Stuart_B

|

| posted on 8/1/08 at 05:14 PM |

|

|

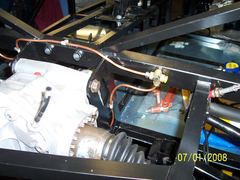

Brake pipes

hi, i done my rear brake pipes and i was wondering would i be allowed for the sva?

Thanks

Stuart

Rescued attachment parts 11157.jpg

|

|

|

|

|

Stuart_B

|

| posted on 8/1/08 at 05:15 PM |

|

|

And this

Stuart

Rescued attachment parts 11156.jpg

|

|

|

Stuart_B

|

| posted on 8/1/08 at 05:16 PM |

|

|

And one more

Stuart

Rescued attachment parts 11155.jpg

|

|

|

matt_claydon

|

| posted on 8/1/08 at 05:32 PM |

|

|

Looks fine to me, as long as the flexis don't rub on the chassis or wishbones.

[Edited on 8/1/08 by matt_claydon]

|

|

|

RazMan

|

| posted on 8/1/08 at 05:33 PM |

|

|

Can't see anything obviously wrong there..... apart from the humungous pics

[Edited on 8-1-08 by RazMan]

Cheers,

Raz

When thinking outside the box doesn't work any more, it's time to build a new box

|

|

|

02GF74

|

| posted on 8/1/08 at 05:33 PM |

|

|

let me guess, Santa brought you a new 10 Mega pixie camera and a utlra wide LCD screen

look ok to me although black P-clips are the fashion for 2008.

NB some SVA centres have been known to fail exposed braid on the hoses - sharp edges would you believe? - to play it safe, wrap some convoluted tubing

over them with cable ties.

|

|

|

matt_claydon

|

| posted on 8/1/08 at 05:34 PM |

|

|

quote:

Originally posted by 02GF74

NB some SVA centres have been known to fail exposed braid on the hoses - sharp edges would you believe? - to play it safe, wrap some convoluted tubing

over them with cable ties.

No rules for sharp edges amongst the rear suspension!

|

|

|

Stuart_B

|

| posted on 8/1/08 at 05:47 PM |

|

|

Sorry about the big picture, thank you for the quick replys.

Thank you

Stuart

|

|

|

indykid

|

| posted on 8/1/08 at 06:02 PM |

|

|

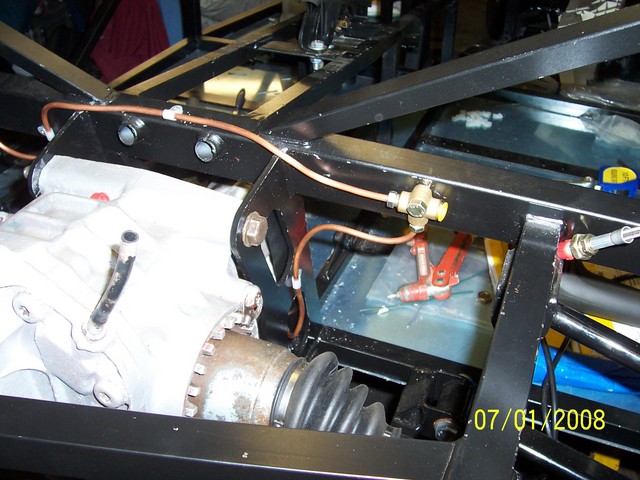

what have you done with the other end of the flexi at the upright/wheel end?

tom

|

|

|

Stuart_B

|

| posted on 8/1/08 at 06:12 PM |

|

|

i have done this

picture below:

Stuart

Rescued attachment parts 11149.jpg

|

|

|

matt_claydon

|

| posted on 8/1/08 at 06:43 PM |

|

|

The hub end needs to be supported where it meets the flexi, else eventually the copper pipe will fatigue and split.

|

|

|

Avoneer

|

| posted on 8/1/08 at 06:45 PM |

|

|

The union in the last pic between flexi and solid needs a solid mouting as well.

Pat...

No trees were killed in the sending of this message.

However a large number of electrons were terribly inconvenienced.

|

|

|

Avoneer

|

| posted on 8/1/08 at 06:45 PM |

|

|

Damn, beaten to a reply again.

Pat...

No trees were killed in the sending of this message.

However a large number of electrons were terribly inconvenienced.

|

|

|

Stuart_B

|

| posted on 8/1/08 at 06:50 PM |

|

|

so i will have to weld a bracket on to the hub, what size steel will i need to use, has any one got any pics of the bracket??

thank you

Stuart

|

|

|

rusty nuts

|

| posted on 8/1/08 at 06:57 PM |

|

|

I made a bracket that is held in place by one of the suspension bolts and made the metal pipe to suit.

|

|

|

David Jenkins

|

| posted on 8/1/08 at 07:17 PM |

|

|

They can fail braided flexy pipes if they're rubbing against other things, like brake pipes, electrics, or similar. The braiding can work like

a file against other surfaces!

|

|

|

John Bonnett

|

| posted on 8/1/08 at 07:42 PM |

|

|

I used small Spirap for wrapping the braided flexibles from Car Builder Solutions and they went through SVA without the tester batting an eyelid.

John

|

|

|

bigbird

|

| posted on 8/1/08 at 08:05 PM |

|

|

my bet is that little yellow bung in the T piece will leak.

|

|

|

Stuart_B

|

| posted on 8/1/08 at 08:57 PM |

|

|

i am have not done the other side yet i need a brake flaring tool, so i can shorten it.

stuart

|

|

|

vinnievector

|

| posted on 9/1/08 at 07:27 AM |

|

|

brake pipes

Picked up two things you might want to look at ,as your pipe gose over the diff support brackets you might get some chaffing their ,also at the wheel

hub end where you have your solid brake pipe from your wheel cylinder to your flexi hose there is no support braket .

attached some picks of my set if it helps

Rescued attachment Picture 219.jpg

|

|

|

tks

|

| posted on 9/1/08 at 06:43 PM |

|

|

also its best to give each side on the T the same lenght!

it wil result in the same pressure losts both rear wheels wil act more the same while unther braking.

Tks

The above comments are always meant to be from the above persons perspective.

|

|

|

RazMan

|

| posted on 9/1/08 at 06:52 PM |

|

|

quote:

Originally posted by tks

also its best to give each side on the T the same lenght!

it wil result in the same pressure losts both rear wheels wil act more the same while unther braking.

It makes no difference whatever length the pipes are - you are still moving the same volume of fluid so the pressure is still the same.

Cheers,

Raz

When thinking outside the box doesn't work any more, it's time to build a new box

|

|

|

NS Dev

|

| posted on 10/1/08 at 11:31 AM |

|

|

two points, already covered but:

1) bracket in 3mm ish steel to support the flexi to copper junction near the drum (weld a bit of 3 mm strip on or hold it with a bolt head)

2) flexi looks like its rubbing the chassis?? If it is it will fail. Just slacken the end fittings and rotate the flexi to a safe position and lock

them up again.

Retro RWD is the way forward...........automotive fabrication, car restoration, sheetmetal work, engine conversion

retro car restoration and tuning

|

|

|

DarrenW

|

| posted on 10/1/08 at 12:11 PM |

|

|

Why cant the flexy be screwed straight into the wheel cylinder?

|

|

|

Stuart_B

|

| posted on 10/1/08 at 02:10 PM |

|

|

so 3mm steel is need for the brackets, and if the flexi is touching the chassis,can i wrap something around the flexi??

Thanks

Stuart

|

|

|