stevebubs

|

| posted on 30/4/08 at 05:10 PM |

|

|

bathroom plumbing

Right,

Finally plumbed dad's new bath in at the weekend (this one fits!!!)

However, the water pressure is absolutely appalling.

Problem 1 - Cold Water Supply

Never great in this room, it would appear that raising the taps by 3inches or so has reduced the cold water flow to the same sort of flow you'd

expect from a watering can.

Now, I'm assuming this lack of water flow is partly due to the lack of height difference between the loft tank and the top of the bath (about

8feet) but my house doesn't have much more than that and the water pressure is fine, so I'm guessing there's other contributing

factors. The feed pipes in both houses are 22mm diameter.

Only 2 things that spring to mind to explain the lack of pressure:

1) There's a restriction in the pipes somewhere (limescale buildup?).

2) The fact the water comes down into the airing cupboard, into the ground floor roof space and across the house before rising up out of the bathroom

floor is a factor.

Any ideas on the cold pressure problem? I would like to maintain the bath off the tank if I can, but it's a reasonably straightforward job to

relocate it to the rising main.

Problem 2 - Hot Water Supply

The pressure for this isn't great, but seems no worse than before. However, I would like to improve it.

Any suggestions? The boiler actually resides at ground level behind the living room fire (old Baxi - Bermuda?, I think)

TIA

Stephen

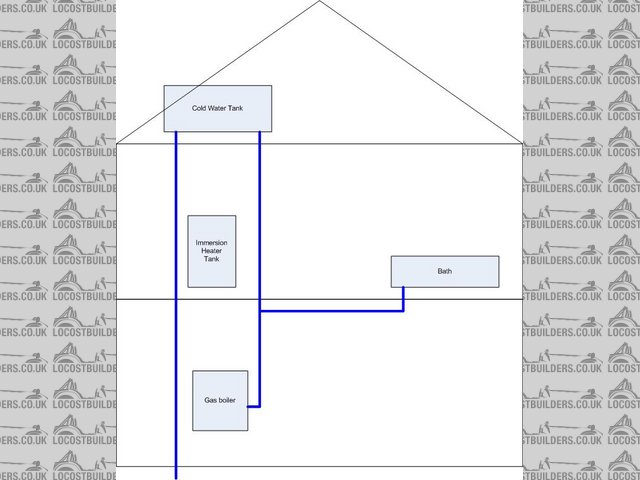

Rescued attachment house.JPG

|

|

|

|

|

MkIndy7

|

| posted on 30/4/08 at 05:20 PM |

|

|

Just a quick one... have U tried putting the old taps back on?

The new taps might be of a different type and more restrictive inside.. espescially as its effecting both hot and cold water, and the hot water was

probably restricted down in the first place.

|

|

|

owelly

|

| posted on 30/4/08 at 05:36 PM |

|

|

If you havn't changed the height of the feed/expansion tank, then the pressure shouldn't have changed. The hot water tank is supplied from

the same header as the cold, the pressures should be the same. It's often the case that hot water tap pressure is a bit lower than that of the

cold because the hot water is cooling as its travelling on it's way to the tap! As both pipes are 22mm, I would say that there is either rubbish

at the bottom of your header tank which you've disturbed and it's blocking the outlet, or as previously mentioned, the taps are for a

higher pressure, with restrictive innards.

http://www.ppcmag.co.uk

|

|

|

stevebubs

|

| posted on 30/4/08 at 05:37 PM |

|

|

quote:

Originally posted by MkIndy7

Just a quick one... have U tried putting the old taps back on?

The new taps might be of a different type and more restrictive inside.. espescially as its effecting both hot and cold water, and the hot water was

probably restricted down in the first place.

did that this evening before I posted as my first reaction was that it may be the taps at fault.

The new tap is definitely a contributing factor. With just a flexi at the tap height, I we can half fill a saucepan from the cold tap in about 15

seconds. With the new taps it takes about 2 minutes.

The hot water on just a flexi half fills said saucepan in about half the time. With the tap installed, it takes about 30 seconds.

