Home made exhaust

paulbeyer - 28/3/07 at 05:45 AM

Without having to trawl through everyones picture archives does anyone have any pictures of an exhaust made from s/s dairy bends they could point me

at? Especially a 4 into 1 system. I don't know how to create the 4 pipe collector.

Fred W B - 28/3/07 at 05:59 AM

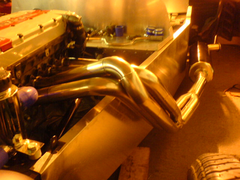

exhaust

Collector is a piece of 3 inch pipe forced into a sqare shape with rounded edges by pressing 4 bits of steel bar of the approx header dia welded

together into one end, and a fabricated 3 to 2 inch cone on the other by cutting wedges out the pipe, bending closed and welding up.

The welded up 4 bar former obviously has to have the end tapered to fit into the pipe

Don't forget to weld a star plate between the 4 pipes before you put the collecter on

Cheers

Fred W B

[Edited on 28/3/07 by Fred W B]

Mr Whippy - 28/3/07 at 07:12 AM

nice job

[Edited on 28/3/07 by Mr Whippy]

Hellfire - 28/3/07 at 08:35 AM

Lovely bit of piping....

Steve

smart51 - 28/3/07 at 08:45 AM

http://www.locostparts.net/index.php?cPath=21&osCsid=814bka9qc9ek9pvu290auml7j4

look at these self assembly exhausts.

MikeR - 28/3/07 at 09:50 AM

look up NS Dev and exhaust.

he's made a lovely system and made a 4-1 collector.

NS Dev - 28/3/07 at 10:28 AM

exhaust 4

paulbeyer - 28/3/07 at 11:08 AM

quote:

Originally posted by MikeR

look up NS Dev and exhaust.

he's made a lovely system and made a 4-1 collector.

It's hard to tell from that angle but isn't NS Dev's exhaust a 4-2-1? NS, Fred thats amazing work on both parts. Would you be able to

form a collector like yours Fred if it was made from s/s?

Thanks for the info gents.

Fred W B - 28/3/07 at 11:35 AM

Thanks for the kind words guys.

The "classic" way to do a 4 branch collector is as NS dev has done, but with 4 bends cut and tigged together.

Mine is not as neat, but it gets the job done and means buying 4 less bends.

As for fabricating in stainless, steel is steel, in fact ss may form better as it is more ductile than carbon steel - which my pipes are.

If you don't have a 3" pipe and a suitable press and former, you would have to fabricate from sheet.

email me if you would like some more detail on how I made the manifolds

Cheers

Fred W B

[Edited on 28/3/07 by Fred W B]

ayoungman - 28/3/07 at 12:18 PM

weve certainly got some talented fellas on this site haven't we.?

Switch to green with envy mode !

NS Dev - 28/3/07 at 12:22 PM

quote:

Originally posted by paulbeyer

quote:

Originally posted by MikeR

look up NS Dev and exhaust.

he's made a lovely system and made a 4-1 collector.

It's hard to tell from that angle but isn't NS Dev's exhaust a 4-2-1? NS, Fred thats amazing work on both parts. Would you be able to

form a collector like yours Fred if it was made from s/s?

Thanks for the info gents.

yeah, 4-2-1 but it shows the collectors, made as fred suggested, and the same works for 4-1, you just make two slash cuts in the collector bends, at

90 degrees to each other, and weld them all together.

liam.mccaffrey - 28/3/07 at 02:45 PM

http://www.locostbuilders.co.uk/viewthread.php?tid=41221

link to thread where i asked questions about collector fabbing

TangoMan - 28/3/07 at 03:00 PM

I haven't got any pictures but I made my collector by shaving down four lengths of pipe (same as primaries) progressively from one end to the

other and them welded them together to form a funnel. I works OK but was a bit time consuming.

If that doesn't make sense, One end was around 270degrees left on the pipe while the narrow end, sized to fit the main pipe, was around 100

degrees of pipe.

I would draw a picture but I ned to get back to work.

Steve

paulbeyer - 28/3/07 at 03:26 PM

Excellent info and pictures, thanks. What do you recommend for cutting the pipe work accurately? I can imagine that it would be easy to screw up a

join if you dont get the cuts sorted out properly. I was thinking angle grinder with a thin cutting disk but I can see that wandering too much.

Simon - 28/3/07 at 07:10 PM

ATB

Simon

JoelP - 28/3/07 at 07:48 PM

a 0.8mm disc in a grinder can be remarkably accurate. I use one at work to cut extractor chinmeys to length. Its quite easy.

MikeRJ - 29/3/07 at 07:25 AM

I found an air powered hacksaw to be excellent for cutting thin wall tube such as exhausts. The stroke is very small so it doesn't tend to snag

on the edges of the material as a hand hacksaw would.

e.g. one like this.

[Edited on 29/3/07 by MikeRJ]

NS Dev - 29/3/07 at 03:00 PM

I would say it would be impossible to have made my manifold without a belt linisher.

They are cheap enough now, the ones with a 4" wide belt and a disc sander on the side. You can square the ends with the table on the disc sander

and debur and profile using the belt, plus re-angle ends until you have no gap before welding.

To give you some idea of how good the fits need to be......I used about 3" of filler rod on that manifold, all the rest was done without filler

(Autogenous welding I think its called), apart from the head flange to pipe welds.

paulbeyer - 29/3/07 at 07:53 PM

quote:

Originally posted by NS Dev

I would say it would be impossible to have made my manifold without a belt linisher.

They are cheap enough now, the ones with a 4" wide belt and a disc sander on the side. You can square the ends with the table on the disc sander

and debur and profile using the belt, plus re-angle ends until you have no gap before welding.

Hi Mate do you mean this sort of thing?

Ebay

linky

If so any recommendations as I was about to buy a standard bench grinder anyway.

Just noticed that was a 2" width belt. Probably to0 small.

[Edited on 29/3/2007 by paulbeyer]

[Edited on 29/3/2007 by paulbeyer]

timf - 30/3/07 at 08:00 AM

this one i think

paulbeyer - 30/3/07 at 10:50 AM

Mmmmm, looks nice (read expensive). Do you know make and model?

PeterW - 30/3/07 at 11:00 AM

Looks like an Axminster one

Here

Cheers

Pete

paulbeyer - 30/3/07 at 11:04 AM

Cheers for the quick response Pete. Tis deffo an axminster. Price is not too shabby either. Are Axminster tools any good? Must admit I've never

heard of them before.

MikeRJ - 30/3/07 at 11:30 AM

quote:

Originally posted by paulbeyer

Cheers for the quick response Pete. Tis deffo an axminster. Price is not too shabby either. Are Axminster tools any good? Must admit I've never

heard of them before.

Quite a well known company IMO, they have a good reputation for customer service. The lower priced lathes and mills they sell tend to be the better

quality chinese products, I suspect that probably applies to the unbranded power tools as well.