itguy

|

| posted on 9/9/06 at 09:09 PM |

|

|

Alternative Zetec alternator position.?

Hi Everyone

After fitting this:

I need to relocate my alternator - anyone done this on a zetec before / have any suggestions?

Thanks

Will.

|

|

|

|

|

DIY Si

|

| posted on 9/9/06 at 09:23 PM |

|

|

Could it run on the same belt as the supercharger, but pointing forwards?

“Let your plans be dark and as impenetratable as night, and when you move, fall like a thunderbolt.”

Sun Tzu, The Art of War

My new blog: http://spritecave.blogspot.co.uk/

|

|

|

Guinness

|

| posted on 9/9/06 at 09:26 PM |

|

|

I could be wrong, but don't you need a steering shaft to go there or thereabouts?

Nice blower BTW

Mike

|

|

|

itguy

|

| posted on 9/9/06 at 09:46 PM |

|

|

steering shaft - don't worry, its there, just the pics a bit dark - misses it by a mile

I could possibly mount it facing the opposite way round I suppose (back of the alternator into the nosecone) but I'd have to move my battery

(its smack band in the wrong place at the mo!) - Tis a possibility though..

|

|

|

DIY Si

|

| posted on 9/9/06 at 09:49 PM |

|

|

Ah, the shaft is just about visible!

Would it be possible to run another belt and put it on the near side?

“Let your plans be dark and as impenetratable as night, and when you move, fall like a thunderbolt.”

Sun Tzu, The Art of War

My new blog: http://spritecave.blogspot.co.uk/

|

|

|

itguy

|

| posted on 9/9/06 at 09:52 PM |

|

|

I expect thats where it will end up - Ive got my exhaust downpipes there though plus the engine mounting bracket at the bottom so its just trying to

find a place to squeeze it in!

I think in any case I'm going to have to swap the standard ford one for a smaller charade type one anyway.

|

|

|

DIY Si

|

| posted on 9/9/06 at 09:56 PM |

|

|

I'm not sure, but I thought I heard some thing about the cvh bracket being suitable for this?

“Let your plans be dark and as impenetratable as night, and when you move, fall like a thunderbolt.”

Sun Tzu, The Art of War

My new blog: http://spritecave.blogspot.co.uk/

|

|

|

itguy

|

| posted on 9/9/06 at 09:59 PM |

|

|

Interesting - for which bit? Fitting on the near side or fitting of the smaller alternator?

|

|

|

DIY Si

|

| posted on 9/9/06 at 10:01 PM |

|

|

I'm not sure, possibly both. The bracket normally sits on the offside, but it could probably be made to accept a smaller alternator too.

“Let your plans be dark and as impenetratable as night, and when you move, fall like a thunderbolt.”

Sun Tzu, The Art of War

My new blog: http://spritecave.blogspot.co.uk/

|

|

|

itguy

|

| posted on 9/9/06 at 10:15 PM |

|

|

Could do with a diagram/pic of the CVH mounting then.. .anyone got one?

|

|

|

DIY Si

|

| posted on 9/9/06 at 10:18 PM |

|

|

I do, but no idea where it is in the garage. I'll have a look tomorrow if no one else put a pic up. It allowed the alternator to be put quite

tight to the engine.

“Let your plans be dark and as impenetratable as night, and when you move, fall like a thunderbolt.”

Sun Tzu, The Art of War

My new blog: http://spritecave.blogspot.co.uk/

|

|

|

bimbleuk

|

| posted on 10/9/06 at 05:20 AM |

|

|

Any way you could add another idler pulley to increase your belt wrap on the supercharger? You want as much as possible to avoid belt slippage. As you

probably know theres quite a lot of power required to drive the SC under load.

[Edited on 10/9/06 by bimbleuk]

|

|

|

Ivan

|

| posted on 10/9/06 at 07:39 AM |

|

|

Why don't you make up a new alternator bracket for the other side of the engine - it will most probably mean fitting a double pully on the

crankshaft but that should be no big deal.

I agree with bimbleuk that you might need more belt contact on the supercharger - or maybe even a wider belt - as they need tens of horsepower to

drive.

Fitting a double pulley on the crank will give you a chance to widen the supercharger belt as well.

That being said you're in for serious fun when it gets on the road - nice one.

|

|

|

Ivan

|

| posted on 10/9/06 at 07:47 AM |

|

|

Having another look at your photo, if you fit a double pully as per my previous comment why not drive the water pump and alternator from the back

belt, move the supercharger forward and drive it from the front pully - this will give much more belt wrap - in the photo it looks like the

supercharger pully is much deeper then the belt you are using but I can't see properly.

|

|

|

big_wasa

|

| posted on 10/9/06 at 07:52 AM |

|

|

Westfield cvh mount that also fits a zetec.

it has the alternator mounts on it.

|

|

|

Monkeybasher

|

| posted on 10/9/06 at 05:08 PM |

|

|

Looks familiar . .

