OT: Any NDT (non destructive testing) specialists in the house?

bi22le - 2/7/18 at 06:16 PM

I have a problem at work I'm trying to solve, so thought Ill chuck it on here as I know you lot are as sad as me!

I have a structural foam (ABS blow foam so very porous). We want to NDT a 6mm thick section for voids created from the injection moulding process.

Accuracy is not critical at +/- 0.25mm and we are trying to check that there are no voids with in 2mm of the surface that are more than 2mm in width.

We have access to sensitive ultrasonic flaw detection equipment but it does not work as the porousity prevents sound travel. The NDT needs to be

applied for inline and batch testing so we can't use CT or X-ray scanning.

Anybody know of any other methods?

gremlin1234 - 2/7/18 at 06:47 PM

so I thought I would google

code:

finding the size of holes in swiss cheese

and very strangly got some very practical answers...

this appears to use light.

https://arxiv.org/pdf/1507.06590.pdf

CMB seen through random Swiss Cheese

for cmb see

https://en.wikipedia.org/wiki/Cosmic_microwave_background

does this count as thinking outside the box? or just weird?

[Edited on 2/7/18 by gremlin1234]

bart - 2/7/18 at 09:54 PM

Acoustic tapping with results reported on ociloscope.

Just a guess but woth a think

ttalps2000 - 3/7/18 at 08:43 PM

weight the sample against a known good sample? Thats how they verify a lot in plastic injection molding.

Have done Xray scanning before, but you dont get decent results really.

bart - 3/7/18 at 09:57 PM

ive had another thought

add something to the mix to make it more seeable to various test methods. ie maybe iron powder , or stainless powder

02GF74 - 4/7/18 at 05:29 PM

quote:

Originally posted by bi22le

). We want to NDT a 6mm thick section for voids created from the injection moulding process.

we are trying to check that there are no voids with in 2mm of the surface that are more than 2mm in width.

To see that I understand, you want to test a 6mm thick section of unspecified length

No voids of 2mm, does that exclude two or more 1mm voids very close together.

What is the budget for the test equipment, Insttallion. Commissioning and time scales.

Is the testing done on each item or a limited number of samples from a batch.

bi22le - 4/7/18 at 10:44 PM

quote:

Originally posted by bart

Acoustic tapping with results reported on ociloscope.

Just a guess but woth a think

This is a tough one to rely on, which I need to, without 6 months of research. I have a week!!

Thanks for your input.

bi22le - 4/7/18 at 10:47 PM

This was a great shout and one I spent a morning playing with. We have some super bright boroscopes and the theory worked. I managed to identify an

area with a void.

My team were not keen though as we had to drill a hole to gain access below the very dense plastic near the surface. It needs to be NDT so was

canned.

Great input though. Thanks.

quote:

Originally posted by gremlin1234

so I thought I would google

code:

finding the size of holes in swiss cheese

and very strangly got some very practical answers...

this appears to use light.

https://arxiv.org/pdf/1507.06590.pdf

CMB seen through random Swiss Cheese

for cmb see

https://en.wikipedia.org/wiki/Cosmic_microwave_background

does this count as thinking outside the box? or just weird?

[Edited on 2/7/18 by gremlin1234]

bi22le - 4/7/18 at 10:49 PM

The parts in question weight approx 3.5kg. with holes all over it, there is no way we would get good data.

Thanks for the input though. We did discuss weighing it.

quote:

Originally posted by ttalps2000

weight the sample against a known good sample? Thats how they verify a lot in plastic injection molding.

Have done Xray scanning before, but you dont get decent results really.

bi22le - 4/7/18 at 10:51 PM

This could of been a possibly but we have already had these made and it is a medical device so we are heavily restricted on materials that we can

use.

quote:

Originally posted by bart

ive had another thought

add something to the mix to make it more seeable to various test methods. ie maybe iron powder , or stainless powder

bi22le - 4/7/18 at 10:55 PM

quote:

Originally posted by 02GF74

quote:

Originally posted by bi22le

). We want to NDT a 6mm thick section for voids created from the injection moulding process.

we are trying to check that there are no voids with in 2mm of the surface that are more than 2mm in width.

To see that I understand, you want to test a 6mm thick section of unspecified length. CORRECT

No voids of 2mm, does that exclude two or more 1mm voids very close together. IDEALLY DETECT LARGE VOIDS ONLY AND NOT MULTIPLE SMALLER VOIDS.

