02GF74

|

| posted on 16/2/06 at 11:14 AM |

|

|

DIY static engine balancing

Let's say you have a modern engine, 1990, from Vauxhall or Ford.

Would there be any benefit in balancing the reciprocating parts (con-rods + pistons + rings + big end bolts) yourself or are they ok from the

factory?

Method would be to put each on digital kitchen scales, weigh and compare.

Where would be the best place to remove metal from?

And is there any way dynamic balancing can be done DIY style?

|

|

|

|

|

BKLOCO

|

| posted on 16/2/06 at 11:51 AM |

|

|

My first comment would be that kitchen scales would be nothing like accurate enough to balance an engine.

Experience is what you get when you don't get what you want!!!

|

|

|

Lippoman

|

| posted on 16/2/06 at 11:53 AM |

|

|

Factory balancing is usually OK if you do not intend to increase the redline or run it at the redline for long times. For some engines (Rover

K-series) the factory balancing is better than many aftermarket speed shops.

Lightening parts should not be done if not balancing dynamically afterwards.

Conrods should be weighed each end (big end/piston end). The ends are also usually the best place to remove material.

Usually, balancing and dyno work are the most efficiently spent money if seriously tuning an engine, in regard to power, driveability and endurance.

I've seen many engines where the expected power and torque range were not reached due to not taking the time and cost of dyno, and others where

endurance problems were encountered due to not balancing.

[Edited on 16/2/06 by Lippoman]

|

|

|

NS Dev

|

| posted on 16/2/06 at 12:02 PM |

|

|

Kitchen scales accurate to 1 gramme (which a lot of decent digital ones are) will be fine for balancing.

As for actually doing the job, look on John Beardmore's site for inspiration (he posts on here as JB)

www.beardmorebros.co.uk

Retro RWD is the way forward...........automotive fabrication, car restoration, sheetmetal work, engine conversion

retro car restoration and tuning

|

|

|

bernie955

|

| posted on 16/2/06 at 12:05 PM |

|

|

You don't want to balance the rings and rod bolts. You can balance the pistons with rings fitted if you wanted but most weight differences will

be with pistons and rods mostly. Also, rods are usually balanced from end to end i.e. big end and small end are done separately. Rods usually have

pads at top and bottom you can remove material from (I have experience with Chevy V8s) and pistons can have material removed from areas inside the

skirts. These days piston sets should be pretty close with modern manufacturing techniques.

Crank is normally balanced as well but you can't really do that at home. Weights are added to cover piston/rod weight and the crank is spun to

identify where it is out of balance.

You'd also need to have fairly accurate scales to do it properly. Even 1 gram spinning at 6500 rpm can be applying Kgs of out-of-balance weight.

|

|

|

bernie955

|

| posted on 16/2/06 at 12:08 PM |

|

|

I forgot to mention you should balance the rods with rod bolts included. It's dangerous to remove material from the bolts (weakens them) or any

areas other than previously mentioned. Removing casting flash from rods can reduce the possibility of cracks forming as well as these are areas where

stress can be concentrated.

|

|

|

mark chandler

|

| posted on 16/2/06 at 12:31 PM |

|

|

I cannot see why you need accurate scales as this is a comparison between lumps of metal. If the scale reads 20 grams out so what, each piston will

apear 20 grams heavier than it is !

Surely all you are looking to do is make all the pistons and rods the same weight, you could do this with a simple balance.

It would not hurt to do this.

For a 4 cylinder engine with you can balance the crank, clutch and front pulley with a pair of knife edges on the at each end, not as good as a

dynamic balance as you will not know how far along the crank to strip the weight but fine for the lumps of metal at both ends.

But then you will probally be mor dillegent than a machine operator so should get an equivilent result.

Regards Mark

|

|

|

bernie955

|

| posted on 16/2/06 at 12:41 PM |

|

|

I meant that the scales should be able to measure fairly small increments, not be accurately reporting actual weights. Static balance should be pretty

easy to obtain but rotating balance I'd leave to the experts.

|

|

|

britishtrident

|

| posted on 16/2/06 at 12:42 PM |

|

|

Repeatability is an issue with kitchen scales --- Maplin have some nice scales on special this month -- and other nice gear too including a very nice

Multimeter with PC connection.

|

|

|

02GF74

|

| posted on 16/2/06 at 02:43 PM |

|

|

quote:

Originally posted by mark chandler

For a 4 cylinder engine with you can balance the crank, clutch and front pulley with a pair of knife edges on the at each end, not as good as a

dynamic balance as you will not know how far along the crank to strip the weight but fine for the lumps of metal at both ends.

can't quite picture this - can you expalin a bit more about the placement of the knife edges (you forgot the flywheel in there!  ) )

|

|

|

JB

|

| posted on 16/2/06 at 06:46 PM |

|

|

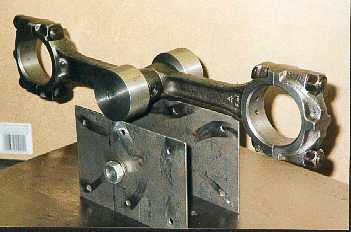

Balancing

As Mr NSDev has mentioned it is quite easy to balance your own rods and pistons.

