some time ago I fitte a new pair of DIY ported SD1 heads to a P6 block, new timing gear, new 3.9 cam and followers to my 3.6l v8.

Also use the second blanked off port on the inled manifold to feed a vacuum guage but the reading on the guage it too low i.e. there should be more

vacuum (twin HIF6 carbs with K&N cone filters).

I would like to rule out there is no air leak - any ideas on how to find one, if there is one?

Inlet manifold and carbs are on tight - checked and retightened so unlikley but .....

The 3.9 and 3,5 cams don't differ that much so I doubt that would account for it nor do I thhk the matching of ports in the head will either.

Are there any other sumptoms such as misfire (none) that accompany inlet leaks?

I am assuming the guage is reading correctly - the needle does move in the

right direction.

Connect a compressor to the vacuum port, block off the butterflies and pressurise the inlet side??

quote:

Originally posted by stevebubs

Connect a compressor to the vacuum port, block off the butterflies and pressurise the inlet side??

I've fitted vac and turbo gauges to cars in the past.

I've always used the provided t-piece into the vacuum tubing as it has a restrictor built in to it. Otherwise the gauges under read.

quote:

Originally posted by chockymonster

I've fitted vac and turbo gauges to cars in the past.

I've always used the provided t-piece into the vacuum tubing as it has a restrictor built in to it. Otherwise the gauges under read.

....athough I am pretty sure reading on the web that what I have done is correct, hmm....

....athough I am pretty sure reading on the web that what I have done is correct, hmm....

can of brake cleaner and spray it around the carb and manifold if it leaks the engine will try to stall ,check the carbs are synchronised as one

further open than the other with twin su,s will lose your manifold vacuum giving you the low reading

You will only get a low reading with the vacuum gauge connected to just one inlet port. Try teeing off from your brake servo hose , that will give an even reading from all cylinders. Also when checking for air leaks spray WD 40 around suspect areas and listen to engine. Revs will pick up if an air leak is found .

quote:

Originally posted by chockymonster

I've always used the provided t-piece into the vacuum tubing as it has a restrictor built in to it. Otherwise the gauges under read.

I've always used HKS gauges on my previous jap tintops. The HKS gauge is supplied with a restrictor in the line, either in the t-piece or at the

connecting pipe on the gauge.

If you fit the gauges without the restrictor then the gauge didn't read correctly.

When I replaced the OE boost gauge on my evo I couldn't understand how I'd just dropped from 1.6bar to 1 bar. Swapped the t-piece over and

it worked perfectly

That makes no sense at all.

As long as the size of the entry to the sender (which is an internal component in this case) doesn't alter, which it doesn't even if you go

up to massive pipe it still ends up at the same size on the sender itself, then the pressure will always read the same and be correct.

12mm vacuum hose going to a 1mm vacuum hose will read the same pressure as using a 1mm hose throughout with the same input pressure.

Can't understand for a second how your Evo did what it did unless you physically enlarged the pipe entry to the sender itself, which you

didn', or if you did then it will now be reading incorrectly.

The only thing which would make sense, is that if it used to show 0bar on the OE gauge at idle. Where in actual fact it should show some vacuum

(possibly 0.6 bar!) depending on various factors. It certainly shouldn't have shown 0 bar as they'll always be a negative pressure at

idle/overrun as the engine sucks in air.

If you plumb in an accurate vacuum/boost gauge anywhere on the inlet manifold, you'll get a proper, accurate vacuum/boost reading irrespective of

pipe size.

I ran a vac guage on my Rangie with a 3,9 cam in a 3.5 engine. I took my feed off the feed for the air intake valve, the reading was always lower than

it says in the book, I think these engines just run a low inlet vacuum. main thing to watch for is variations or needle flutter. Once you know what

the engine normally pulls just make sure it doesn't drop or fluctuate under different conditions.

Caber

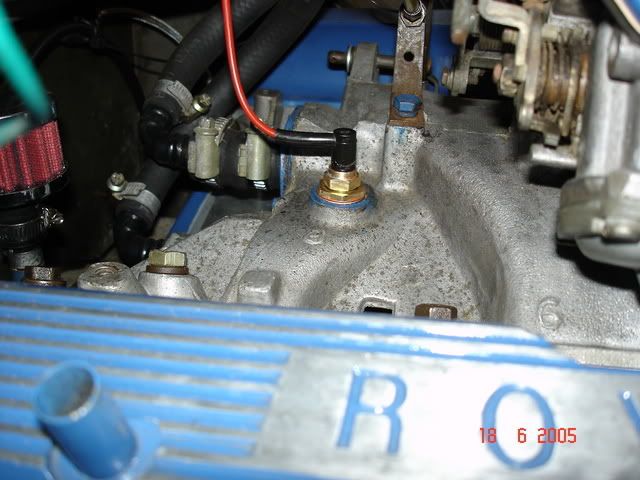

The Smiths vac gauge is supplied with a restrictor, to prevent erratic fluctuations in the readings. It is a small brass plug with a small hole

through it, similar to a mig welding tip. It is fitted in the pipe at the manifold end. It is not always needed, but is usually fitted when the

distance between the gauge and manifold is short. The actual pipe is also quite a small bore, about 3mm.

Most vac gauges are designed to work with a small bore tube, the restrictor making it even smaller where necessary, using a larger tube results in

false readings

Cheers John

[Edited on 28/6/06 by johnjulie]

quote:

Originally posted by caber

I ran a vac guage on my Rangie with a 3,9 cam in a 3.5 engine. I took my feed off the feed for the air intake valve, the reading was always lower than it says in the book, I think these engines just run a low inlet vacuum. main thing to watch for is variations or needle flutter. Once you know what the engine normally pulls just make sure it doesn't drop or fluctuate under different conditions.