My supercharger is still running fine on my zetec. To be honest I haven't driven the car much, but when I have it has been driven hard and it

aint broke yet.

Unfortunatly I have lost my camera so I can't take anymore pictures.

I moved the small denso alternator to the other side, just under the exhaust. I made a braket secured with existing holes in the block. I had to

replace my water pump again as the pump with this new layout is driven the other way.

The other advantage of the layout as you get much more belt around the charger eliminating slip.

I am still messing around with different charge coolers and radiators to get inlet temps down. They are down to around 40-50c now. Although under

bonnet temps are incredibly high even with my new holes in the bonnet. The footwells on a hot day are boiling.

With the chargecooler radiator sitting in front of my engine radiator the engine temps have been creeping up with hard driving. I have a polo rad

ready to be fitted, hopefully this will help.

I am still using silicon pipes which need replaced for hard ones as they collapse off boost.

I secured the charger with threaded rod as you have, they both sheared. I have replaced the threaded rod with better quality stuff hopefully it will

be ok. If it shears again then I may be able to drill the charger holes biggar.

As for mapping I very much a novice and have only mapped using megasquirts auto tune and retarded boost 1 degree for every 1 psi above 100kpa. At

100kpa its 30degrees.

To be honest I got fed up wasting away my summer constantly pissing about with the laptop different chargecooler/radiator setups, so said sod it that

will do and have just been enjoying driving it. Apart from starting the car runs fine.

Very pleased with the result though its worth the effort

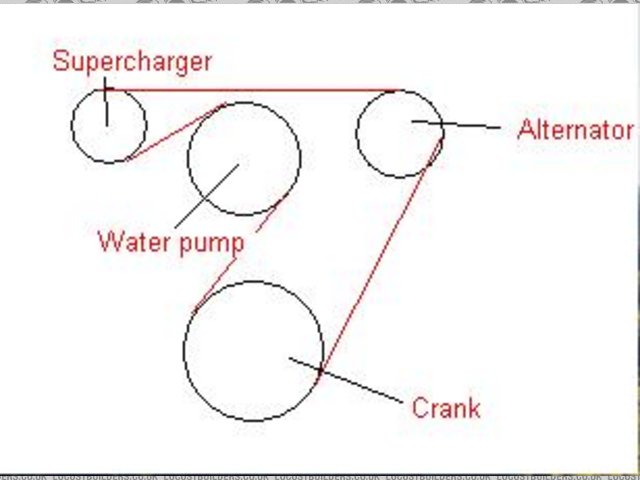

Since my camera is missing I have made a very rough drawing of my new drive belt layout. Hope this helps

Steve

|

|

|

Monkeybasher

|

| posted on 10/9/06 at 05:12 PM |

|

|

1

Rescued attachment sdrtg.JPG

|

|

|

itguy

|

| posted on 10/9/06 at 08:51 PM |

|

|

Fantastic to hear its still working ok - I sure can't wait to get mine up and running...

Now I've got the charger mounted I can start to plan all of my other things like inlet/outlet hoses/plenum etc - as you can see I've to

Jenveys on mine so it is a bit different to your setup.

Have you plumbed in a recirculating dump valve yet? I'm planning to do this from the outset to help with the hose colapsing thing and also the

back-pressure when coming off WOT.

I've been looking at the standard black plastic bosch type that is used on the VAG 1.8T engines and also some SAABs too - vacuum operated and

looks straight forward to plumb in.

After the alternator re-position problem is sorted out I'm next onto the outlet plate for the charger with the 60mm pipe welded on, then the

inlet plenum needs to be made up!

Fun fun fun!!

|

|

|

itguy

|

| posted on 10/9/06 at 08:53 PM |

|

|

oooo - just saw your line about the sheared threaded rod... blimey, that could have been serious!!

How many fixing points are you using on the charger? I'm using 4 - two M10 and two M8 (M10 at the back, M8 at the front).

I've got these bolted down onto a large flat plate thats then bolted using 4 M10s to the engine block.

I'm planning on making up 'perfect length' spacers to fit in-between the charger and the face of my mounting plate to eliminate any

slop. Ideally I'd like to find some bolts which are the correct length too.

Will.

|

|

|

stevebubs

|

| posted on 10/9/06 at 11:09 PM |

|

|

Useful diagrams here...

http://www.sylva.co.uk/technical/alternate.htm

|

|

|