Balance is the word, you do not weigh them but balance them. This page shows the basic idea.

http://www.beardmorebros.co.uk/website%20pages/new_project_engine_page1.htm

If you use this method check for repeatability. Try to balance the rods with washers on the end. Then dismantle everything , reassmemble, reposition

etc and see if you get the same result. If you can not get good repeatability then do not try it yourself.

John

|

|

|

BKLOCO

|

| posted on 16/2/06 at 06:57 PM |

|

|

quote:

Originally posted by NS Dev

Kitchen scales accurate to 1 gramme (which a lot of decent digital ones are) will be fine for balancing.

Bull

They may read to 1 gram but that does NOT make then accurate to 1 gram

Experience is what you get when you don't get what you want!!!

|

|

|

Cousin Cleotis

|

| posted on 16/2/06 at 07:40 PM |

|

|

all inline fours will vibrate without a balance shaft. a few grams out of balance will only make a few kilograms of force at high engine speeds,

nothing compared to the few tonnes of force created during combustion. is it really worth it?

Paul

|

|

|

britishtrident

|

| posted on 16/2/06 at 08:16 PM |

|

|

quote:

Originally posted by Cousin Cleotis

all inline fours will vibrate without a balance shaft. a few grams out of balance will only make a few kilograms of force at high engine speeds,

nothing compared to the few tonnes of force created during combustion. is it really worth it?

Paul

Having seen engines explode at 10000 RPM because the flywheel was swapped for one not balanced to that particular crank I would disagree.

|

|

|

gazza285

|

| posted on 16/2/06 at 08:49 PM |

|

|

Granted, but only an idiot or somebody going all out and bugger the costs would build an engine to rev to 10,000rpm and not use balanced

components.

I would be surprised if DIY balancing on a modern engine would improve things past the factory tolerances, but I can see the point on JB's

Seventies/Eighties hybrid Fiat engine, as I could see the point of having my own engine (Crossflow)dynamically balanced

DO NOT PUT ON KNOB OR BOLLOCKS!

|

|

|

Cousin Cleotis

|

| posted on 17/2/06 at 01:34 PM |

|

|

would somebody thinking about DIY balancing also be building an engine to rev to 10,000rpm? i doubt it.

Paul

|

|

|

MikeRJ

|

| posted on 17/2/06 at 04:15 PM |

|

|

quote:

Originally posted by Cousin Cleotis

all inline fours will vibrate without a balance shaft. a few grams out of balance will only make a few kilograms of force at high engine speeds,

nothing compared to the few tonnes of force created during combustion. is it really worth it?

Paul

Once the frequency of the out of balance forces hits the cranks resonant frequency, amplitude gets out of hand quite quickly. This is why crank

dampers are so important, and why aftermarket billet alloy crank pulleys that replace them are such a bad idea.

|

|

|

Cousin Cleotis

|

| posted on 17/2/06 at 06:07 PM |

|

|

i understand resonant frequencies, but a inline 4 without a balance shaft(or two?) will always vibrate no matter how well they are balanced, so could

still match the resonant frequency of the crank.

Paul

|

|

|

britishtrident

|

| posted on 17/2/06 at 09:42 PM |

|

|

quote:

Originally posted by Cousin Cleotis

i understand resonant frequencies, but a inline 4 without a balance shaft(or two?) will always vibrate no matter how well they are balanced, so could

still match the resonant frequency of the crank.

Paul

All engines vibrate an inline 4 isn't bad as long as moving parts are kept light, it is a lot better than most engines.

Balancing shafts don't stop the vibration but only cancel out the external motion of the engine block.

A good four without balancing shaft is smoother than some fours with --- the 2 litre Rover T16 engine without balancing shafts was considerably

smoother than Hondas big four that Rover used in the 600 series which had twin balancing shafts.

Prize for the roughest straight 4 goes to Vauxhalls awful 60s/70s slant four Victor engine which tried hard to bounce its way out the engine bay.

A good straight six may be silky sweet at low rpm but at higher crank suffer from torsional vibrations due the long crankshaft.

This is why straight sixes always have massive torsional vibration dampers on the front end of the engine.

All Vee engines have rocking couples -- V12s are sweet enough but a V4 or V6 just should never be made while a V8 is really no better than 2

straight fours,

|

|

|

gazza285

|

| posted on 18/2/06 at 03:01 AM |

|

|

quote:

Originally posted by britishtrident

the 2 litre Rover T16 engine without balancing shafts was considerably smoother than Hondas big four that Rover used in the 600 series which had twin

balancing shafts.

Just a shame it pissed oil out, otherwise a reliable enough lump, one of Rovers better efforts.

DO NOT PUT ON KNOB OR BOLLOCKS!

|

|

|

02GF74

|

| posted on 18/2/06 at 10:08 AM |

|

|

quote:

Originally posted by BKLOCO

quote:

Originally posted by NS Dev

Kitchen scales accurate to 1 gramme (which a lot of decent digital ones are) will be fine for balancing.

Bull

They may read to 1 gram but that does NOT make then accurate to 1 gram

... but that doesn;t matter providing the scales read repeatedly. As I understand it, the idea to to make the components equal in weight not weigh

some pre-determined amount.

|

|

|

02GF74

|

| posted on 18/2/06 at 10:13 AM |

|

|

doh!! why didn't I think of that; obvious when you see it;

just bot up two rods end to end then rest on flat surface.

|

|

|