Conversely, both the hot and cold taps at my house will fill said saucepan full in about 7 seconds - making the flow rate about twice as high for hot

and 4x as high for cold...

|

|

|

stevebubs

|

| posted on 30/4/08 at 05:37 PM |

|

|

quote:

Originally posted by owelly

If you havn't changed the height of the feed/expansion tank, then the pressure shouldn't have changed. The hot water tank is supplied from

the same header as the cold, the pressures should be the same. It's often the case that hot water tap pressure is a bit lower than that of the

cold because the hot water is cooling as its travelling on it's way to the tap! As both pipes are 22mm, I would say that there is either rubbish

at the bottom of your header tank which you've disturbed and it's blocking the outlet, or as previously mentioned, the taps are for a

higher pressure, with restrictive innards.

With no taps installed, the hot water flexi provides water at twice the rate of the cold....

|

|

|

westf27

|

| posted on 30/4/08 at 05:39 PM |

|

|

modern taps very restrictive unless they are the standard full bore wind up/down.You can fit a double ended pump that works on a pressure drop as you

open the tap.Nice pressurised water flow to all hot taps and low pressure cold fed outlets.

|

|

|

stevebubs

|

| posted on 30/4/08 at 05:42 PM |

|

|

quote:

Originally posted by owelly

The taps are for a higher pressure, with restrictive innards.

I've a suspicion this will be a contributing factor...but not the root of all the problems.

The taps were supplied already fitted to the bath - is there anything we can do to "modify" them to derestrict them?

|

|

|

stevebubs

|

| posted on 30/4/08 at 05:43 PM |

|

|

quote:

Originally posted by westf27

modern taps very restrictive unless they are the standard full bore wind up/down.You can fit a double ended pump that works on a pressure drop as you

open the tap.Nice pressurised water flow to all hot taps and low pressure cold fed outlets.

This sounds like it could be the solution - any suggestions given the house layout above?

|

|

|

billynomates

|

| posted on 30/4/08 at 05:53 PM |

|

|

Fit a combi boiler, if the present boiler is getting old, and your dad has any thoughts that it maye need changing, just get on and do it.

Or maybe modify the current system so it is a pressurised system.

The locost solution - plan your baths well in advance.

|

|

|

Hellfire

|

| posted on 30/4/08 at 05:54 PM |

|

|

I had a similar problem to this when I replumbed my Bathroom...

I found it to be the flexi's that I had used to connect to the taps from the fixed coppers. I hard wired them and the problem was cured.

I used to work in a company that manufactured taps and mixers and restrictions were never a problem. With that head of water you should have no

problems with no pressure. We hardly got any limescale on cold only systems...

If you have any flexi's - replace them or make sure they are not twisted or kinked.

Steve

|

|

|

eccsmk

|

| posted on 30/4/08 at 06:00 PM |

|

|

^^ steve i think you mean hard piped

indeed steve is correct if you've used flexi's they do restrict the flow alot as they are about 6mm core as apposed to copper tails which

are 10 - 15mm bore

hope you manage to get it sorted

|

|

|

stevebubs

|

| posted on 30/4/08 at 06:02 PM |

|

|

quote:

Originally posted by billynomates

Fit a combi boiler, if the present boiler is getting old, and your dad has any thoughts that it maye need changing, just get on and do it.

Not an option, I'm afraid...

quote:

Or maybe modify the current system so it is a pressurised system.

How? Cold is easy to do, but what about the hot....

quote:

The locost solution - plan your baths well in advance.

TBH, if the new taps weren't restrictive to the point where the water literally dribbles out, we probably would have said "sod it"

and he'd had lived with the "not so ideal but workable" pressure available....as has been doing for the last god knows how many

years...

[Edited on 30/4/08 by stevebubs]

|

|

|

stevebubs

|

| posted on 30/4/08 at 06:04 PM |

|

|

quote:

Originally posted by eccsmk

^^ steve i think you mean hard piped

indeed steve is correct if you've used flexi's they do restrict the flow alot as they are about 6mm core as apposed to copper tails which

are 10 - 15mm bore

hope you manage to get it sorted

OK...so next test is to run a copper pipe up to the bath level....

