NS Dev

|

| posted on 10/11/06 at 08:56 AM |

|

|

How is oil/grease kept in chain drive modded diffs?

Oh no, yet more chainy stuff!!!!

Just a quick one!

I have seen, and been told about several diffs, modified to run in block mounted bearings, with a sprocket on the crownwheel location, in chain drive

applications.

These have all been fitted with an enclosure over the diff carrier, to contain oil/grease etc.

How does this work????

I understand the obvious, but there appears to be no seal between the output shafts and the "enclosure".

There are a number of mentions of sealing the enclosure to the carrier, but that is the easy bit!!! What about when the diff is "diffing"

and therefore the outputs are not rotating at the same speed as the casing, surely the oil/grease can leak round the back of the output gears, along

the output shafts and out into the open air!?????

I know that it will "tend" not to as the output shafts are a reasonable fit in their splines, and the output gears usually sit on bronze

washers in the diff housing which will tend to seal them, but I don't usually build things on "tendencies"......I prefer

certainties!

How is the oil prevented from leaking out down the outside of the output shafts??

Retro RWD is the way forward...........automotive fabrication, car restoration, sheetmetal work, engine conversion

retro car restoration and tuning

|

|

|

|

|

flak monkey

|

| posted on 10/11/06 at 09:03 AM |

|

|

I am not sure, but if you cant get an answer i can have a look and see how we do it.

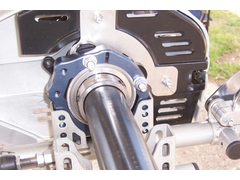

Last years cars diff looked like this:

Mind you, having said that it leaked a bit around where the sprocket was bolted on, but thats a simple fix.

David

Sera

http://www.motosera.com

|

|

|

nitram38

|

| posted on 10/11/06 at 09:06 AM |

|

|

How many teeth on that sprocket?

|

|

|

NS Dev

|

| posted on 10/11/06 at 09:22 AM |

|

|

oh to have a vertical mill........really must get myself one sorted out!!!

Retro RWD is the way forward...........automotive fabrication, car restoration, sheetmetal work, engine conversion

retro car restoration and tuning

|

|

|

iank

|

| posted on 10/11/06 at 09:23 AM |

|

|

Some information here, but probably not detailed enough.

http://www.westhouse.plus.com/chaindrive1.htm

|

|

|

NS Dev

|

| posted on 10/11/06 at 09:24 AM |

|

|

no, just been looking there! He mentions rtv sealant to seal the can to the carrier, but nothing of sealing the can/carrier to the outputs!!

Retro RWD is the way forward...........automotive fabrication, car restoration, sheetmetal work, engine conversion

retro car restoration and tuning

|

|

|

cloudy

|

| posted on 10/11/06 at 09:34 AM |

|

|

Probably about same as mine - 52ish

Gives a 4:1 with a 13tooth sprocket

as regards sealing, yeah interesting to know, it wouldn't flood out through the holes here but certainly must leak slowly. maybe a very thin o

ring between the faces would be enough to do it and still allow the circlips to be installed to hold driveshafts in?

Something I have to figure out for my own diff too

James

[Edited on 10/11/06 by cloudy]

[Edited on 10/11/06 by cloudy]

|

|

|

Minicooper

|

| posted on 10/11/06 at 10:09 AM |

|

|

They certainly weap a bit, that's the main reason they probably recomend either heavy oil or grease. If you put the proper oil in, it would be

everywhere.

Some people have put the original oil seal on the outside of the bearing carrier, which would mean a machined carrier, still would weap a bit from the

other side of the bearing but would help.

I think someone said that VW diffs have an internal oil seals in the outputs

Cheers

David

[Edited on 10/11/06 by Minicooper]

|

|

|

NS Dev

|

| posted on 10/11/06 at 10:28 AM |

|

|

cheers folks!

Sounds like I wasn't missing something obvious then!

I know I have seen diffs on grassers, where they have used and English or atlas lsd casing, with circular bits welded into the casing holes, with one

drilled and tapped for a grease nipple and another with a drain bung in it of some sort, but I never got an answer to the oil sealing!.

thanks again

Nat

Retro RWD is the way forward...........automotive fabrication, car restoration, sheetmetal work, engine conversion

retro car restoration and tuning

|

|

|

uklee70

|

| posted on 10/11/06 at 10:29 AM |

|

|

If you are building a grasser

you don't use a diff do you?

When I built my Mini at z cars the grasser with twin engines had no diff

|

|

|

NS Dev

|

| posted on 10/11/06 at 10:36 AM |

|

|

No, no diff on this project, but I am always thinking!!!

The idea at the mo for the grasser is either use a sierra diff, welded up, mounted in bearings with a sprocket on the crownwheel mounting face, or, if

I can sort a drawing, spark erode (we have a cnc eroder at work) some internally splined bosses to take sierra output stubs and do it that way.

The latter would avoid the weight of the sierra diff, but mean more work!

I think it will end up being the sierra diff with welded up side gears............agricultural but functional............

and my degree was in agricultural engineering after all!!

Retro RWD is the way forward...........automotive fabrication, car restoration, sheetmetal work, engine conversion

retro car restoration and tuning

|

|

|

MikeR

|

| posted on 10/11/06 at 01:00 PM |

|

|

why not take the gubbings from a sierra diff (ie internally splined bits) throw the rest away and weld them together.