What is the budget for the test equipment, Insttallion. Commissioning and time scales. LARGE BUDGET, LITTLE TIME,

Is the testing done on each item or a limited number of samples from a batch. INITIAL BATCH TEST OF 80 BUT THEN USED IN OQ IQ PQ VALIDATION FOR AROUND

180 PARTS. DEPENDING ON SOLUTION CONTINUED FIRST OF, LAST OFF

HowardB - 5/7/18 at 06:44 AM

have you approached the foam manufacturer? Quite often they have extensive research departments,... I used to use 3M and also OMI foam research teams

in my previous jobs,

hth

bi22le - 5/7/18 at 11:55 AM

quote:

Originally posted by HowardB

have you approached the foam manufacturer? Quite often they have extensive research departments,... I used to use 3M and also OMI foam research teams

in my previous jobs,

hth

I wish!

It is due to the lack of their process and quality control we having these problems. They are trying to avoid responsibility altogether even though it

is quite obviously a process problem.

02GF74 - 5/7/18 at 05:24 PM

quote:

Originally posted by bi22le

quote:

Originally posted by 02GF74

No voids of 2mm, does that exclude two or more 1mm voids very close together. IDEALLY DETECT LARGE VOIDS ONLY AND NOT MULTIPLE SMALLER VOIDS.

What is the budget for the test equipment, Insttallion. Commissioning and time scales. LARGE BUDGET, LITTLE TIME,

Is the testing done on each item or a limited number of samples from a batch. INITIAL BATCH TEST OF 80 BUT THEN USED IN OQ IQ PQ VALIDATION FOR AROUND

180 PARTS. DEPENDING ON SOLUTION CONTINUED FIRST OF, LAST OFF

Don't quite understand why multiple small voids are not a concern as they may be weaker than one large one, but no matter.

Large budget means what, 500 or 5 million? A pointless reply to arguably pointless question, I was trying to gauge whether you a working for a multi

million company on an industrial estate in Slough or for Barry in a lock up in Daventry and would have geared my response accordingly.

Anyway let's not get bogged down in this but here are some ideas, may not solve the problem but may help towards solving it.

.

Electromagnetic radiation, uv, ir, visible, x Ray would be my first

call, how transparent is the foam. This would show depth of total voids but not size or if there is more than one. That could be done by swivelling

the beam with some clever software.

.next would be electrical property, either resistance or capacitance. A series of probes on opposite sides could do meadument and again clever

software to figure it out. .

Mechanical, measure the force required to push small probes into the foam, assuming it is elastic.

Sound, the foam will absorb sound that would pass largely unhindered by the air/gas in the voids.

The above may be BS so.

1. Contact foam manufacturer or users of foam to see how they measure it, maybe you have friends in the same industry.

2. Contact manufacturers of test equipment.

3. Contact the institute of physics, chemistry for ideas.

4. Contact University material science depts.

5. Contact manufacturers of airport x Ray scanning equipment.

My gut feeling is that if there is something available or needs to be made bespoke, the cost will be in the 10s if not 100s of thousands.

Good luck, let us know know how you solve is.

HowardB - 5/7/18 at 08:33 PM

perhaps Electromagnetics in GHz region might work, there are very specific absorption frequencies for different materials and even different

molecules, water, Nitrogen etc, so perhaps a larger void will show up if the foam is moisture blown?

I have used ultrasonics to detect voids in a solid polymer, but have no experience about how it might detect large voids amongst many smaller ones,

perhaps specific algorithms could be used to find the larger voids,...

certainly sounds like fun,...

bi22le - 5/7/18 at 10:13 PM

The reason I want to stay clear from multiple small voids as they are a by product of the process. Gas filled injection molding creates voids but they

should not be the size of some that we are experiencing, which are 3 or 4 times the size as process acceptable voids. The resulting weakness in the

structure is substantial. Think honey comb vs large voids, which is stronger?

Large budge is perceptual, hence my vague response. I work for a multi billion pound global medical company. . . . .

X-ray, CT and several others have been discussed but this is for process validation and therefore we may need to test hundreds of parts, and fast.

most of these take days to return 1 result and would be to a far greater resolution than we require. We need a go no go failure method.

