) , and the cam sensor is one segment, at TDC on cyl no. 1 (Labelled G)

The actual wording in the manual says that both signals are from the camshaft sensor, and that it sends 1 signal every 720 degrees and 12 per crank

revolution, but then says " i.e. every 60 degrees " which makes no sense at all. I am guessing somewhere they have mixed up crankshaft with

camshaft, which doesn't help!!

If the 12 pulses and the tdc on no. 1 pulse are both from the cam sensor, why bother with the crank one at all????

Firstly, is that how you would read the diagram, and secondly, can that be processed by megasquirt!?

rsv diag 1

[Edited on 8/11/06 by NS Dev]

Retro RWD is the way forward...........automotive fabrication, car restoration, sheetmetal work, engine conversion

retro car restoration and tuning

|

|

|

NS Dev

|

| posted on 9/11/06 at 11:45 AM |

|

|

Right, further investigation yields the following info!!!

The Aprilia engine has 6 pips on the flywheel picked up by the crank sensor, at 60 degree increments, one of which is a very long pip, plus a

(seperate) single pip camshaft sensor, which pulses once every 720 degrees, at around 30 deg btdc on cyl no. 1

can megasquirt use this setup?

[Edited on 9/11/06 by NS Dev]

Retro RWD is the way forward...........automotive fabrication, car restoration, sheetmetal work, engine conversion

retro car restoration and tuning

|

|

|

whittlebeast

|

| posted on 10/11/06 at 11:42 AM |

|

|

I think it can but ask the question over at www.msextra.com

AW

|

|

|