The idea of inserting a pump to up the pressure appeals, though....

|

|

|

tjoh84

|

| posted on 30/4/08 at 06:12 PM |

|

|

the problem can come from 2many compersion fittings as it reduces the flow and traps air.

when i get this prob go in the loft you all ready have a risinf main feeding the tank.

tee off this pipe and disconect cold water feed and plumb to the mains 10 min job

|

|

|

stevebubs

|

| posted on 30/4/08 at 06:17 PM |

|

|

quote:

Originally posted by tjoh84

the problem can come from 2many compersion fittings as it reduces the flow and traps air.

I can't believe 4 is too many? On the code, there is 1 x 22mm isolation valve, 1 x 22mm 90degree fitting, 1 x 22-15mm adapter and 1 x 15mm screw

fitting for the flexi

quote:

when i get this prob go in the loft you all ready have a risinf main feeding the tank.

tee off this pipe and disconect cold water feed and plumb to the mains 10 min job

Ready to go this route for the cold but what about the hot water....?

[Edited on 30/4/08 by stevebubs]

|

|

|

stevepj

|

| posted on 30/4/08 at 06:26 PM |

|

|

to improve pressure on the cold side the easiest thing is to feed everything straight off the rising main, toilet fills faster - may need a restricter

in some cases, cleaning teeth is far nicer with fresh water rather than water from the storage tank full od sediment and the occasional dead thing!

as for the hot, you can increase the flow by increasing the drop from the storage tank into the hot water cylinder, but it will never be massive as

its only using gravity to cause the flow, so scrap the flexi on the hot and use 22mm copper right to the tap

|

|

|

stevebubs

|

| posted on 30/4/08 at 06:29 PM |

|

|

quote:

Originally posted by stevepj

to improve pressure on the cold side the easiest thing is to feed everything straight off the rising main, toilet fills faster - may need a restricter

in some cases, cleaning teeth is far nicer with fresh water rather than water from the storage tank full od sediment and the occasional dead thing!

as for the hot, you can increase the flow by increasing the drop from the storage tank into the hot water cylinder, but it will never be massive as

its only using gravity to cause the flow, so scrap the flexi on the hot and use 22mm copper right to the tap

Increasing the drop isn't going to be possible, and, to be fair, I think the restrictiveness of the tap is still going to be an issue.

The idea of a pump sounds like it might be the right approach....just need to understand what/where/how....

|

|

|

MkIndy7

|

| posted on 30/4/08 at 07:21 PM |

|

|

I'm not sure your drawing is exactly correct.. The Bath water and the Boiler water should NOT be coming from the same tank!.

There should be 2 tanks in the loft, 1 small feed and expansion tank for the boiler and a larger tank that feeds the hot water cylinder and could also

feed the cold water to the bath taps etc.

You CANNOT just connect all the exsiting cold feeds from the tank direct to the mains if it feeds the hot water cylinder. It will not be designed to

take full mains pressure and there would also be no room for expansion of the water when heated (at prescent this should be done by a vent pipe back

upto and over the tank).

As suggested it might be best to remove the flexi's if possible, or maybe get some 22mm ones (so they will have a larger bore), or ask if there

are any "full flow" flexi's at a good plumbers merchants.

Also could any isolation valves on the cold water have snapped in the 1/2 closed position, also cheep ballafix valves can be very restrictive as they

only flow about 8mm and at low pressure this can have a big effect! also has said extra elbows etc.

|

|

|

stevebubs

|

| posted on 30/4/08 at 07:29 PM |

|

|

quote:

Originally posted by MkIndy7

I'm not sure your drawing is exactly correct.. The Bath water and the Boiler water should NOT be coming from the same tank!.

There should be 2 tanks in the loft, 1 small feed and expansion tank for the boiler and a larger tank that feeds the hot water cylinder and could also

feed the cold water to the bath taps etc.

You CANNOT just connect all the exsiting cold feeds from the tank direct to the mains if it feeds the hot water cylinder. It will not be designed to

take full mains pressure and there would also be no room for expansion of the water when heated (at prescent this should be done by a vent pipe back

upto and over the tank).

As suggested it might be best to remove the flexi's if possible, or maybe get some 22mm ones (so they will have a larger bore), or ask if there

are any "full flow" flexi's at a good plumbers merchants.