Capacitance was considered but we need to not be inventing a new NDT technique to solve this problem, it needs to be off the shelf. Something that is

pretty cut and shut that gives us simple answers without a PhD in multiple disciplines.

Displacement of walls relating to force applied is an interesting thought. Sound does not work. We have some very good ultrasonic NDT technology and

there is too much air attenuating the sound.

Thanks for your input. I will detail progress below.

quote:

Originally posted by 02GF74

quote:

Originally posted by bi22le

quote:

Originally posted by 02GF74

No voids of 2mm, does that exclude two or more 1mm voids very close together. IDEALLY DETECT LARGE VOIDS ONLY AND NOT MULTIPLE SMALLER VOIDS.

What is the budget for the test equipment, Insttallion. Commissioning and time scales. LARGE BUDGET, LITTLE TIME,

Is the testing done on each item or a limited number of samples from a batch. INITIAL BATCH TEST OF 80 BUT THEN USED IN OQ IQ PQ VALIDATION FOR AROUND

180 PARTS. DEPENDING ON SOLUTION CONTINUED FIRST OF, LAST OFF

Don't quite understand why multiple small voids are not a concern as they may be weaker than one large one, but no matter.

Large budget means what, 500 or 5 million? A pointless reply to arguably pointless question, I was trying to gauge whether you a working for a multi

million company on an industrial estate in Slough or for Barry in a lock up in Daventry and would have geared my response accordingly.

Anyway let's not get bogged down in this but here are some ideas, may not solve the problem but may help towards solving it.

.

Electromagnetic radiation, uv, ir, visible, x Ray would be my first

call, how transparent is the foam. This would show depth of total voids but not size or if there is more than one. That could be done by swivelling

the beam with some clever software.

.next would be electrical property, either resistance or capacitance. A series of probes on opposite sides could do meadument and again clever

software to figure it out. .

Mechanical, measure the force required to push small probes into the foam, assuming it is elastic.

Sound, the foam will absorb sound that would pass largely unhindered by the air/gas in the voids.

The above may be BS so.

1. Contact foam manufacturer or users of foam to see how they measure it, maybe you have friends in the same industry.

2. Contact manufacturers of test equipment.

3. Contact the institute of physics, chemistry for ideas.

4. Contact University material science depts.

5. Contact manufacturers of airport x Ray scanning equipment.

My gut feeling is that if there is something available or needs to be made bespoke, the cost will be in the 10s if not 100s of thousands.

Good luck, let us know know how you solve is.

bi22le - 5/7/18 at 10:15 PM

I think the foam is gas blown, but either way it is a process failure causing the issue. Probably due to poor venting in the IM tool.

quote:

Originally posted by HowardB

perhaps Electromagnetics in GHz region might work, there are very specific absorption frequencies for different materials and even different

molecules, water, Nitrogen etc, so perhaps a larger void will show up if the foam is moisture blown?

I have used ultrasonics to detect voids in a solid polymer, but have no experience about how it might detect large voids amongst many smaller ones,

perhaps specific algorithms could be used to find the larger voids,...

certainly sounds like fun,...