You don't need input or crownwheel, casing etc so why carry them?

|

|

|

NS Dev

|

| posted on 10/11/06 at 01:04 PM |

|

|

I need something to mount the sprocket to though and the gears are not really weldable steel. When the weld is more just "locking" than

under full force this method works ok, but I couldn;t just weld the side gears to a home fabbed carrier and expect the welds to hold

Retro RWD is the way forward...........automotive fabrication, car restoration, sheetmetal work, engine conversion

retro car restoration and tuning

|

|

|

nitram38

|

| posted on 10/11/06 at 01:33 PM |

|

|

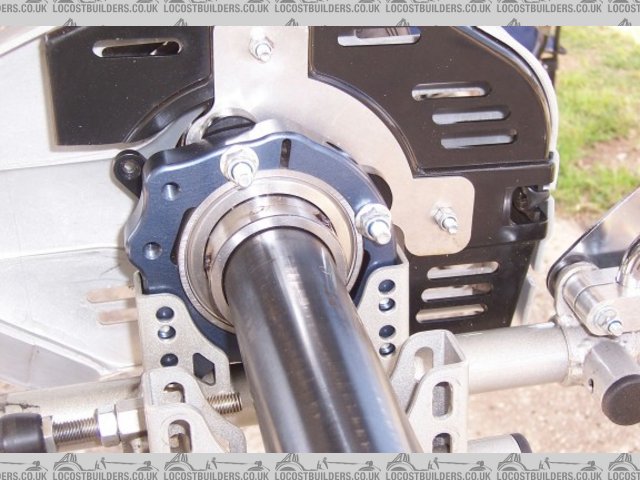

I bought this sierra 4 X 4 "lsd" diff from a member on here who bought it from Z Cars.

Shouldn't be too difficult to make yourself.

I just need a 52 tooth cog.....If anyone has one

diff1

[img][/img]

|

|

|

NS Dev

|

| posted on 10/11/06 at 03:26 PM |

|

|

quote:

Originally posted by nitram38

I bought this sierra 4 X 4 "lsd" diff from a member on here who bought it from Z Cars.

Shouldn't be too difficult to make yourself.

I just need a 52 tooth cog.....If anyone has one

diff1

diff2

You could't find me a maker and part no. on the bearings could you?

Would help speed my job up if ya can!

cheers

Nat

Retro RWD is the way forward...........automotive fabrication, car restoration, sheetmetal work, engine conversion

retro car restoration and tuning

|

|

|

Minicooper

|

| posted on 10/11/06 at 03:33 PM |

|

|

There were no markings at all, I had a really good look.

I don't know wether they had been ground off

David

|

|

|

cloudy

|

| posted on 10/11/06 at 04:03 PM |

|

|

Z cars are bastids and will only reply to your emails if they sniff some possible cash. So instead I worked out what they'd used myself...

The bearings I have used are UCPA-50 (50mm)

with the SA210 insert (to make it thin enough not to foul on the flanges) with the ecentric ring removed.

£12.79 ex vat each from Midland Bearings

You'll then need to turn up a spacer to match the sierra diff as it's a really odd size - I couldn't find a bearing to exactly match

something like this:

http://www.digital-car.co.uk/wr4/87.jpg

(ignore bearing in background that one was too wide!!)

Will get some photos of the completed setup too.

Btw B&C Express made up my 52tooth sprocket to match the sierra diff

James

[Edited on 10/11/06 by cloudy]

[Edited on 10/11/06 by cloudy]

|

|

|

NS Dev

|

| posted on 10/11/06 at 04:22 PM |

|

|

Oh that is superb Cloudy!!! Just the info I needed, saved me loads of work!!

How much did you pay for the sprocket, out of interest?

Retro RWD is the way forward...........automotive fabrication, car restoration, sheetmetal work, engine conversion

retro car restoration and tuning

|

|

|

cloudy

|

| posted on 10/11/06 at 04:33 PM |

|

|

I'll have to check for exact price but I believe it was about £40 shipped

James

|

|

|

cloudy

|

| posted on 10/11/06 at 04:46 PM |

|

|

forgot to mention - bearing specs are here:

http://www.fk-bearing.com/eBusiness/en/index.asp

they reference it as a UCPA210 instead of ucpa-50, same unit. midland can supply the alternate insert though - the standard bearing is way too wide

Midland seem to have most in stock...

[Edited on 10/11/06 by cloudy]

|

|

|

Fred W B

|

| posted on 11/11/06 at 03:36 PM |

|

|

Was at the kart track today, so took a photo of a 50 mm kart axle bearing carrier.

Note this kart is partially assembled, the bearing carrier is missing the bolts that secure it to the chassis

Cheers

Fred W B

50mm

[Edited on 11/11/06 by Fred W B]

|

|

|

NS Dev

|

| posted on 13/11/06 at 09:37 AM |

|

|

quote:

Originally posted by cloudy

forgot to mention - bearing specs are here:

http://www.fk-bearing.com/eBusiness/en/index.asp

they reference it as a UCPA210 instead of ucpa-50, same unit. midland can supply the alternate insert though - the standard bearing is way too wide

Midland seem to have most in stock...

[Edited on 10/11/06 by cloudy]

you have U2u, I'm confused!

Retro RWD is the way forward...........automotive fabrication, car restoration, sheetmetal work, engine conversion

retro car restoration and tuning

|

|

|