Also could any isolation valves on the cold water have snapped in the 1/2 closed position, also cheep ballafix valves can be very restrictive as they

only flow about 8mm and at low pressure this can have a big effect! also has said extra elbows etc.

you're quite correct on the 2 header tanks, and the plumbing...

FWIW, the hot pipe also feeds the sink and the pressure is "OK". Not great, but OK.

I'm sure changing the flexis will make a huge difference but not big enough to overcome the bath tap issue...

To repeat what I've implied from previous comments....if it weren't for the restrictiveness of the bath tap, I don't think

we'd have an issue that we'd be bothered out....

So... once the flexis have been replaced with proper copper, the solution would appear to be

1) How to make the tap less restrictive

2) How to increase the pressure/flow to the taps (Pump??)

[Edited on 30/4/08 by stevebubs]

[Edited on 30/4/08 by stevebubs]

|

|

|

MkIndy7

|

| posted on 30/4/08 at 07:41 PM |

|

|

Maybe try and contact the manufacturers of the taps... there might be a restricter in them thats normally used when there on the mains but can be

removed in cases such as yours?.

Or if your really brave take them apart and have a look yourself, there may be part that could be filed away to give more flow or some massive

burr's left from the manufacturing process, you never know!.

There may also be filters on the inlet that you could remove either obvious as you look up the tap or inside somewhere.

|

|

|

stevebubs

|

| posted on 30/4/08 at 07:46 PM |

|

|

quote:

Originally posted by MkIndy7

Maybe try and contact the manufacturers of the taps... there might be a restricter in them thats normally used when there on the mains but can be

removed in cases such as yours?.

Or if your really brave take them apart and have a look yourself, there may be part that could be filed away to give more flow or some massive

burr's left from the manufacturing process, you never know!.

There may also be filters on the inlet that you could remove either obvious as you look up the tap or inside somewhere.

Thanks - another jobs for this weekend!

The idea of also installing a pump really appeals also - not least for the fact that it would enable a decent power shower.

Given the location of the bath wrt the hot water boiler (boiler is on the ground floor at the other end of the house), what options do we have for

this?

|

|

|

ruskino80

|

| posted on 30/4/08 at 07:47 PM |

|

|

there are sometimes filters/aerators on the 'outlet spout' which can be removed to aid better flow-not a lot but a little

for a pump you will need a min of 50 gallons in the cold water storage tank in the loft check that first

pump £100

fittings £10

pipe £10

having a nice shower - priceless

[Edited on 30/4/08 by ruskino80]

|

|

|

stevebubs

|

| posted on 30/4/08 at 07:59 PM |

|

|

quote:

Originally posted by ruskino80

there are sometimes filters/aerators on the 'outlet spout' which can be removed to aid better flow-not a lot but a little

for a pump you will need a min of 50 gallons in the cold water storage tank in the loft check that first

pump £100

fittings £10

pipe £10

having a nice shower - priceless

Tank is definitely big enough....what do I need to have/do for the install?

[Edited on 30/4/08 by stevebubs]

|

|

|

Peteff

|

| posted on 30/4/08 at 08:16 PM |

|

|

Why is your cold tank for the boiler connected to your bath? It shouldn't be and as mentioned earlier your cold to your bath and wash basin

should come from the rising main. Stored water should not be used for tooth brushing only as a head for the hot water. Using it will reduce the volume

in the tank and lower the hot water flow. It can only come out of the hot tank as fast as it is replaced.

[Edited on 30/4/08 by Peteff]

yours, Pete

I went into the RSPCA office the other day. It was so small you could hardly swing a cat in there.

|

|

|

ruskino80

|

| posted on 30/4/08 at 08:16 PM |

|

|

1.drain down tank

2.install 15 mm tank connector low down on side.

3.run 15mm pipe from this to pump(sat on floor next to cylinder)inlet (twin impellor pumps are inlet and outlet per side).

4.cut into 22 mm hot draw off of top of cylinder and t off in 15(or fit an essex flange)fit pipe to other side of pump.

5 pipe up outlets to your new shower valve

6 refill system and run draw offs to expell air

7 plug in pump

that should do it

be carefull though especially around the top of the cylinder part of the job things can go horribly wrong here!!!!

ps this is a very basic description-i shall not be held liable for any disasters!

hth rich

|

|

|