bi22le - 5/7/18 at 10:20 PM

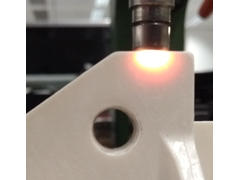

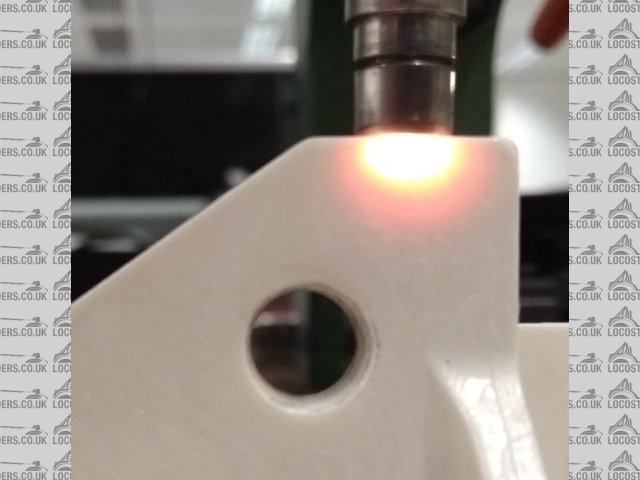

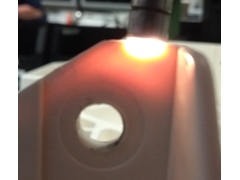

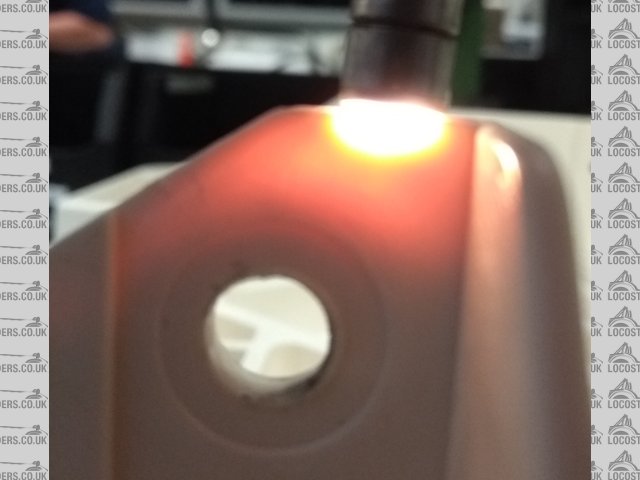

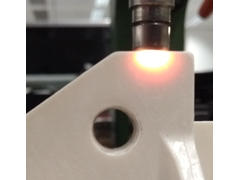

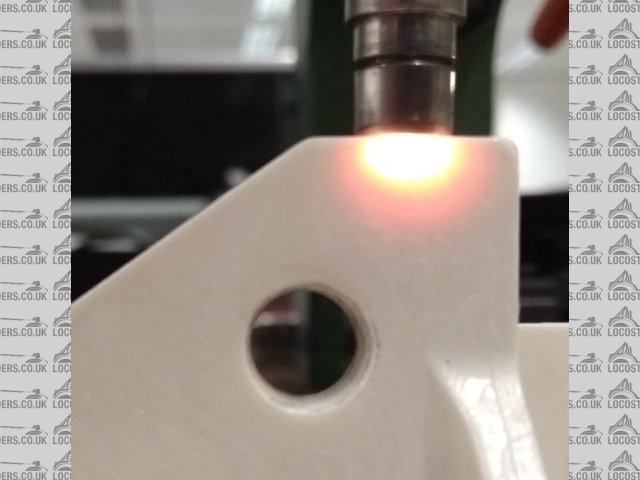

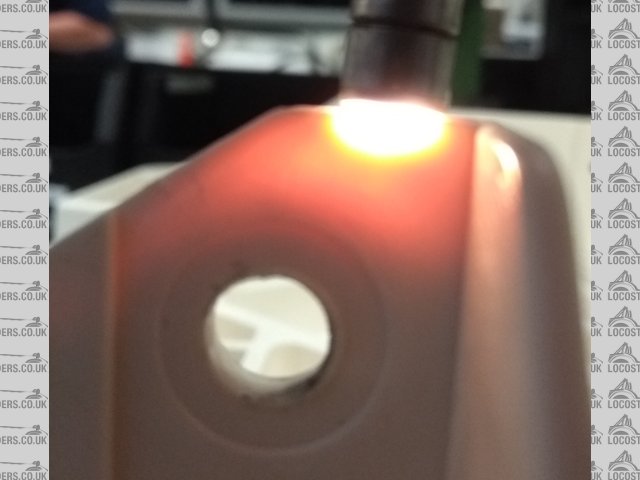

So, someone mentioned using light.

I have access to some very bright and configurable light sources.

This an example of a good area. Note how far the light penetrates and its regular shape:

good side

This a bad side. See how the light penetrates deeper due to a void and how you can even see a void travelling down at an angle. Neat right?!?!?:

bad side

This is my current path of investigation. Tomorrow I am going to spend a day pointing light at plastic and trying to characterise void volumes, shapes

and proximity to the surface. Yes this is fun, yes I am sad!!!

HowardB - 5/7/18 at 10:24 PM

that seems fair, I guess that it is a matter of which bit of the spectrum that you use and what is used to detect it,. I have been having some fun

playing with thermal imaging kit recently, perhaps the IR end of the spectrum can be used to see how heat is transmitted or how the part warms or

cools,. the air pockets changing temp differently to the blown foam,...?